Hanging equipment for down jacket production

A suspension device and down jacket technology, which is applied in the field of suspension equipment for down jacket production, can solve problems such as increasing the length of shoulder support, separation and falling of down jackets, and increased folds under the arms of down jackets, so as to reduce vibration amplitude, ensure stability, and reduce wrinkles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

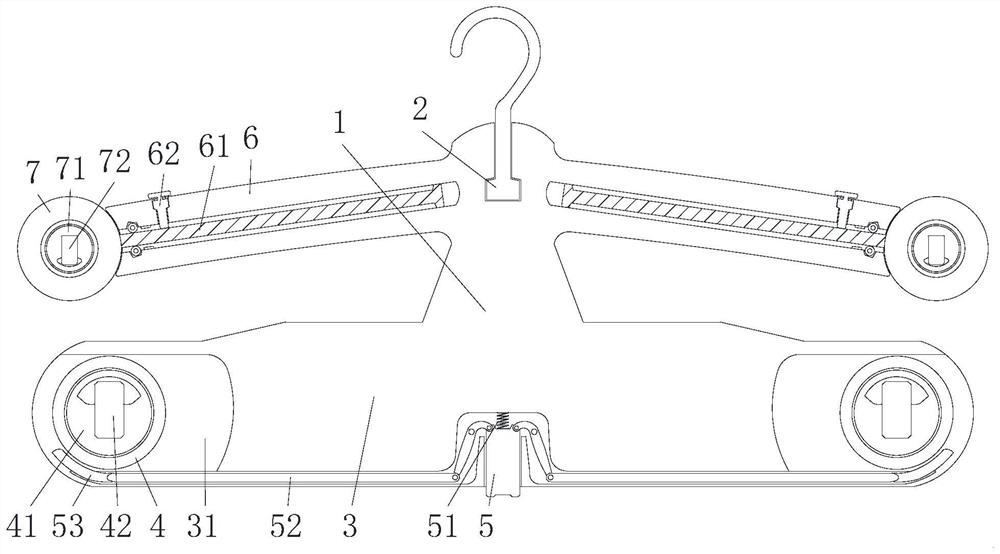

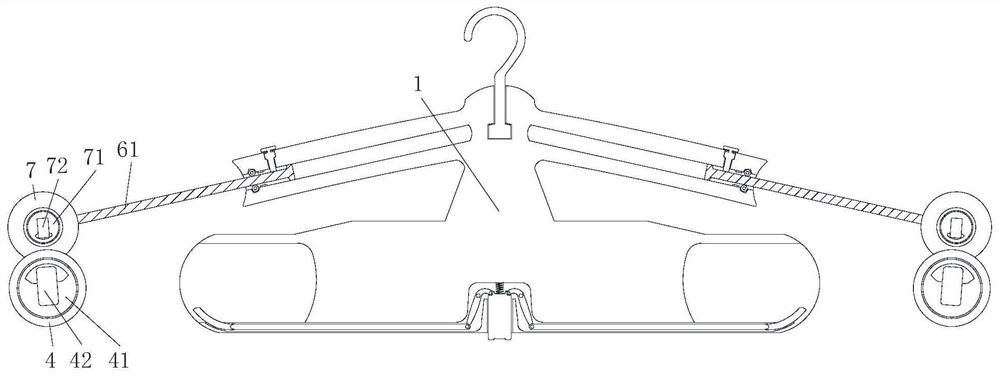

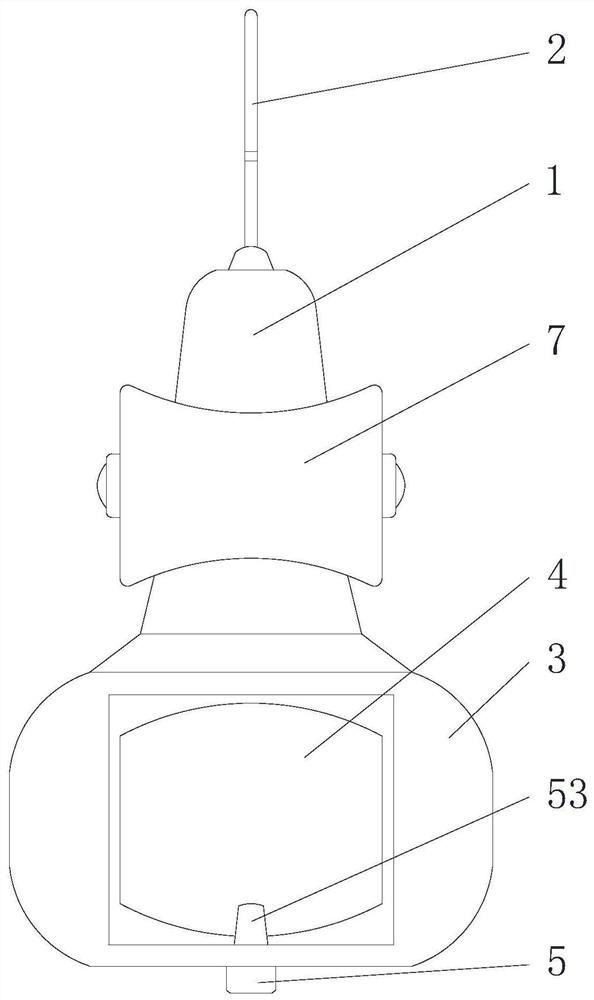

[0025] Such as Figure 1-4 As shown, the suspension equipment for the production of down jackets in this embodiment includes a center frame body 1, a hook 2, a shoulder brace 3 and a telescopic frame 6, the hook 2 is located on the top of the center frame body 1, and the shoulder brace 3 Symmetrically arranged on both sides of the center frame body 1, the outer side of the shoulder bracket 3 is provided with a receiving groove 31, the inside of the receiving groove 31 is provided with a magnetic convex roller 4, and the inside of the convex roller 4 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com