Aluminum alloy double-layer CRH train body structure and CRH train

A car body structure and EMU technology, which is applied to railway car bodies, railway car body parts, transport passenger cars, etc., can solve the problems that the number of passengers cannot meet the demand and the accommodation space is small, and achieve high section profile and large accommodation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

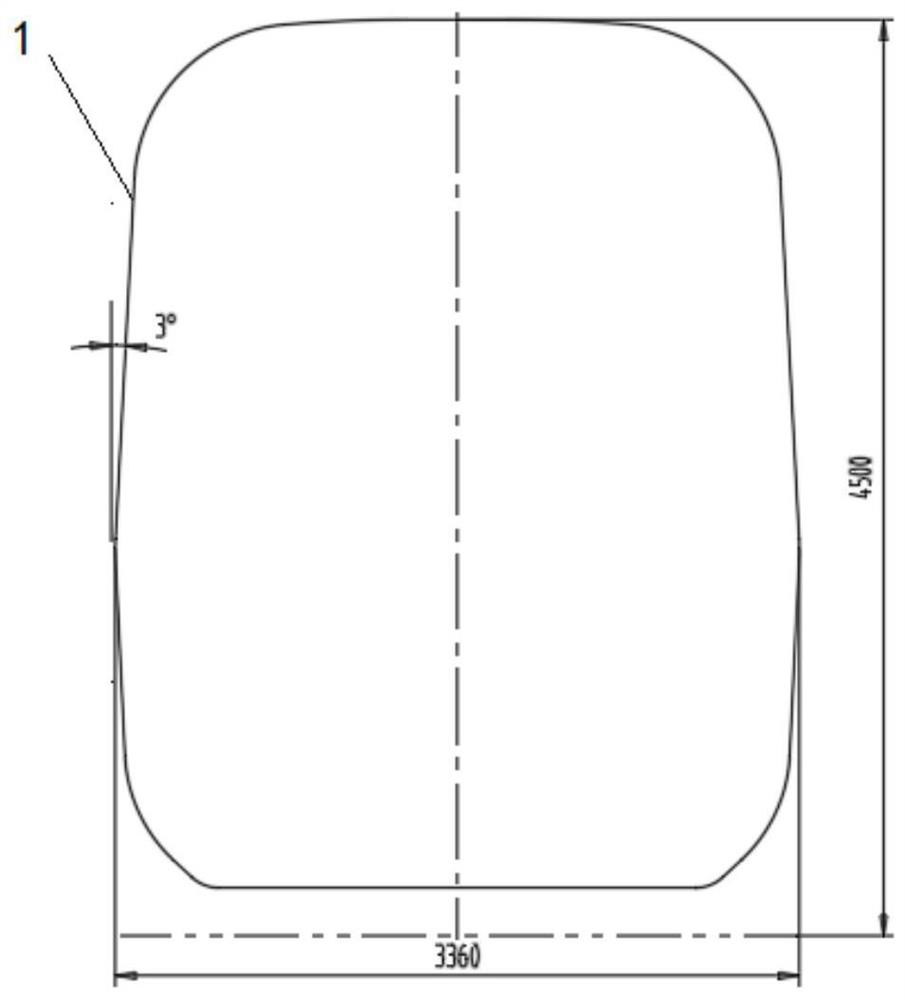

[0041] refer to figure 1 , the overall section of the car body adopts a conventional drum-shaped profile, that is, the drum-shaped section profile structure that maintains the outer profile as a combination of straight lines and arcs ensures that the vehicle has good aerodynamic performance, and at the same time takes into account the manufacturability of the vehicle. The outer profile of the car body section is increased to 4500mm. On the premise of ensuring that the car body width remains unchanged at 3360mm, the inclination angle of the side wall 1 is adjusted to 3° to widen the upper part of the car body section. Make the upper storage space of the car body wider.

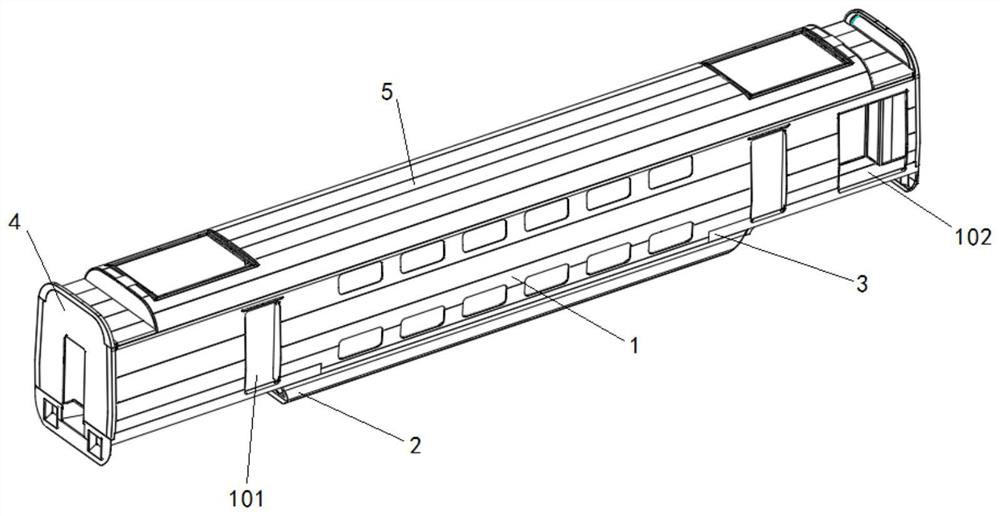

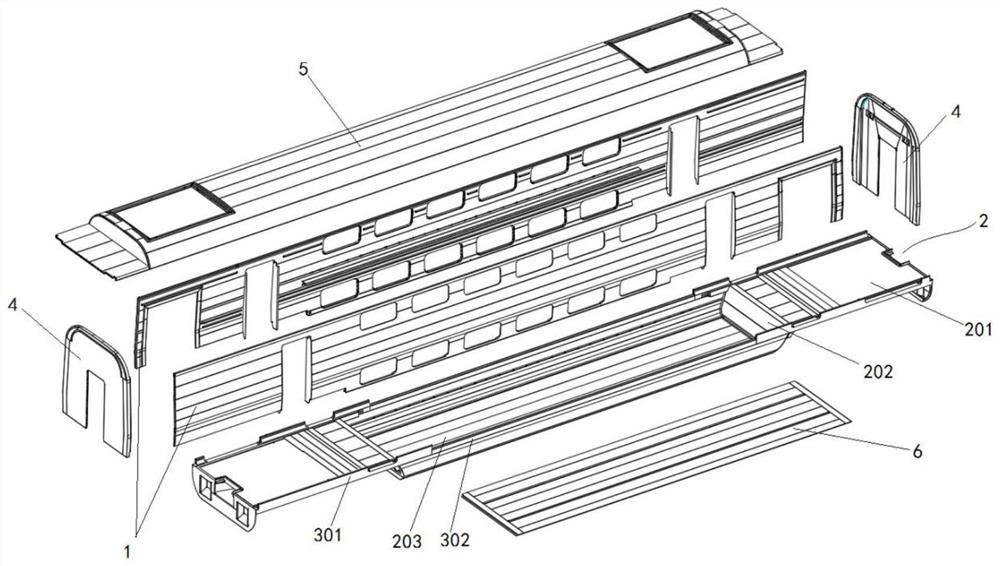

[0042] In order to realize the connection and installation between the end area of the car body and the bogie, as well as the convenience for passengers to pedal from the end of the vehicle to enter the car, the end area of the car body is still maintained as a single-layer car body structure; The central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com