Chip and wafer cutting method for improving silver colloid climbing in welding process

A technology of welding process and cutting method, which is applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of high product scrap rate, reduce scrap rate, improve silver glue climbing, and improve product reliability and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A wafer cutting method for improving the climbing of silver glue during chip welding, comprising the following steps:

[0051] Step S1, wafer cutting preparation: after receiving the wafer to be cut, first check whether there is a film on the back of the incoming wafer. If there is no film, a film needs to be applied to the back of the wafer. If there is a film, you need to check whether the back film has expired. If the film on the back has expired, it will need to be replaced with an unexpired film.

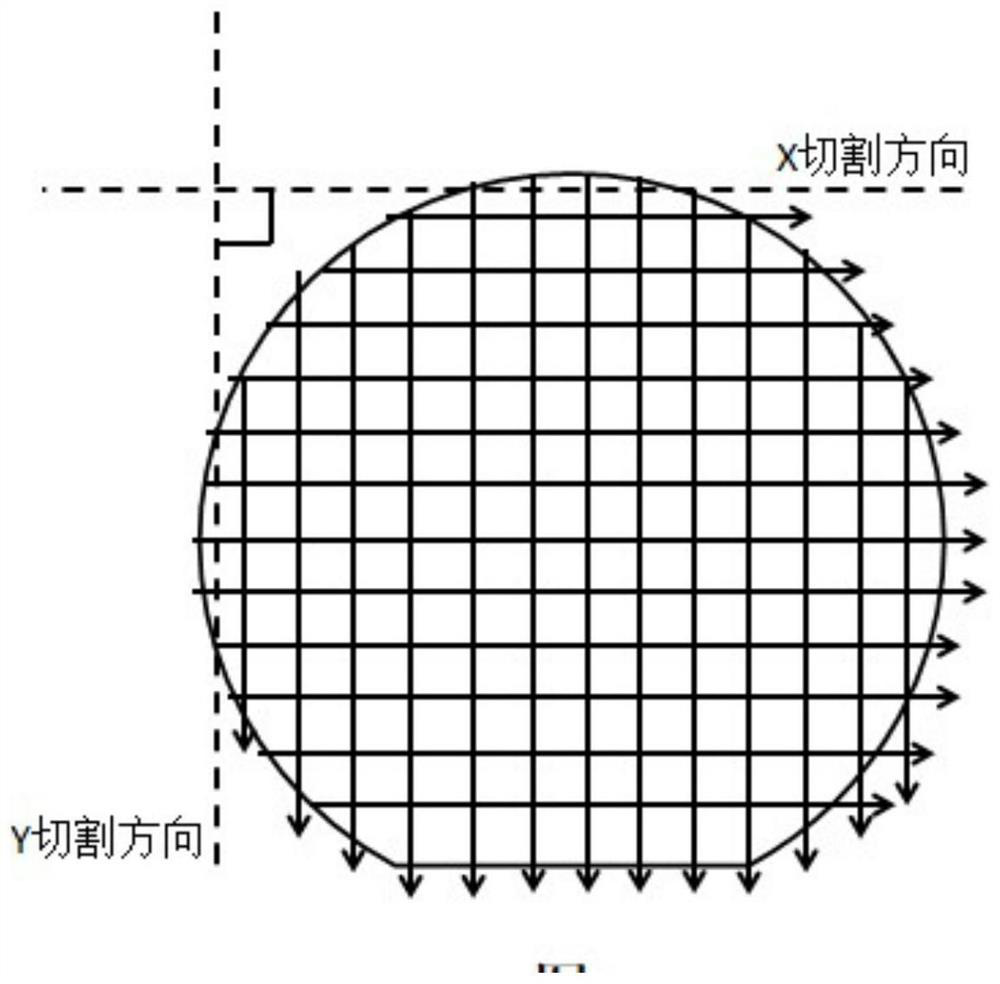

[0052] Step S2, wafer cutting: combining figure 1 As shown, when a wafer is prepared for various cutting tasks, the blade 1 with a wider knife mark is selected, which is used for the initial cutting of each cutting line of the wafer. The width of the knife mark is W1, the cutting thickness is set to Z1, and then the grooving cutting of each dicing lane in the X direction is started.

[0053] When the blade 1 steps to the Nth cutting lane in the X direction, the syste...

Embodiment 2

[0068] A wafer cutting method for improving the climbing of silver glue during chip welding, comprising the following steps:

[0069] Step S1, wafer cutting preparation: After receiving the wafer to be cut, first check whether there is a film on the back of the incoming wafer. If there is no film, the film needs to be applied to the back of the wafer. If there is a film, you need to check whether the back film has expired. If the film on the back has expired, it will need to be replaced with an unexpired film.

[0070] Step S2, wafer cutting: combining figure 1 As shown, when a wafer is prepared for various cutting tasks, the blade 1 with a wider knife mark is selected, which is used for the initial cutting of each cutting line of the wafer. The width of the knife mark is W1, the cutting thickness is set to Z1, and then the grooving cutting of each cutting lane in the X direction is started.

[0071] When the blade 1 steps to the Nth cutting lane in the X direction, the sy...

Embodiment 3

[0086] A wafer cutting method for improving the climbing of silver glue during chip welding, comprising the following steps:

[0087] Step S1, wafer cutting preparation: After receiving the wafer to be cut, first check whether there is a film on the back of the incoming wafer. If there is no film, the film needs to be applied to the back of the wafer. If there is a film, you need to check whether the back film has expired. If the film on the back has expired, it will need to be replaced with an unexpired film.

[0088] Step S2, wafer cutting: combining figure 1 As shown, when a wafer is prepared for various cutting tasks, the blade 1 with a wider knife mark is selected, which is used for the initial cutting of each cutting line of the wafer. The width of the knife mark is W1, the cutting thickness is set to Z1, and then the grooving cutting of each cutting lane in the X direction is started.

[0089] When the blade 1 steps to the Nth cutting lane in the X direction, the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com