Assembly type embedded pipeline integrated partition wall board and method

A technology of pre-embedded pipelines and pipes, which is applied to walls, building components, ceramic molding machines, etc., can solve the problems of waste of materials, many processes interspersed, and hidden dangers of wall cracking quality, so as to reduce processes, improve product quality, Avoiding the effects of pipeline grooving construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

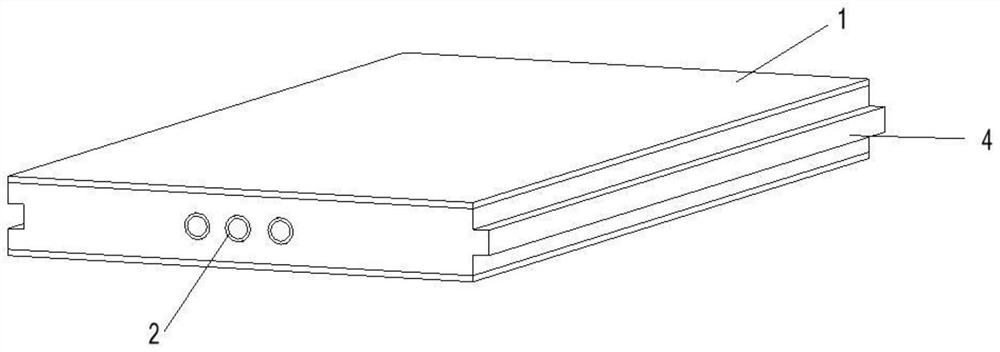

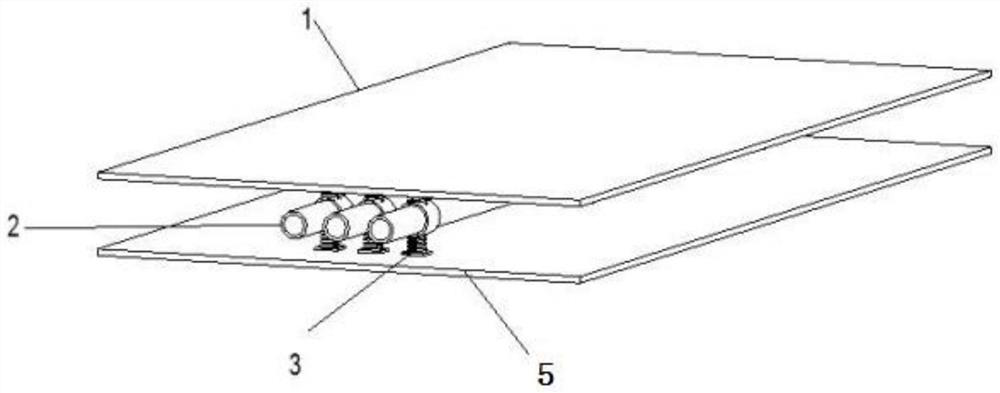

[0063] as Figures 1 through 6 As shown, the above-described prefabricated embedded pipeline integrated partition wall plate production method, including the following steps:

[0064] Step 1, the embedded tube 2 into the socket 31 of the positioner 3.

[0065] Specifically, the casing 31 may use a galvanized tube, and the length of a single galvanized tube is not less than 2.4m.

[0066] Step 2, the first panel 1 fixed, a fixed card 32 of the locator 3 and the first panel 1 connected, another fixed card 32 of the positioner 3 and the second panel 5 connected, adjust the distance between the first panel 1 and the second panel 5 to the set value, and then fix the second panel 5.

[0067] Specifically, the embedded tube 2 is a straight tube, both ends of the buried tube 2 are flush with the first panel 1 and the second panel 5 end faces, the fixed panel and the positioner 2 of the installed embedded tube 2: the first panel 1 is fixed, a fixed card 32 of the positioner 3 is installed wi...

Embodiment 2

[0073] as Figure 7 As shown, the above-described prefabricated embedded pipeline integrated partition wall plate production method, including the following steps:

[0074] Step 1, the embedded tube 2 into the socket 31 of the positioner 3.

[0075] Step 2, fix the panel and install the positioner 2 of the embedded tube 3: the first panel 1 is fixed, a fixed card 32 of the positioner 3 and the first panel 1 is installed in the middle of the positioner 3 and the embedded tube 2, the positioner 3 and the first panel 1 are temporarily fixed with adhesive, according to the thickness requirements of the wall panel, fix the second panel 5. Wherein, the embedded tube 2 is a straight tube, one end of the buried tube 2 is flush with the end face of the first panel 1 and the second panel 5, and the outside of the other end of the buried tube 2 is reserved with a connection chamber 11, so that the other end of the buried tube 2 is connected to the external pipeline, and then the pipeline is p...

Embodiment 3

[0080] as Figure 8-10 As shown, the above-described prefabricated embedded pipeline integrated partition wall plate production method, including the following steps:

[0081] Step 1, the embedded tube 2 into the socket 31 of the positioner 3.

[0082] Step 2, fix the panel and install the positioner 2 of the embedded tube 3: the first panel 1 is fixed, a fixed card 32 of the positioner 3 and the first panel 1 is installed in the middle of the positioner 3 and the embedded tube 2, the positioner 3 and the first panel 1 are temporarily fixed with adhesive, according to the thickness requirements of the wall panel, fix the second panel 5. Wherein, one end of the buried tube 2 is connected to the elbow 7, the other end of the buried tube 2 is flush with the end face of the first panel 1 and the second panel 5, and the external setting of the elbow 7 is wired box 8, to achieve the pipeline from the first panel 1 or the second panel 5 through.

[0083] Step 3, install the barrier plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com