Busbar structure for capacitor

A technology for busbars and capacitors, which is applied in the direction of wire-wound capacitors, fixed capacitor parts, fixed capacitor leads, etc., which can solve problems such as vibration resistance obstacles, drop-off position accuracy, and deterioration, so as to improve vibration resistance and suppress resonance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

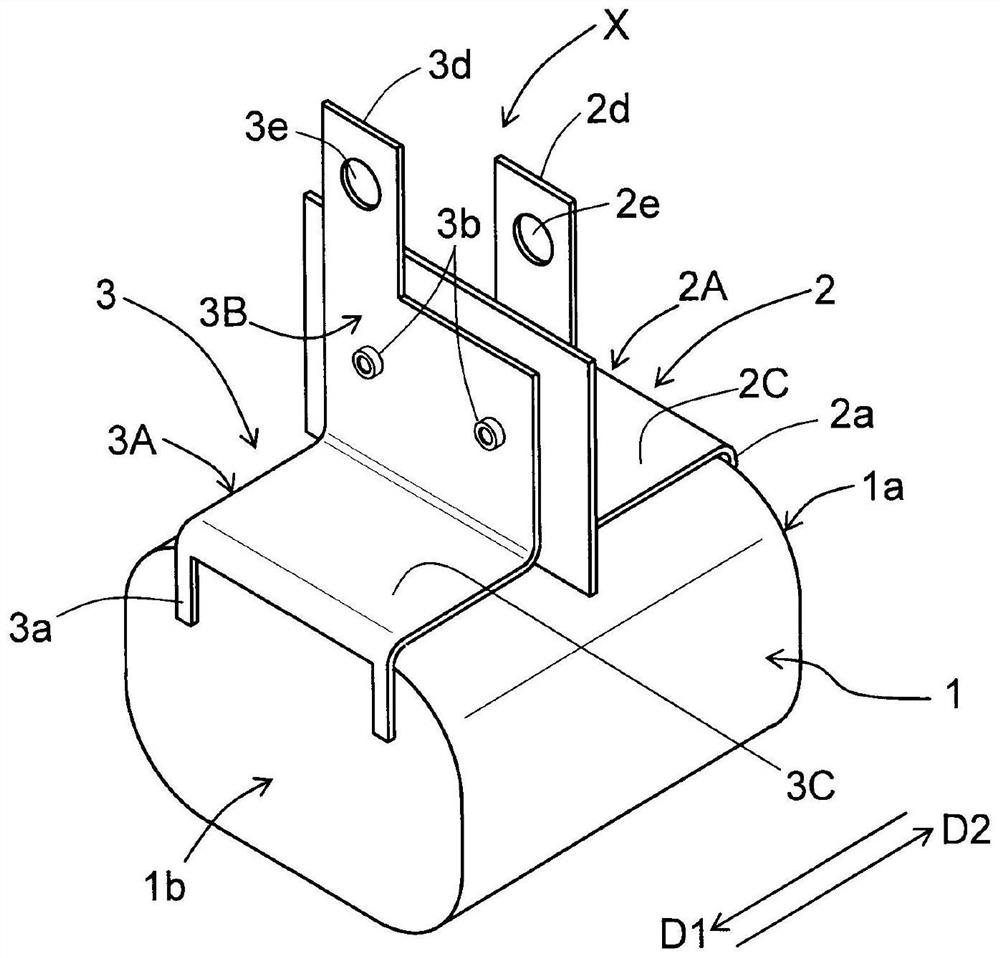

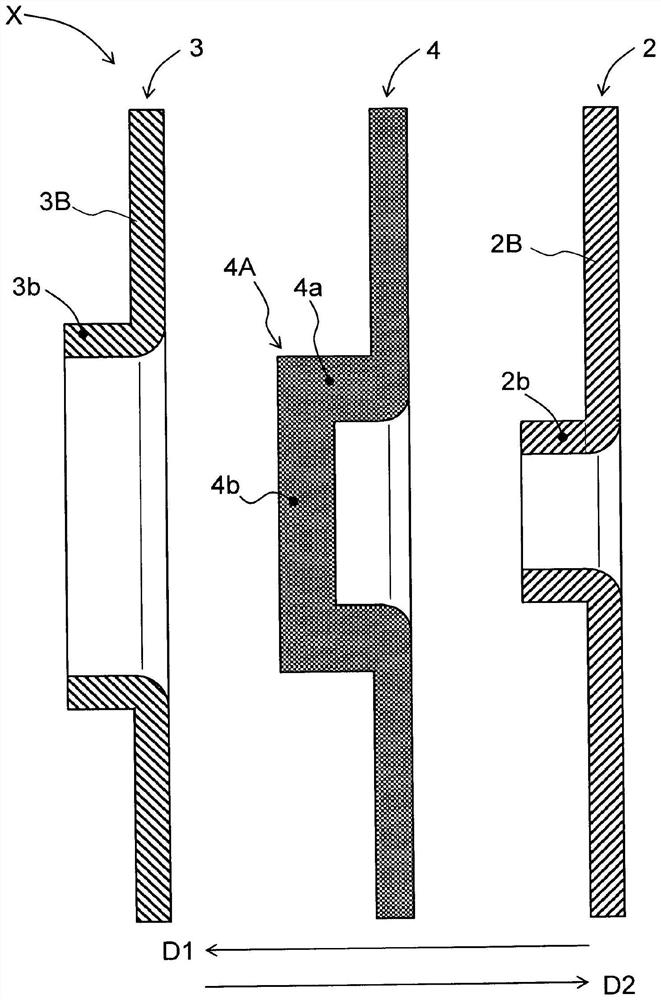

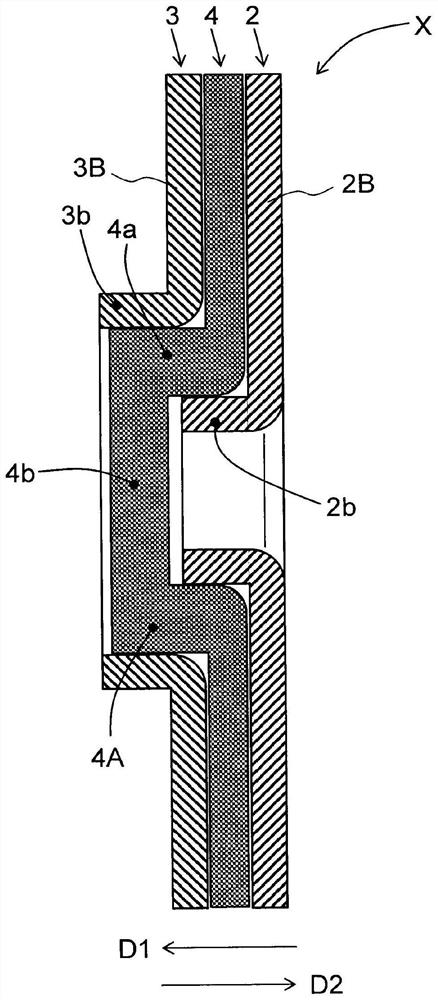

[0043] exist figure 1 ˉ image 3Among them, 1 is the capacitor element, 1a, 1b are the electrodes of the first polarity and the second polarity at both axial ends of the capacitor element 1, 2 is the first bus bar, 3 is the second bus bar, 2A is the first The first main body plate part in the bus bar 2, 3A is the second main body plate part in the second bus bar 3, 2B is the first opposite plate part, and 3b is the second opposite plate part. The main body plate portions 2A, 3A have an L-shaped bent shape, and the opposing plate portions 2B, 3B are part of the main body plate portions 2A, 3A. 2b is the first fitting portion (flange portion) in the first opposing plate portion 2B, 3B is the second fitting portion (burring portion) in the second opposing plate portion 3B, 4 is an insulating plate, and 4A is an insulating plate. The bulge in plate 4 (in figure 2 and image 3 The middle is the cylindrical part with a cover), D1 is the first direction, and D2 is the second dir...

no. 2 example

[0058] In the second embodiment involved Figure 5 and Figure 6 middle, 3b 1 is the conical part in the second fitting part 3b, 3b 2 For the top plate part, 3b 3 is a cylindrical part, 4A' is a bulging part in the insulating plate 4, 4c is an annular part in the bulging part 4A', 4c 1 is an annular recess, 4d is a bottomed recess, and 4e is a peripheral wall part. Other structures are the same as those of the first embodiment. exist Figure 5 and Figure 6 , and in the first embodiment the figure 1 ˉ image 3 The same reference numerals used in 1 and 2 refer to the same structural elements, and detailed description thereof will be omitted.

[0059] In the above-mentioned first embodiment, the first fitting portion 2b in the first opposing plate portion 2B is fitted into the bulging portion 4A in the insulating plate 4 and the second fitting portion 3b in the second opposing plate portion 3B is fitted in the insulating plate 4. A structure in which the bulging portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com