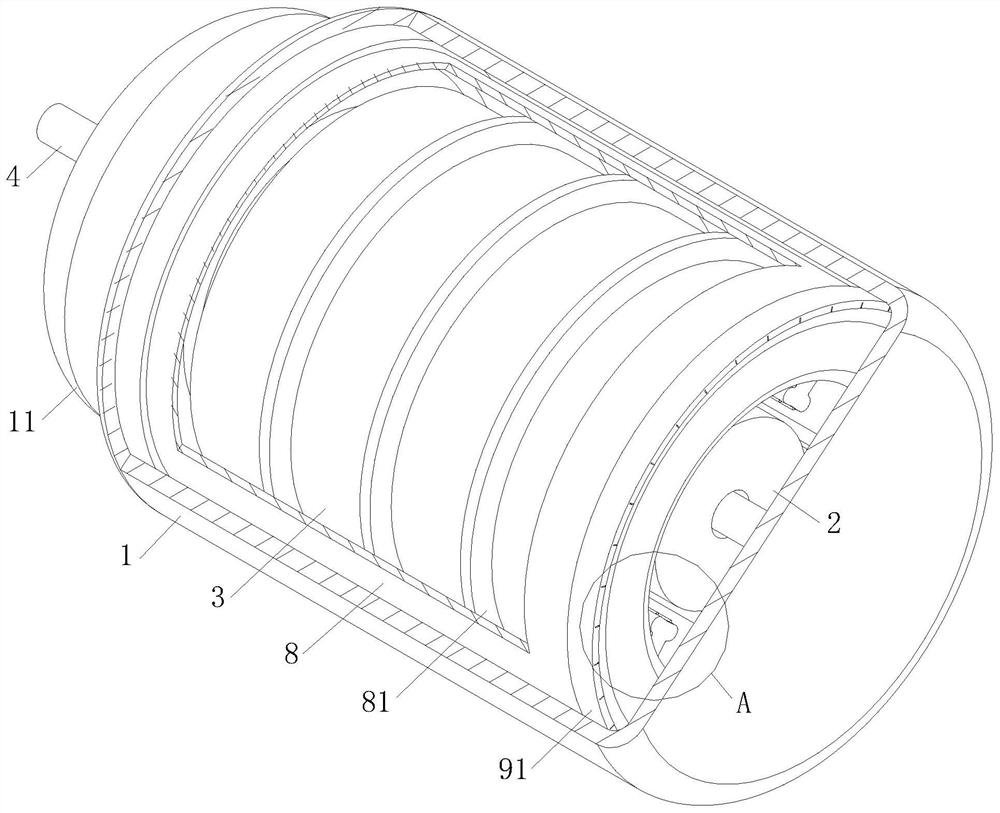

High-temperature superconducting hybrid magnetic levitation permanent magnet variable frequency motor

A technology of high-temperature superconducting and variable-frequency motors, applied in the direction of electrical components, magnetic attraction or thrust holding devices, etc., can solve the unresolved environmental temperature effects of motors, destroy the operating conditions of high-temperature superconducting states, and affect the state of high-temperature superconducting, etc. problems, to achieve the effect of isolating heat transfer, avoiding wear, and enhancing the degree of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

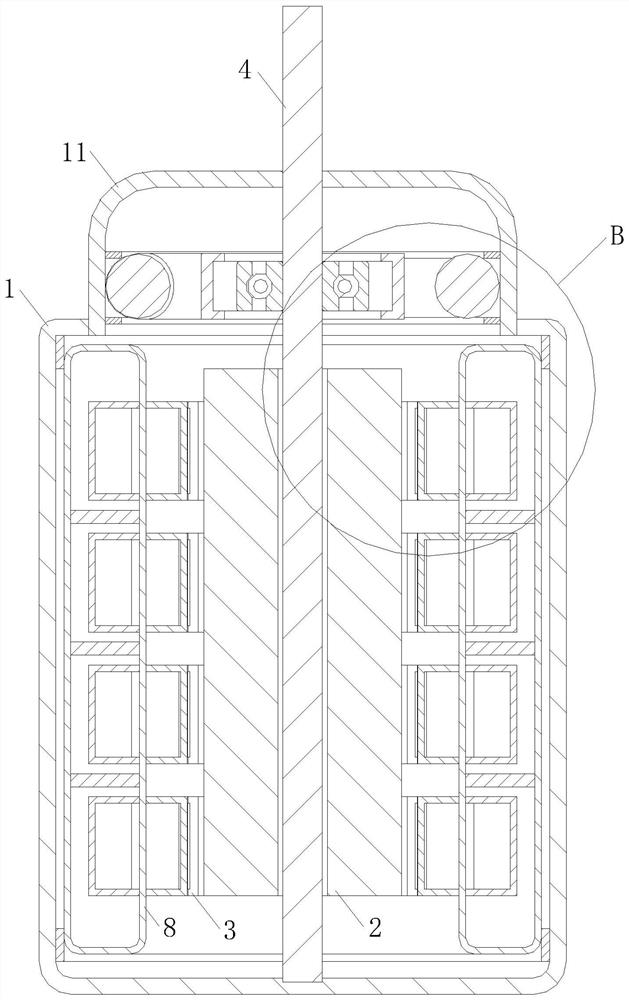

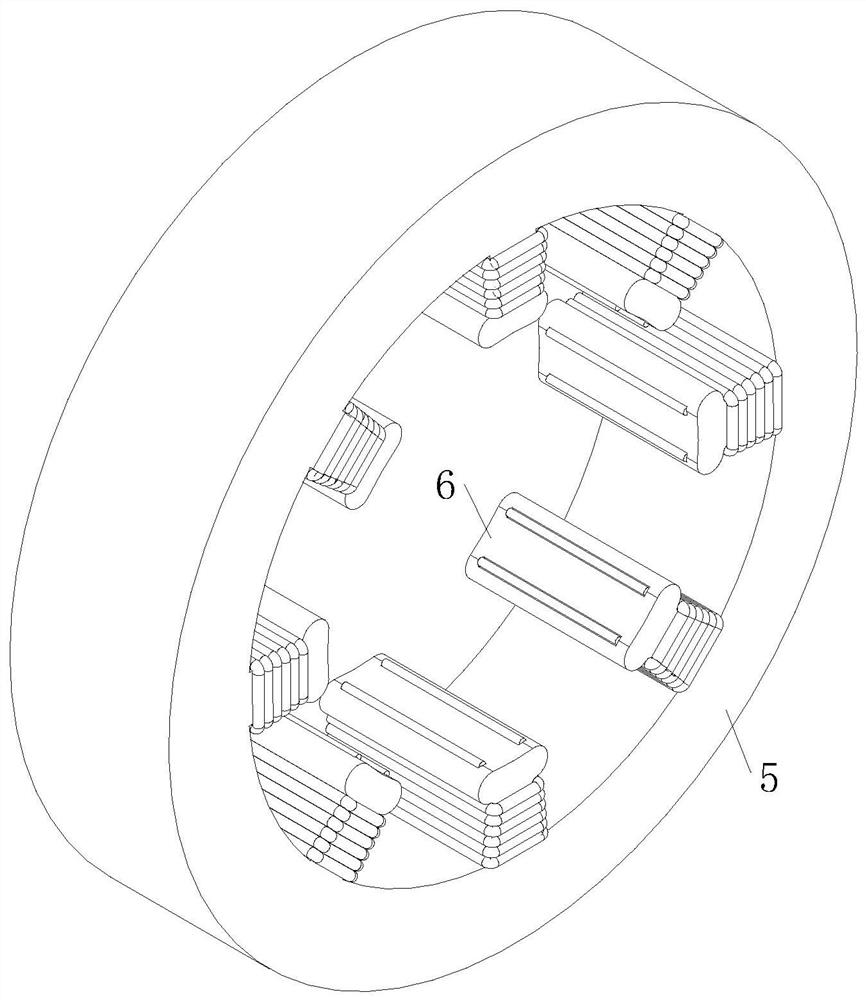

[0028] As an embodiment of the present invention, the inside of the superconducting block 6 is provided with an empty groove 63, and the bottom of the superconducting block 6 is fixed on the superconducting ring 5; the empty groove 63 extends along the superconducting block 6 to The inside of the superconducting ring 5; a grid ring 81 is arranged in the gap 7 stacked between the superconducting rings 5, and the grid ring 81 is fixed inside the ring tube 8; the electromagnetic field generated in the high temperature superconducting state is passed through the superconducting stator 3 The low-temperature effect is applied to the winding 62, so that the winding 62 enters a high-temperature superconducting state, thereby improving its control effect on the magnetic field effect of the current, and the heat transfer between the superconducting ring 5 and the superconducting block 6 will cause heat loss, The temperature effect of liquid nitrogen in the ring cylinder 8 is dissipated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com