A processing machine for punching and cutting corners of thin steel

A processing machine and angle cutting technology, applied in the field of thin steel plate manufacturing, can solve problems such as manual adjustment of molds, and achieve the effects of improving fixed position, accurately positioning local stamping deformation, and reducing cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

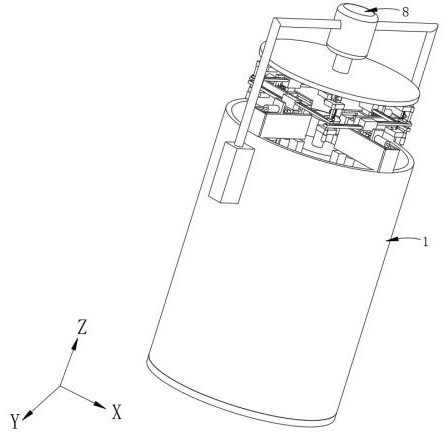

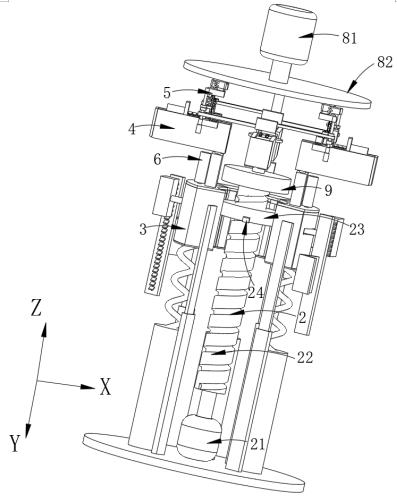

[0077] like Figure 1-2 Shown, a kind of thin steel stamping corner cutting processing machinery, including:

[0078] Stamping cylinder 1;

[0079] The transmission assembly 2 is arranged above the top of the inner wall of the stamping cylinder 1;

[0080] The engaging assembly 3 is slidably connected with the transmission assembly 2;

[0081] Fastening assembly 4, which is arranged on the top of punching cylinder 1 and is connected with transmission assembly 2;

[0082] Stamping component 5, it is arranged on the top of fastening component 4, and is connected with fastening component 4;

[0083] An air pressure component 6, which is connected with the engaging component 3;

[0084] A pressure assembly 7, one end of the pressure assembly 7 is connected to the fastening assembly 4, and the other end is connected to the air pressure assembly 6 through a pressure hose 74;

[0085] When the transmission component 2 drives the engaging component 3 to move downward, it drives t...

Embodiment 2

[0115] like Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

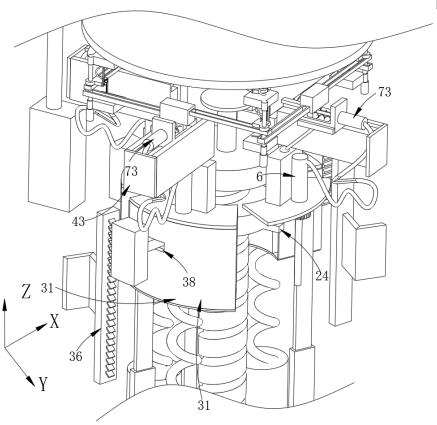

[0116] like Figure 13 As shown, preferably, the stamping assembly 5 includes:

[0117] The positioning chute rod 57 is arranged on both sides of the top of the pressure piston 71, and the surface is provided with a through groove 58, and the vertical direction overlaps between adjacent positioning chute rods 57;

[0118] Angle-cut positioning seat 54, which is located above the intersection of two adjacent positioning chute bars 57, and is slidably connected with two adjacent through grooves 58 through a slide bar 59;

[0119] Stamping upper seat 53, which is connected with the top of slide bar 59, is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com