Automatic tin ring winding tool

A tin ring and automatic technology, which is applied in the field of tin ring automatic winding tooling, can solve the problems that the solder wire cannot accurately guarantee the length, cannot meet the production and molding requirements, and is not easy to repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with embodiment.

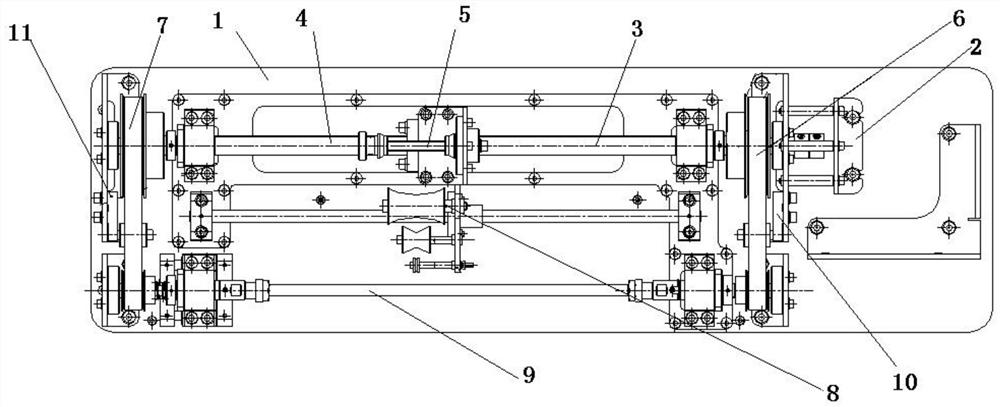

[0023] The invention provides an automatic tin ring winding tool. The tin ring is automatically wound by equipment to solve the problems of low efficiency and poor consistency of manual winding of the tin ring, and the equipment realizes the purpose of uniform winding of the tin ring and consistent inner diameter.

[0024] Work requirements for winding tooling: Solder wire winding equipment needs to be designed to evenly wind 0.38mm solder wire on the 0.8mm long mandrel 9, and the winding state should not be too tight to reduce the difficulty of cutting. At the same time, its winding length must be enough to produce more than 100 spiral solder rings at a time on the cutting equipment, and in order to ensure high production efficiency, the time required for a single equipment to run a cycle does not exceed 5 minutes. For this strict requirement, the tin ring automatic winding tool de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com