Efficient low-energy-consumption four-stroke opposed piston engine

A technology of opposed pistons and four strokes, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of incomplete closure of valves, unequal lateral force, unequal cylinder pressure, etc., to optimize engine design, reduce The effect of overall structure and high lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

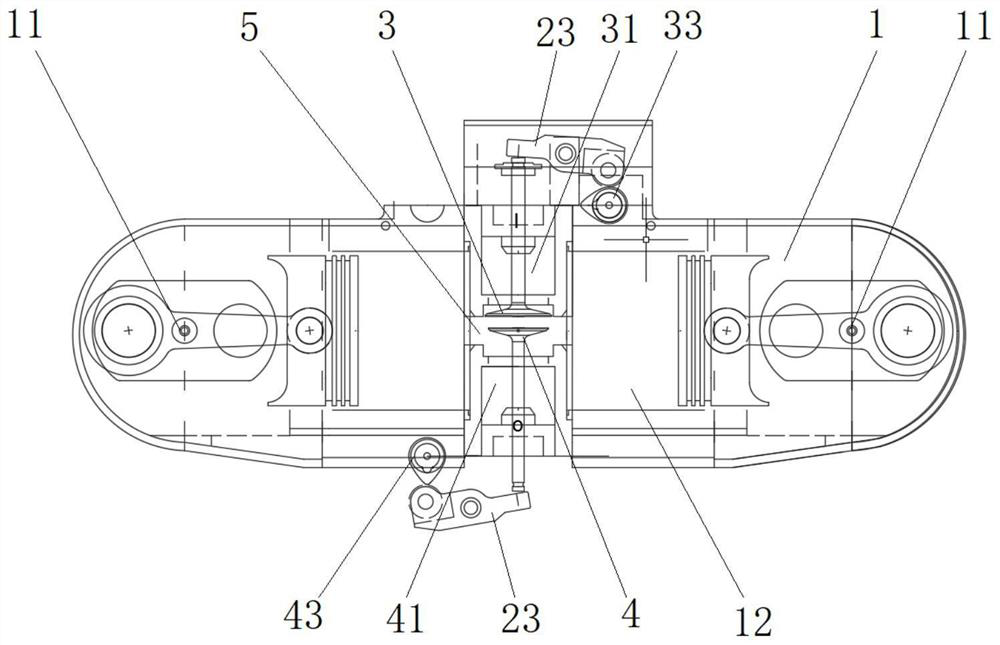

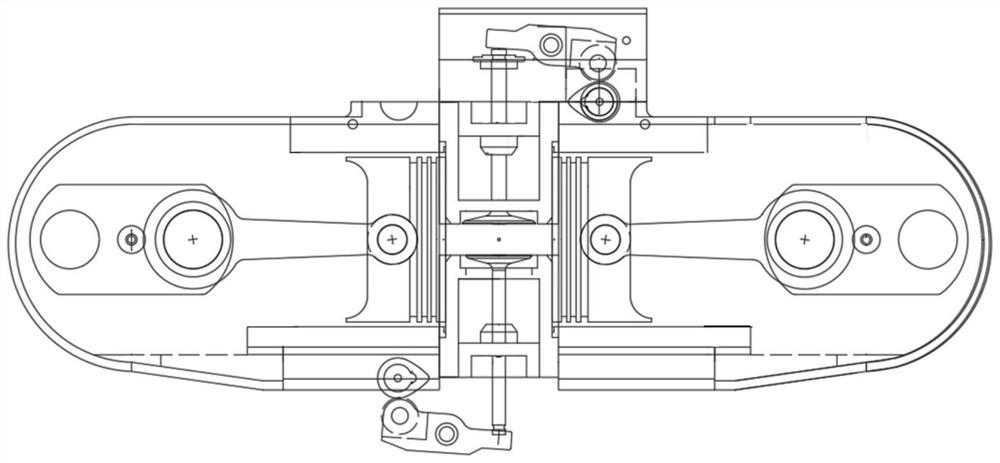

[0022] Example 1: An Efficient low-power four-stroke opposed piston engine, comprising two opposed pistons and the cylinder 1, a combustion chamber disposed between the two pistons and cylinders 1 5, two pistons and the cylinder 1 with respect to symmetrically distributed type combustion chamber 5, the combustion chamber 5 of the intake valve 3 and exhaust valve 4 are disposed vertically opposed, inlet and outlet valves 4 is a conventional valve structure, the intake valve 3 and exhaust valve 4 respectively connected to a respective cam mechanism implemented alternately opening and closing, the cam mechanism with the respective rotary shaft 1 and the cylinder piston 11 is connected, through the cam gear such that movement of the piston controlling the intake valve 3 and exhaust valve 4 to open with one another closing motion to achieve four-stroke cylinder. Intake valve 3 of the present invention, the exhaust valve 4 may be set to a plurality of sets. When the intake valve 3 and e...

Embodiment 2

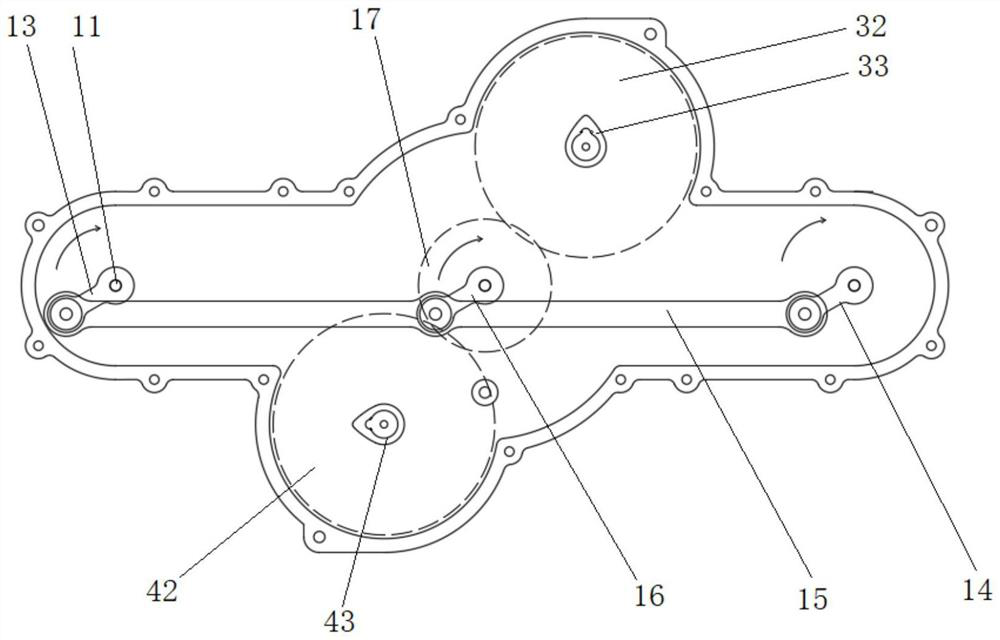

[0025] On the basis of the embodiment 1, when the transmission mechanism is a cam gear, a first crank mechanism connecting rod 13, a second crank mechanism 14 are replaced by a first link, and a third gear Eren, four the interlocking gear 15 and drive the third link bar 16 is replaced with a center gear 17 fixed coaxially with the opposed interlocking gear 171, a first intermediate gear 18, fourth intermediate gear 21, respectively, and the counter the piston rod 11 at both ends of the interlocking shaft is mounted, a first intermediate gear 18, fourth intermediate gear 21 are connected through the second gear 19, the third interlocking gear 20 coaxially with the movable contact from both sides of the teeth in opposing interlocking gear 171, gear drive overall configuration. Center gear 17 and intake camshaft gear 32, the gear teeth ratio of the exhaust camshaft 42 between the intake cam 33 and an exhaust cam 43 can be arranged in the direction of arrangement of the actual transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com