Mine steel wire rope dust and dirt removing robot and working method

A steel wire rope and robot technology, applied in the field of dust removal robots, can solve the problems of low dust removal efficiency of steel wire ropes, affecting the detection results of steel wire ropes, major hidden dangers of mine safety, etc., to prevent motor jamming, save manpower, and high cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] specific implementation plan

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

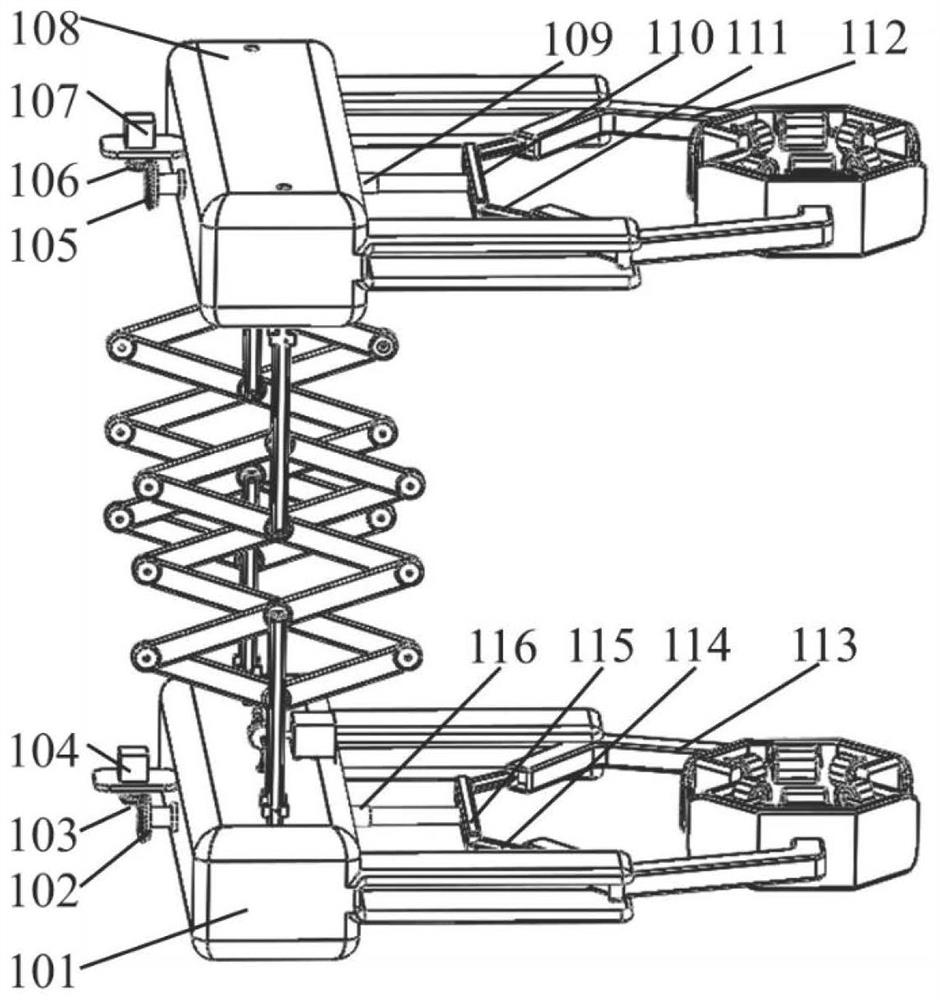

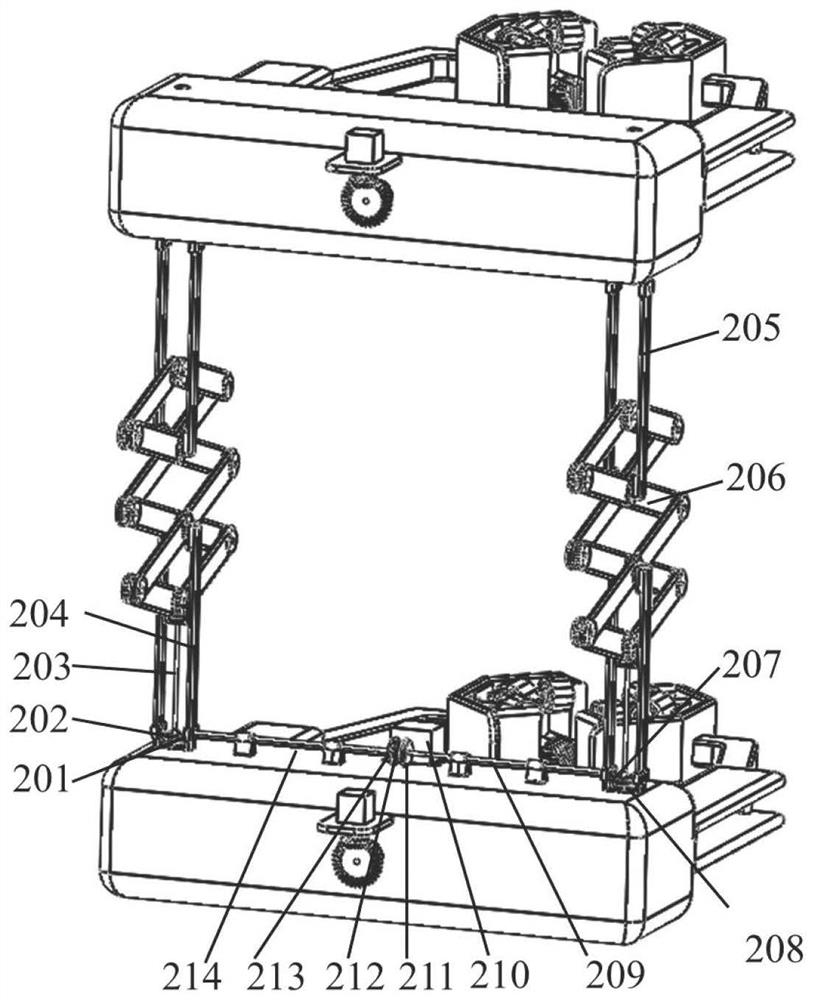

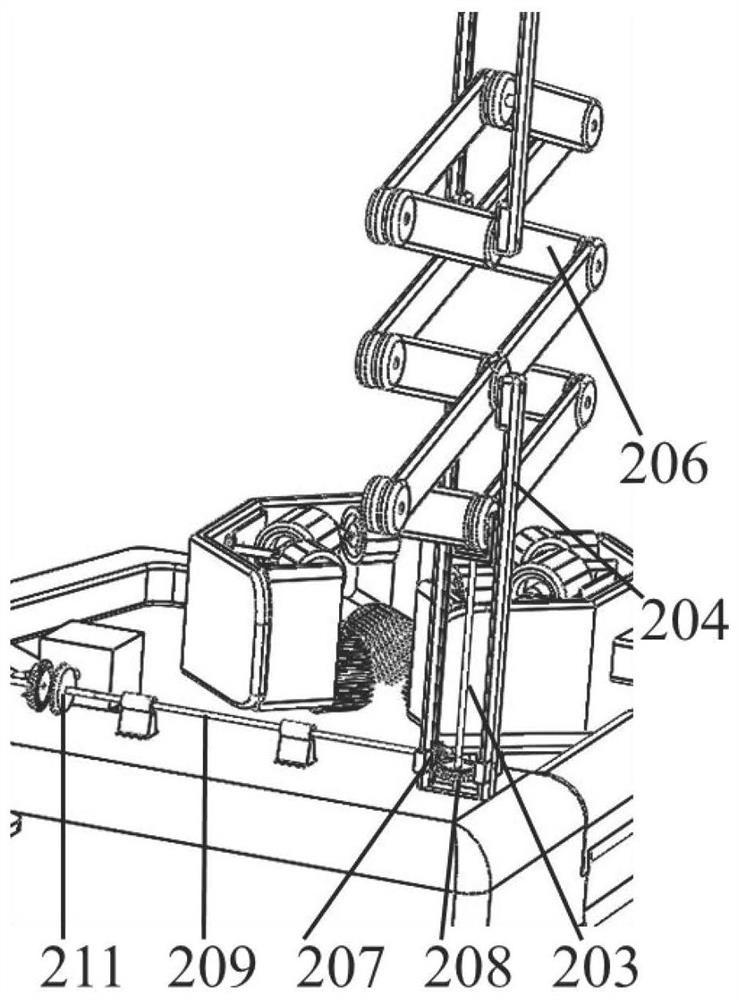

[0043] Such as figure 1 , Figure 9 with Figure 10 As shown, a mine steel wire rope dust removal robot and its use method meet the requirements of climbing and dust removal for mine steel wire ropes, and can realize efficient and non-destructive dust removal for steel wire ropes. The invention discloses a mine steel wire rope dust removal robot, which includes a tightening device, a lifting device, a dust removal device and a driving device; The upper clamp 112 for clamping the mine steel wire rope, and the lower clamping device is provided with the lower clamp 113 for clamping the mine steel wire rope. Through the cooperation of the upper and lower clamping devices, the robot can hold the steel wire rope tightly; Between the lower holding devices, when working, adjust the distance between the upper holding device and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com