Thermal management device

A heat management, pipe body technology, applied in the field of heat management, to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

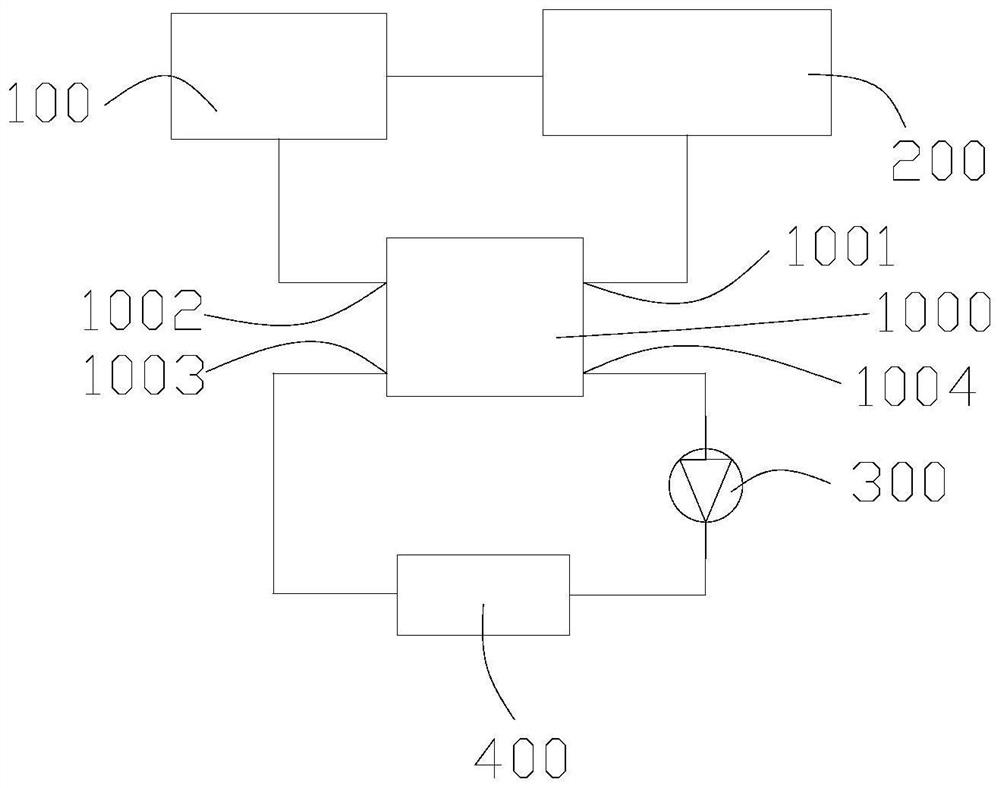

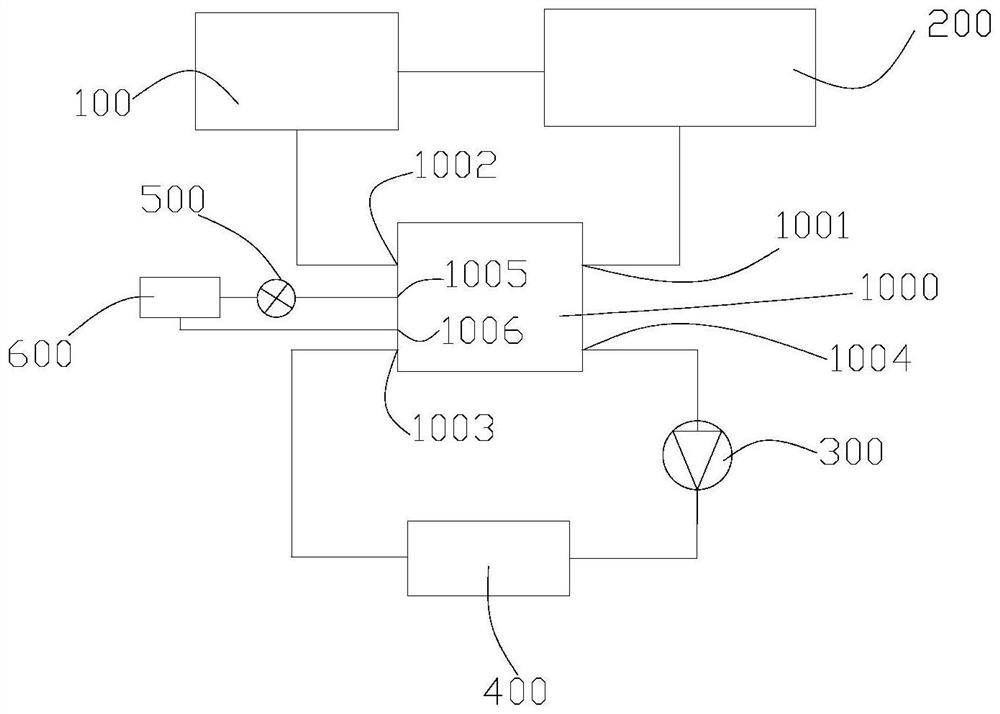

[0025] The thermal management system and the thermal management device of the technical solution of the present invention can have multiple implementations, at least one of which can be applied to a vehicle thermal management system, and at least one implementation can be applied to a household thermal management system or a commercial thermal management system, etc. For other thermal management systems, the vehicle thermal management device is taken as an example below to illustrate with reference to the accompanying drawings.

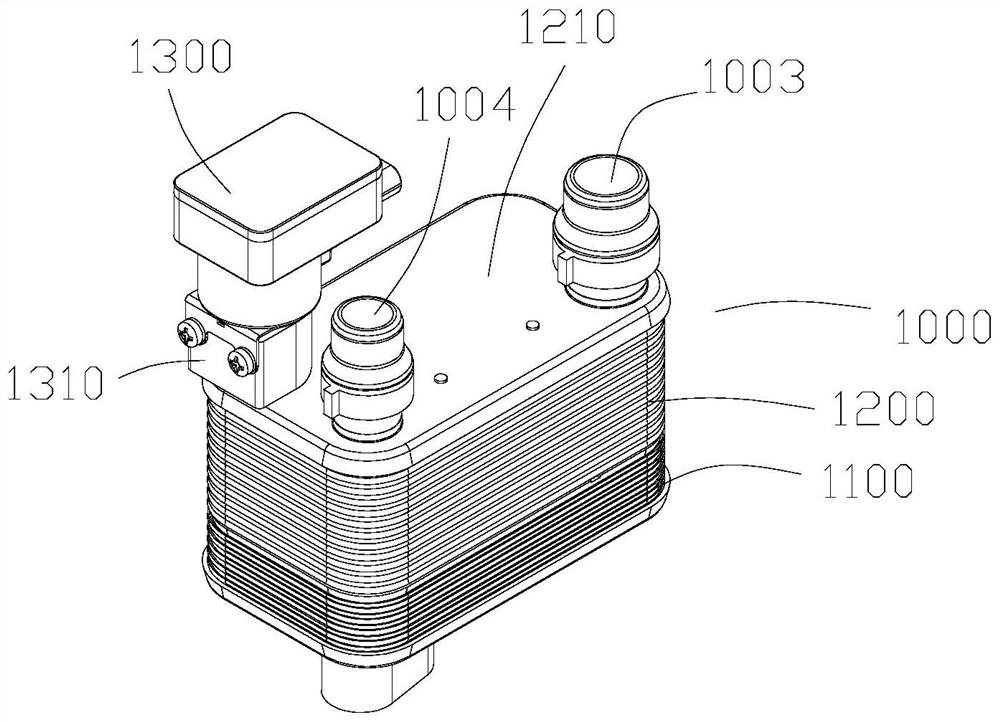

[0026] see Figure 3-11 . The heat management device 1000 includes a heat exchange core and a throttling unit 1300. The heat exchange core includes a first plate body 1140 and a second plate body 1210, and along the stacking direction of the plates, the first plate body 1140 and the second plate body 1210 between a plurality of stacked plates. In some embodiments, the heat exchange core includes a first heat exchange part 1100, a connecting plate bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com