Probe-type electrical testing machine

An electrical measuring machine and probe-type technology, applied in the field of electrical measuring machines, can solve the problems of low detection efficiency, high detection cost, cumbersome and other problems, and achieve the effects of improving detection efficiency, improving stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

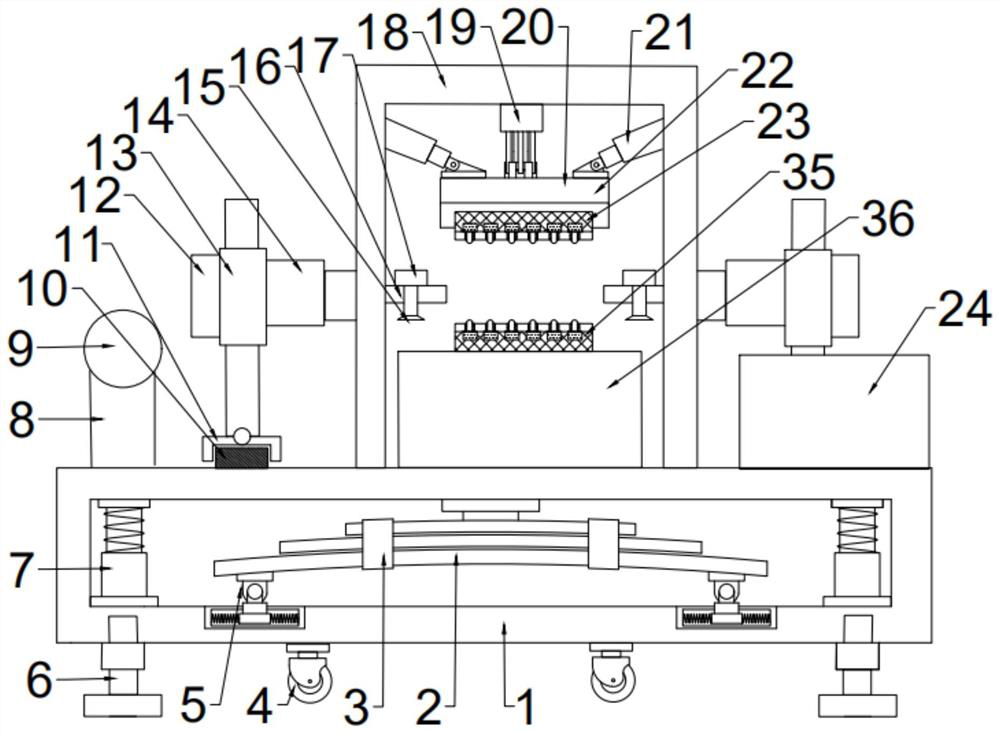

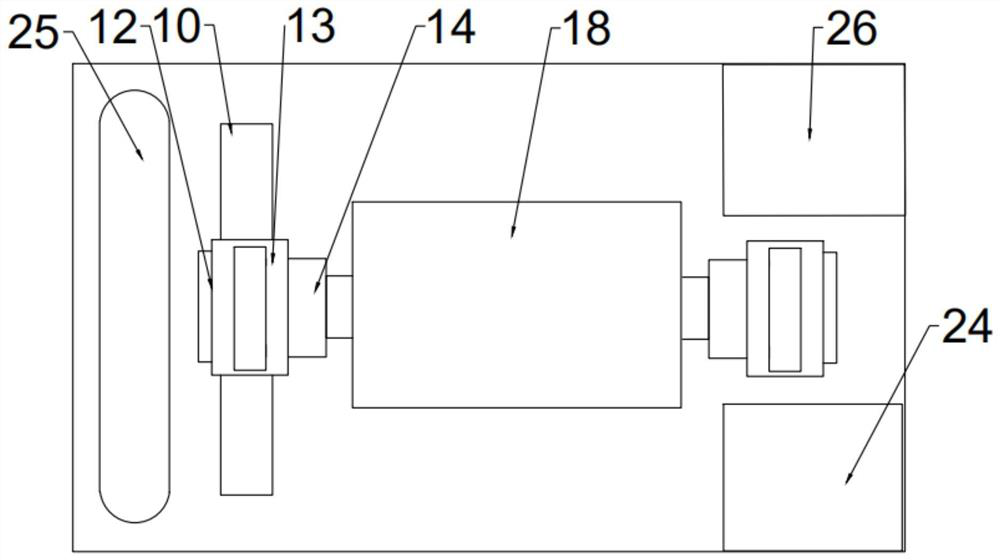

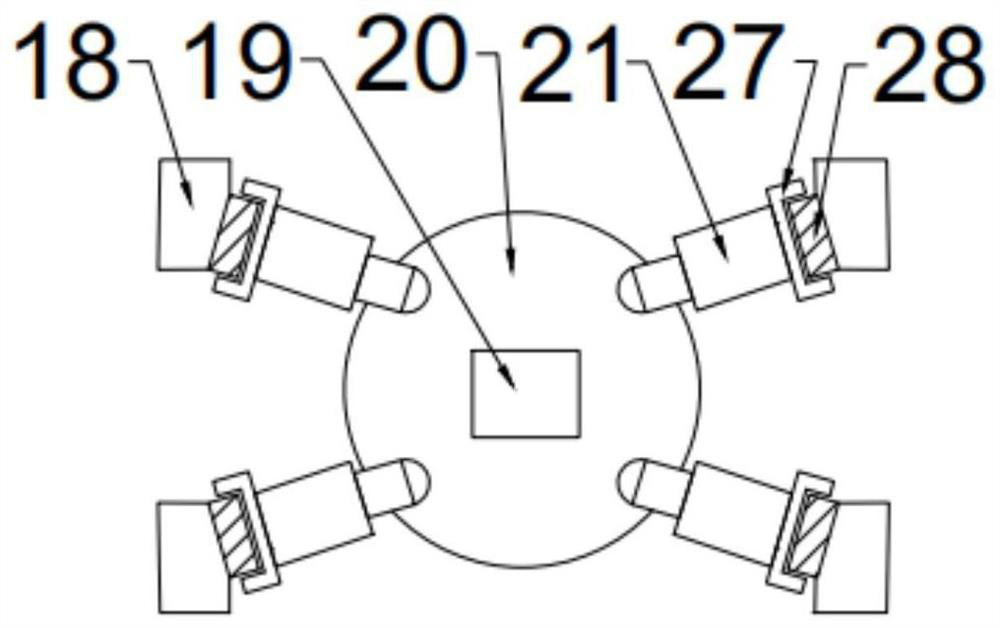

[0030] see Figure 1~5 , in an embodiment of the present invention, a probe-type electric measuring machine includes a base 1, and a product transportation device, a material retrieving device, a detection device, a feeding device and a product storage box are installed on the top of the base 1; wherein, the detection device A reclaiming device and an unloading device are respectively installed on both sides, the product transport device is located on the left side of the unloading device, and the product storage box is located on the right side of the unloading device.

[0031] The top side of the base 1 is symmetrically installed with a rotating shaft 9, and the bottom end of the rotating shaft 9 is equipped with a supporting column 8, and the end of the supporting column 8 away from the rotating shaft 9 is fixedly installed on the upper surface of the base 1, and the outer surface of the rotating shaft 9 is installed. Conveyor belt 25; the top of the base 1 is equipped with...

Embodiment 2

[0033] see Figure 1-5 , the difference between this embodiment and embodiment 1 is:

[0034] In this embodiment, a sliding structure is installed on the bottom of the base 1, and the sliding structure includes two symmetrically structured wheels 4 and fixed feet 6. The outer top of the wheel 4 is fixedly connected to the connecting plate through bolts, and the connecting plate is far away from the wheel 4. One side of the base 1 is rotatably connected with the rotating shaft, and the rotating shaft is installed on the bottom of the base 1 through the fixed block, and two fixed feet 6 of the same structure are respectively installed on both sides of the bottom of the base 1 away from the fixed block, and the fixed feet 6 are provided with There are threads, and the support height of the fixed feet 6 can be adjusted by screwing, so as to determine whether the wheels 4 are in contact with the ground, so that the entire probe-type electric measuring machine equipment can be moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com