Photoacoustic gas sensor device

A sensor device, photoacoustic gas technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long optical path length, complexity, large size of photoacoustic gas sensor, etc., to achieve stable construction and not easy to mechanical instability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The same elements are denoted by the same reference numerals in all figures.

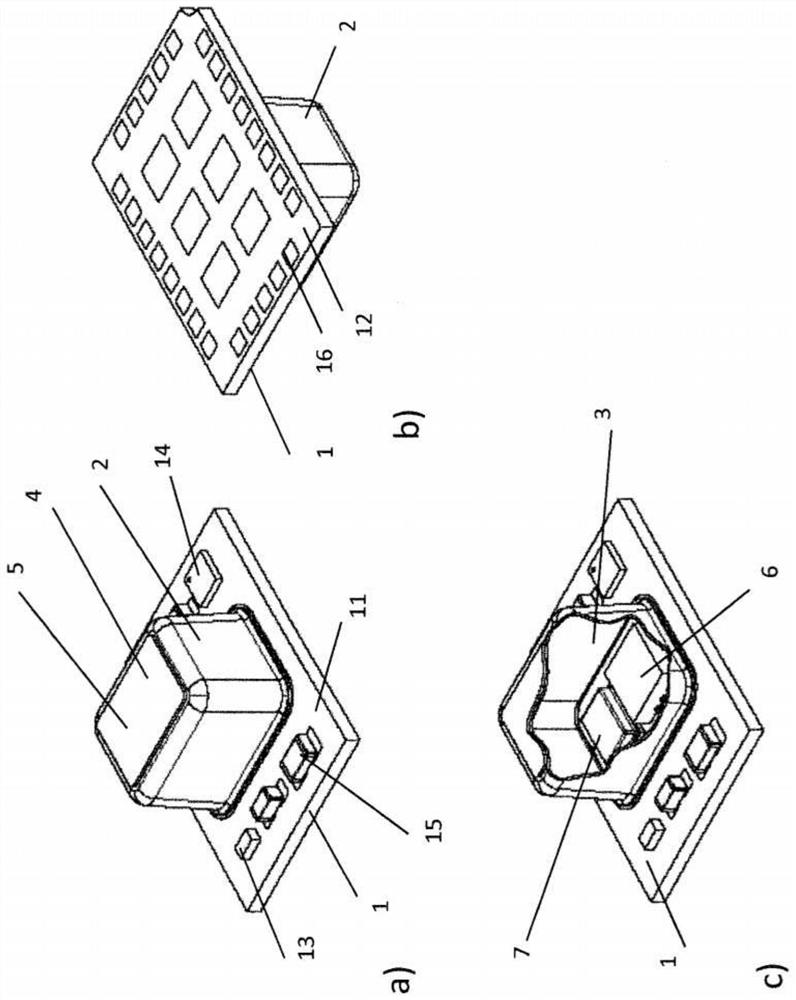

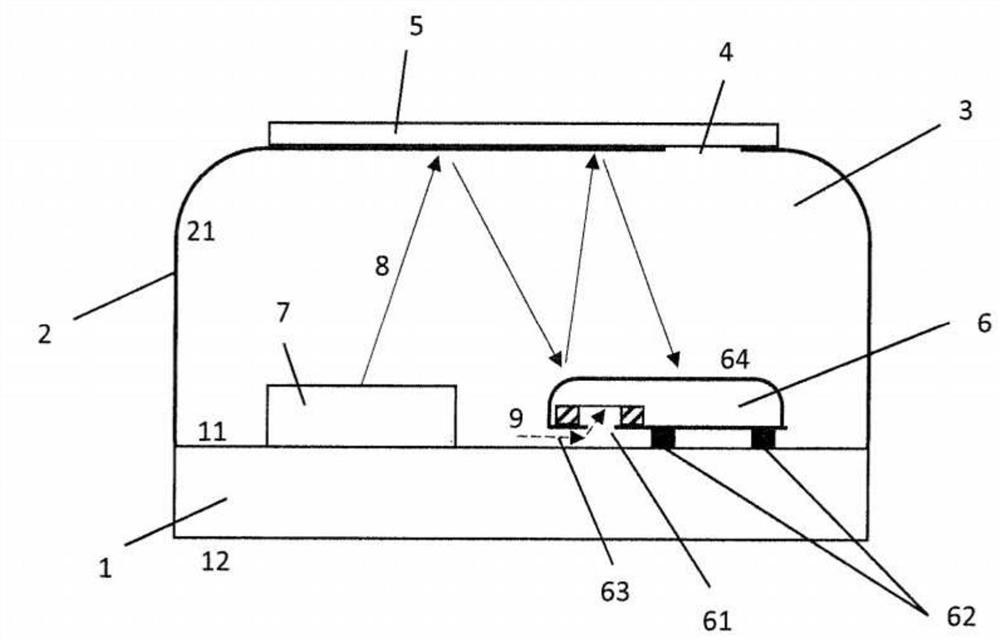

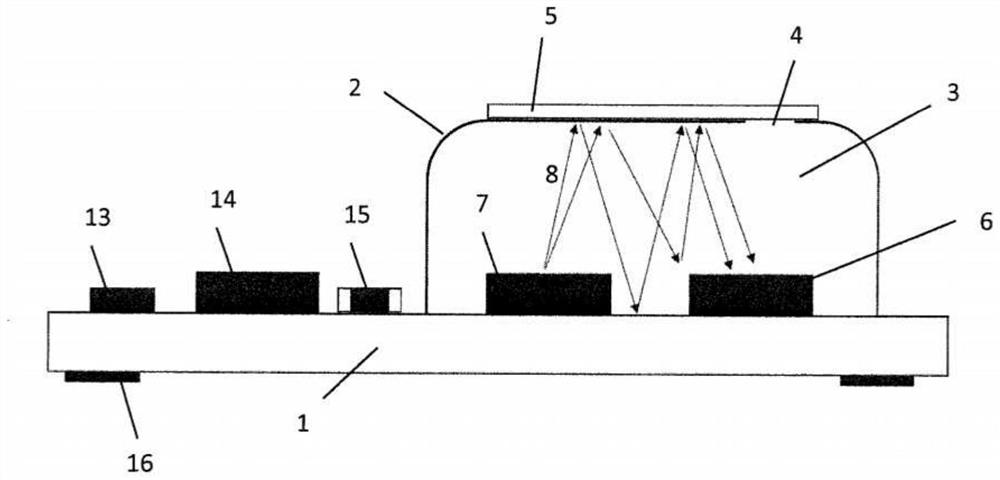

[0035] figure 1 A perspective view of a photoacoustic gas sensor device according to an embodiment of the invention is shown from above and from below. The device comprises a substrate 1 , eg a printed circuit board (PCB), and a measuring cell body 2 , which together form a measuring cell surrounding a measuring volume 3 . The measuring cell has holes 4 to allow gas exchange between the measuring volume 3 and the surroundings of the device. exist figure 1 In, the hole 4 is located in the main body 2 of the measuring cell. The pores 4 are preferably covered by a membrane 5 which is gas permeable to allow gas exchange such that the concentration of the component of interest in the gas is similar to that in the environment.

[0036] The substrate 1 has a first side 11 and a second side 12 . On the first side 11 the measuring cell body 2 is arranged, as well as the other parts described belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com