Step-by-step feeding mechanism applied to continuous ejection clip applier

A technology of feeding mechanism and clamping forceps, applied in the field of medical devices, can solve the problem that the handle cannot be fired effectively, and achieve the effect of reducing the amplitude and preventing mis-clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

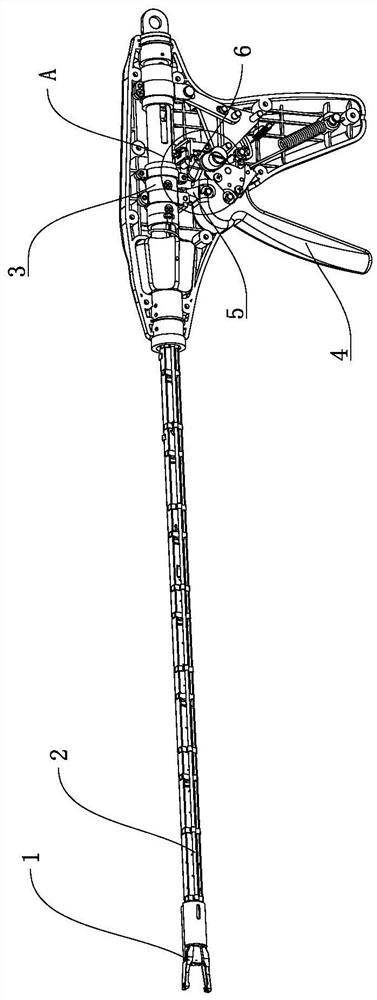

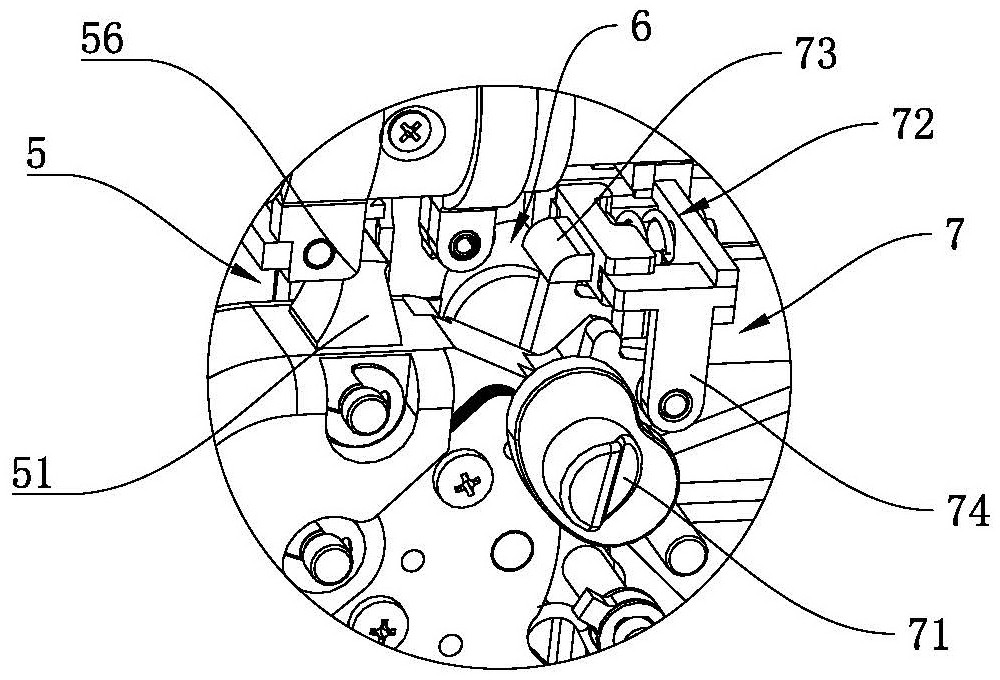

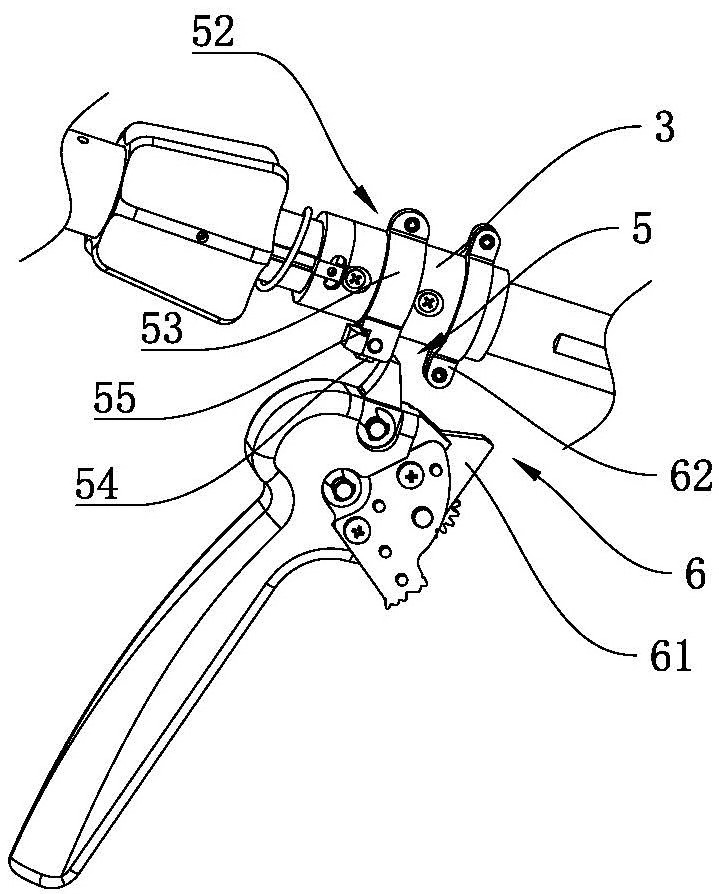

[0026] combine figure 1 and figure 2 As shown, a step-by-step feed mechanism applied to continuous clamping pliers, including a pincer head 1 and a pincer head push rod 2 connected to the pincer head 1, moving the pincer head push rod 2 can drive the pincer head 1 is opened or clamped, the pincer head push rod 2 and the pincer head 1 can be connected by the common connection method of the clamp applicator in the prior art, so as to realize the opening and closing action of the control pincer head 1. The end of the pliers head push rod 2 away from the pliers head 1 is connected with a propulsion structure 3, and a first feed mechanism 5 and a second feed mechanism 6 are also provided between the drive handle 4 and the propulsion structure 3. The drive handle 4 The first feeding mechanism 5 pushes the propelling structure 3 into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com