A kind of painting processing electromechanical equipment

A technology of electromechanical equipment and processing boxes, applied in the direction of spraying devices, etc., can solve problems affecting the health of workers, reduce the quality of spraying paint of the device, and reduce the service life of the device, so as to avoid damage to internal components, increase the scope of spraying, and avoid paint spraying. bad face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

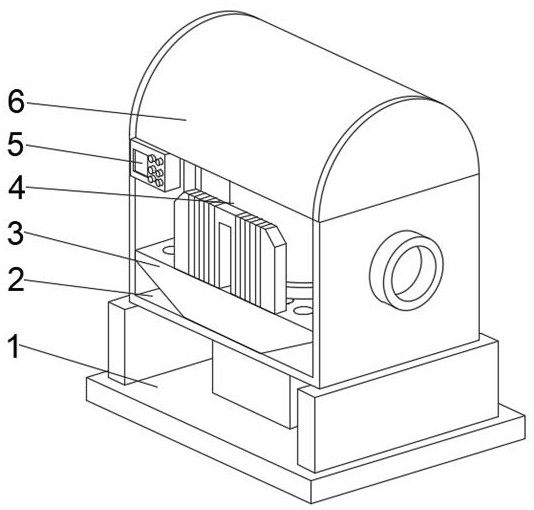

[0040] see Figure 1-6 , the present invention provides a technical solution: a painting processing electromechanical equipment, including a connection base 1, a processing box 2 is fixedly connected to both sides of the top of the connection base 1, and a collection box 3 is fixedly connected to the middle of the bottom of the inner cavity of the processing box 2 , the top middle position of the collection box 3 is provided with a spraying device 4, the front top left side of the processing box 2 is fixedly connected with a control panel 5, and the top two sides of the processing box 2 are fixedly connected with a paint storage box 6;

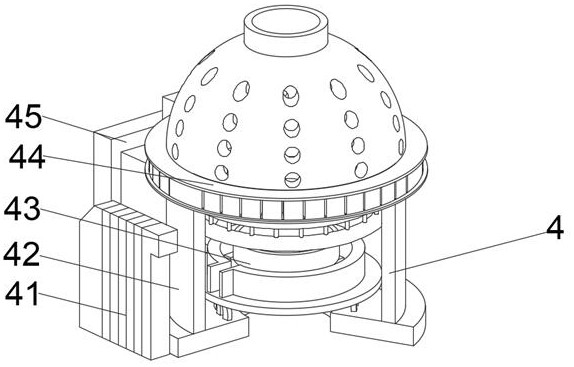

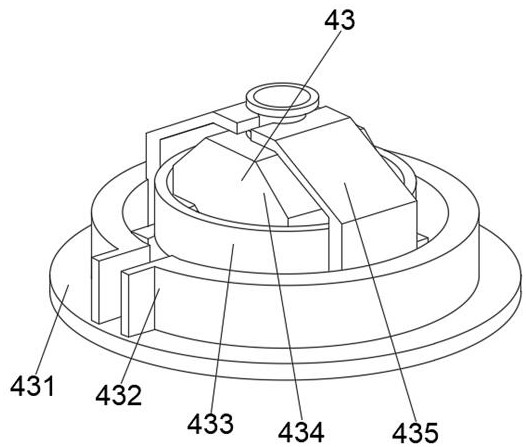

[0041] The spraying device 4 includes a placement cylinder 42, the front bottom of the placement cylinder 42 is fixedly connected with a blocking plate 41, the middle part of the outer wall of both sides of the placement cylinder 42 is connected with a paint spraying pipeline 45, and the top of the placement cylinder 42 is provided with a prote...

Embodiment 2

[0047] see Figure 1-6 , On the basis of Embodiment 1, the present invention provides a technical solution: a kind of electromechanical equipment for painting processing, including the method for using the electromechanical equipment for painting processing, step 1: install and fix the equipment, and put the paint storage box 6 is communicated with the spraying device 4, the processing box 2 is fixedly connected with the connection base 1, and the spraying device 4 is communicated with the collection box 3;

[0048] Step 2: Connect the paint spraying pipeline 45 to the placement cylinder 42, use the spray chamber generated by the auxiliary mechanism 43 and the placement cylinder 42 to spray paint on the workpiece, and connect the protective mechanism 44 to the placement cylinder 42;

[0049] Step 3: Connect the placement plate 431 with the fastening ring 432, and connect the auxiliary partition 433 with the adsorption box 434, so as to absorb the remaining residue during paint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com