Printing head mounting device and 3D printing equipment

An installation device and 3D printing technology, applied in the field of additive manufacturing, can solve the problems of cumbersome disassembly and assembly, and high requirements for stroke processing of ball plunger modules, and achieve the effect of reducing operation difficulty, simplifying positioning and distance, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

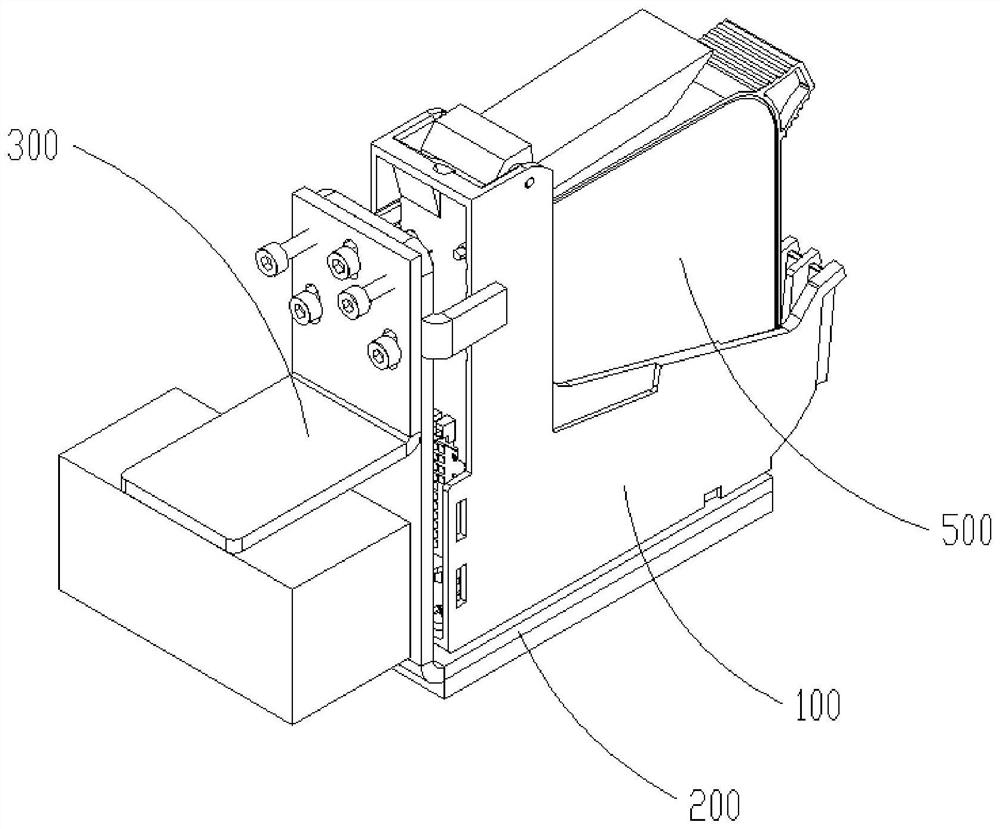

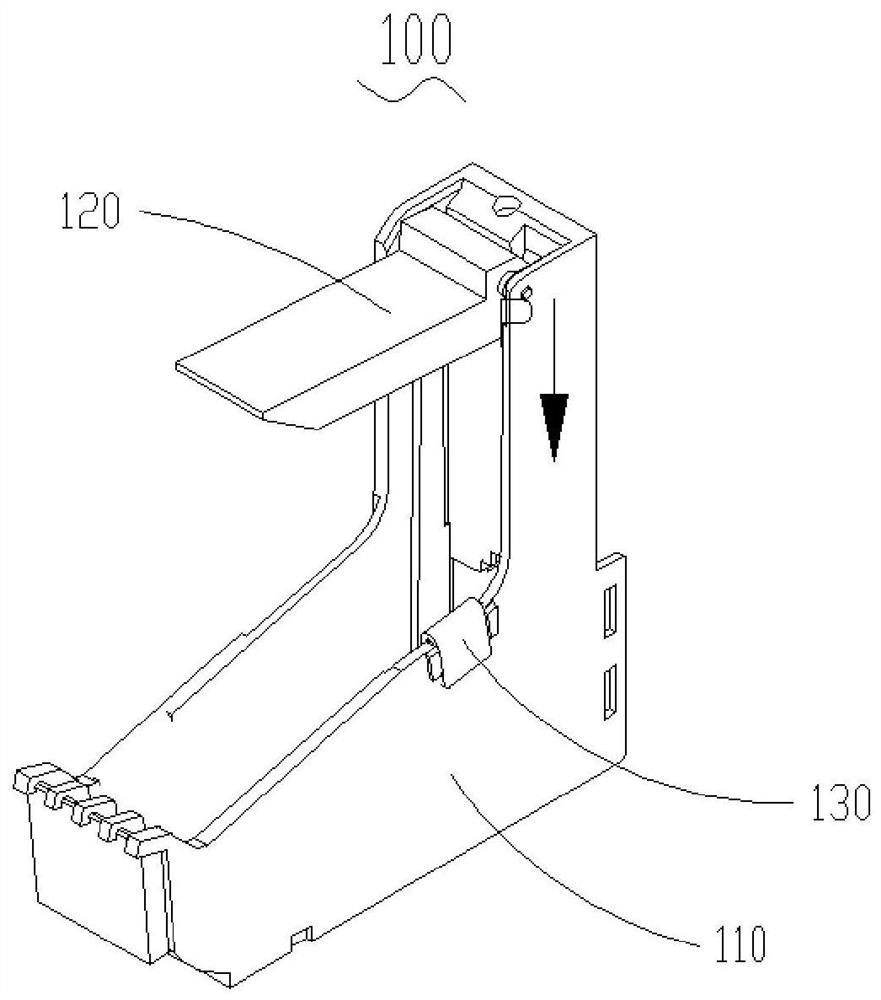

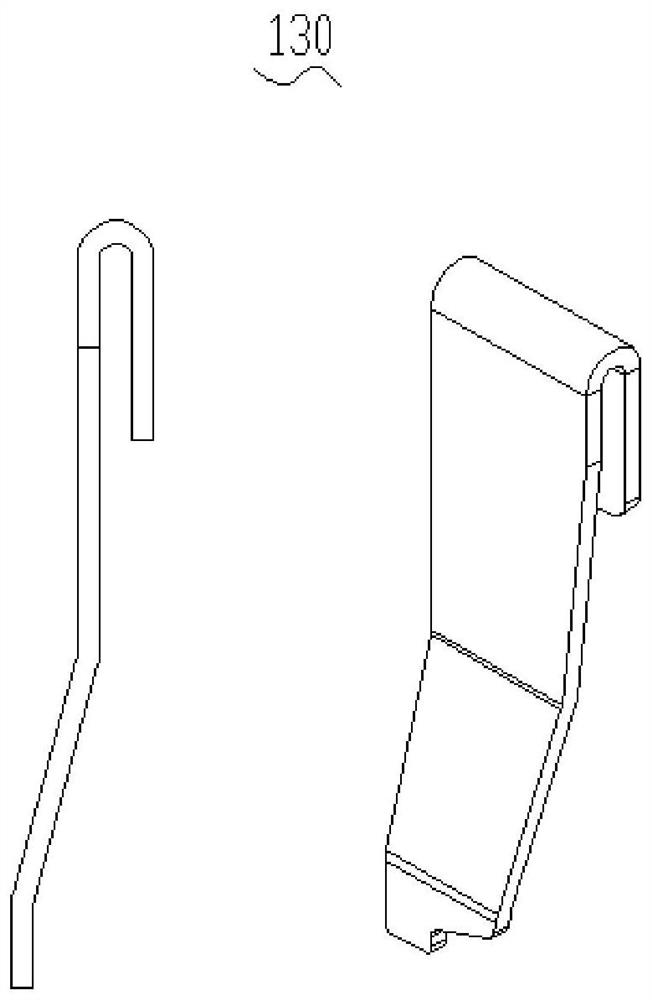

[0028] Such as Figure 1 to Figure 4 As shown, it is an installation device of a print head 500, the installation device includes a frame base assembly 100, a connection assembly 200 and an adjustment assembly 300; the frame base assembly 100 is seated on the connection assembly 200, And the two are fixed by bolts; one end of the adjustment assembly 300 is connected with the connection assembly 200 through bolts, and the other end of the adjustment assembly 300 is connected with the driving mechanism in the print head 500 assembly. The frame-type base assembly 100 includes a frame-type fixing base 110, the frame-type fixing base 110 is a cuboid structure with a certain open surface, and the inner space of the cuboid structure is the accommodating space of the print head 500, which is used to hold Support and position printing head 500, and be provided with window at the bottom of described frame type fixed seat 110, described window is used for printing head 500 ejection outle...

Embodiment 2

[0033] like Figure 5 to Figure 7 As shown, it is a schematic diagram of the structure of the board-type base assembly in use. The board-type base assembly 400 includes a board-type fixing seat 410 and a board-type pressing plate 420. The plate-type base assembly 400 of the head 500 space. The plate-shaped fixing seat 410 is provided with a first positioning structure 411 and a second positioning structure 412 for supporting and positioning the print head 500. The first positioning structure 411 is used to support the print head 500, so that the printing There is a certain distance between the head 500 and the powder-spreading surface to support the print head 500, that is, the print head 500 is located on the first positioning structure 411; the second positioning structure 412 is a stepped structure, with The printing head 500 can be stably placed in the plate-shaped fixing seat 410 to form a fastening force and a supporting force in a direction opposite to the first positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com