Corrugated plate-ECC fabricated composite column and construction method thereof

A construction method and corrugated plate technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of low industrialization, lack of standardization of building structures, and mechanical obstacles in construction, so as to reduce steel bar binding, not easy to peel off, and ensure Integrity and Seismic Performance Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

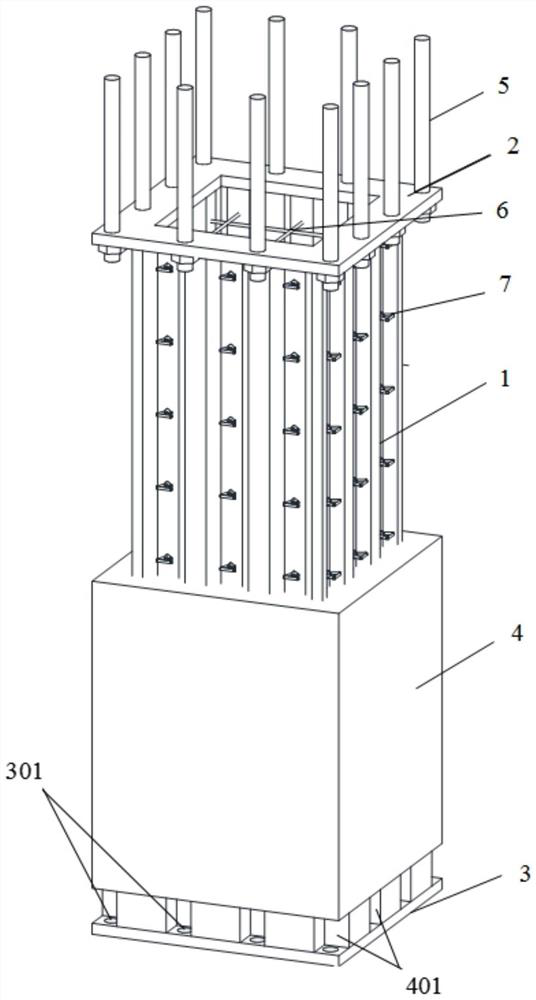

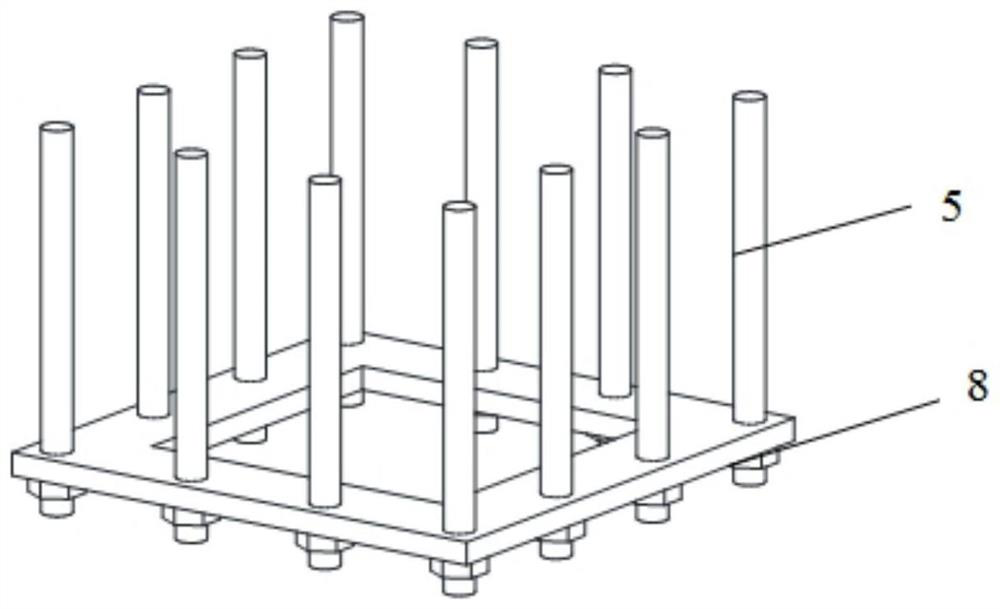

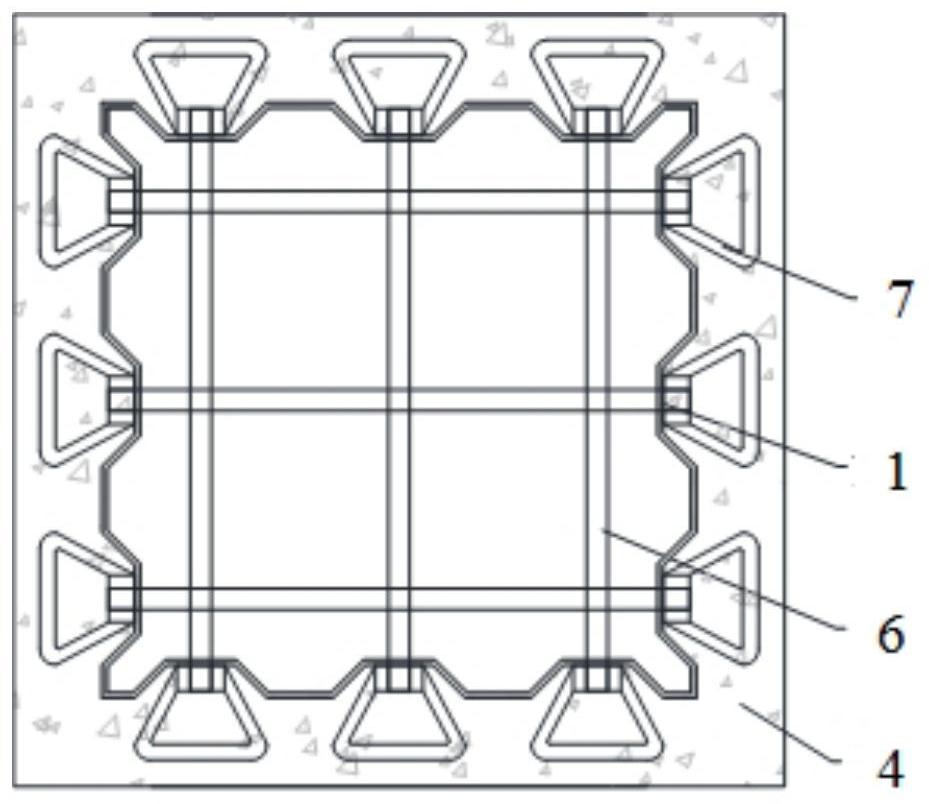

[0023] Such as figure 1 As shown, a corrugated plate-ECC assembled composite column includes a hollow cylindrical corrugated plate inner shell 1 , an upper end plate 2 , a lower end plate 3 , an ECC outer shell 4 and a plurality of connecting rods 5 . The upper end plate 2 and the lower end plate 3 are respectively welded to the two ends of the corrugated plate inner shell 1 . The upper end plate 2 is parallel to the lower end plate 3 and both are perpendicular to the axial direction of the corrugated plate inner shell 1 . The connecting rod 5 is vertically fixed to the upper end plate 2 . The lower end plate 3 is provided with a plurality of through holes 301 , and each of the connecting rods 5 can correspond to one of the through holes 301 along its axial direction. The ECC outer shell 4 is solidified and wrapped around the side wall of the corrugated plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com