Track lamp

A track light and lamp tube technology, applied in the field of track lights, can solve the problems of high production cost, complex structure, difficulty in adapting to the assembly requirements of LED light sources with different powers, etc., achieve low production cost, increase specific surface area, and facilitate assembly and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above is only a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications should also be It is regarded as the protection scope of the present invention. The structures, devices and operation methods not specifically described and explained in the present invention, unless otherwise specified and limited, shall be implemented according to conventional means in the art.

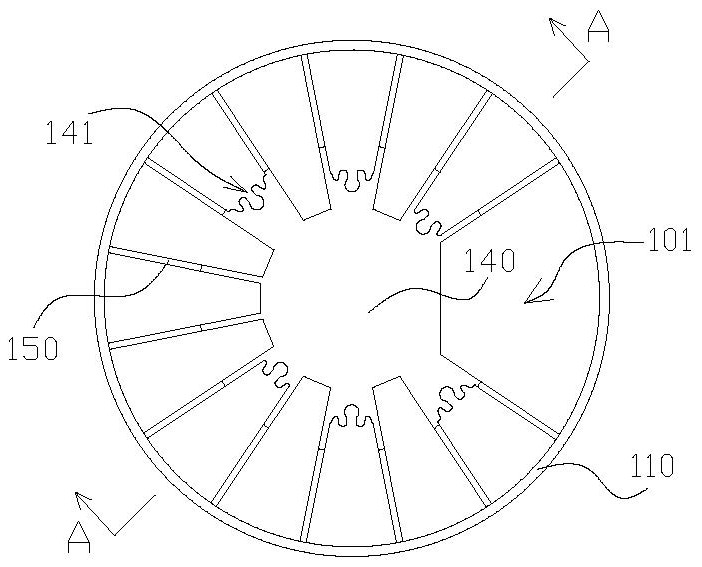

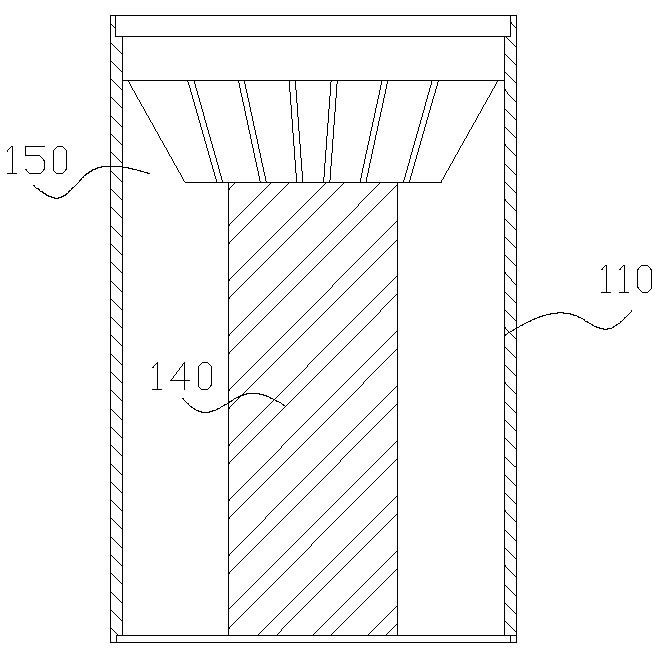

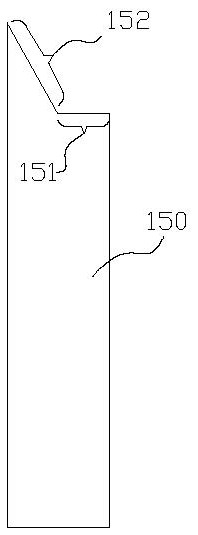

[0044] Such as figure 1 , 2 As shown in , 3 and 4, a track light 100 includes a lamp body 110. A heat dissipation structure is arranged on the lamp body 110. The heat dissipation structure has an installation part for installing the LED light source 120. The installation part is provided with an A installation structure, the LED light source 120 is fixedly installed on the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com