Wallboard assembled air duct

A kind of assembly type and wall panel technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as insufficient strength, impact on service life, and creases on the outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

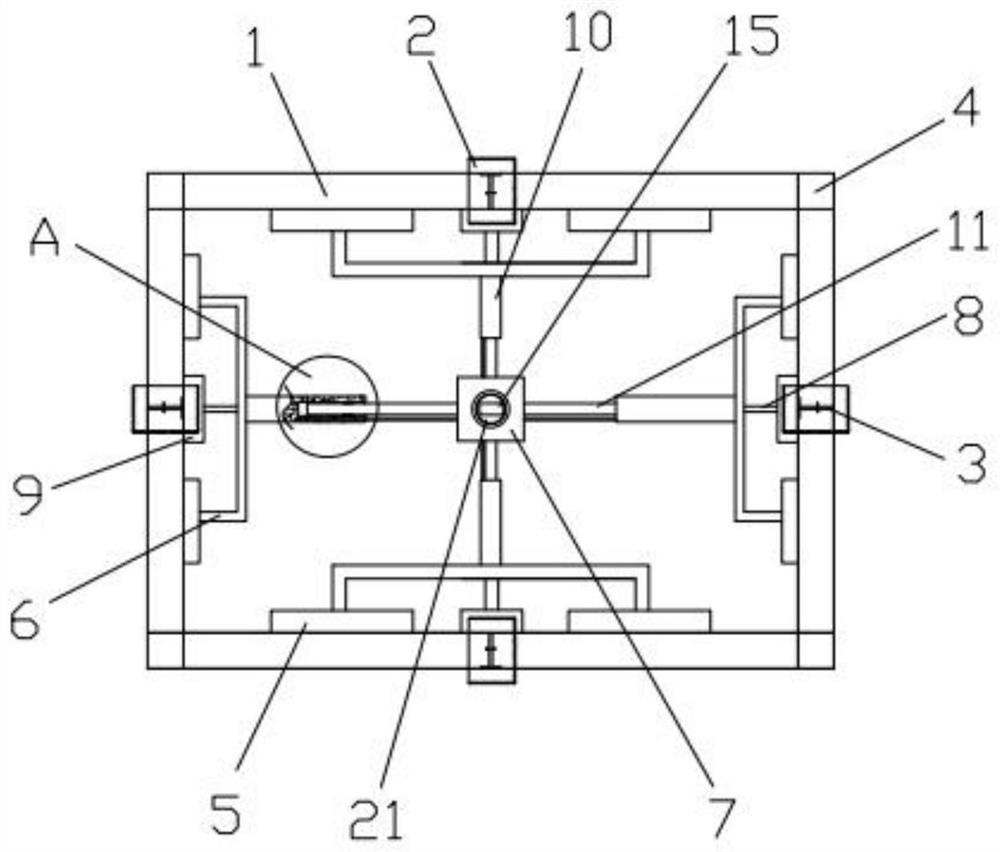

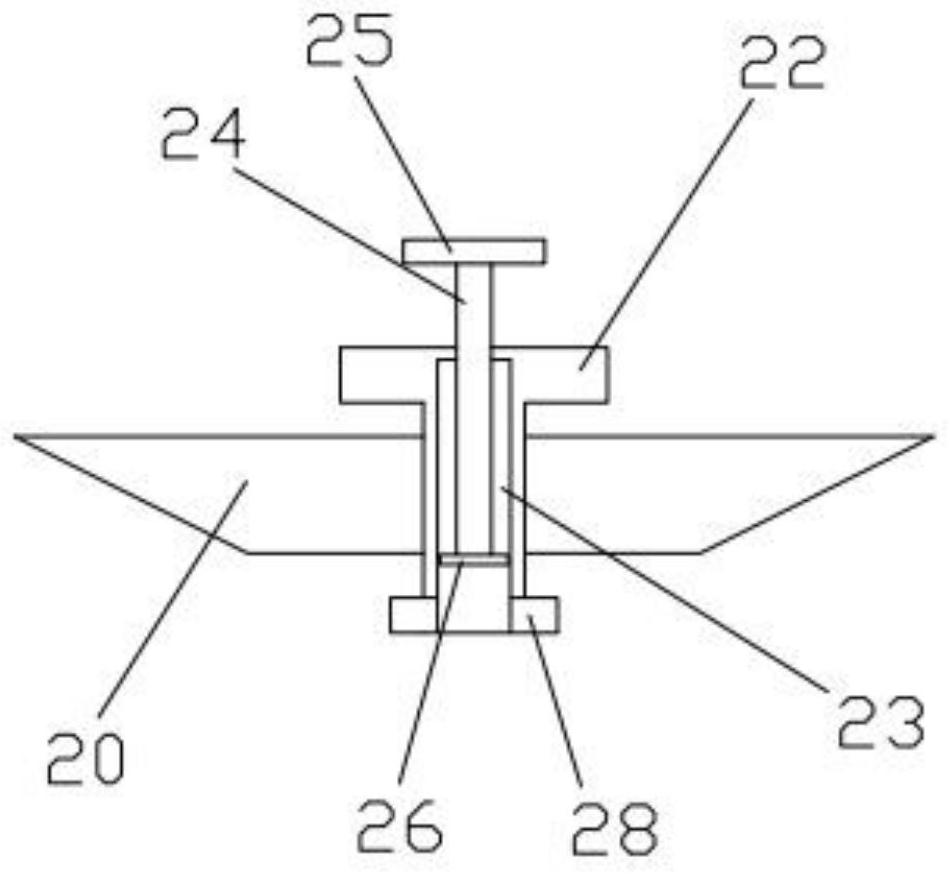

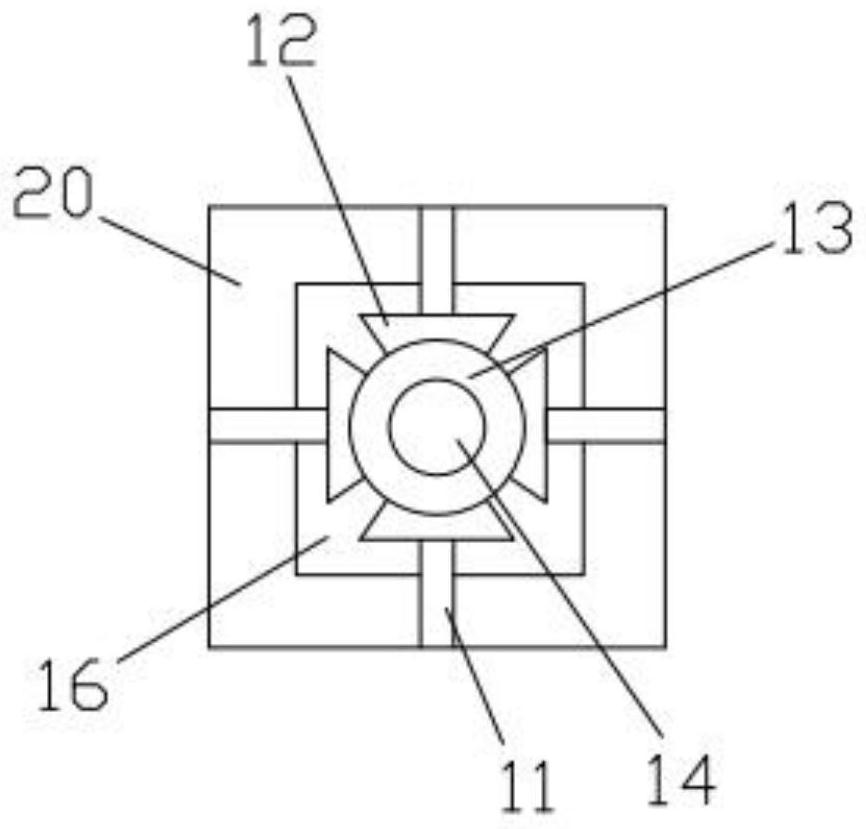

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0019] Such as Figure 1 to Figure 4 An assembled air duct with wall panels 1 is shown, including wall panels 1, bolts 2 cooperating with the wall panels 1, and sealing backing plates 3 with a T-shaped structure arranged between adjacent wall panels 1 , the air duct is formed by connecting four sets of wall plates 1, and the adjacent wall plates 1 are fixed by bolts 2. It should be noted that each set of wall plates 1 is subjected to bending treatment respectively. Corner piece 4 is provided at the bending place.

[0020] Compared with the existing air duct structure, the air duct structure is assembled by assembling the wall panels 1, which can save the welding process, has a beautiful appearance, is convenient to disassemble, and is convenient for maintenance, storage and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com