Adjustable grinding device for oil cylinder barrel machining

An adjustable, oil-cylinder technology, used in grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc. Quick adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

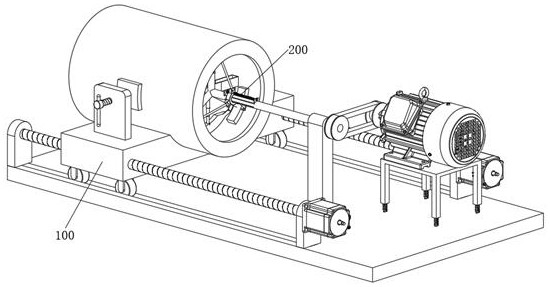

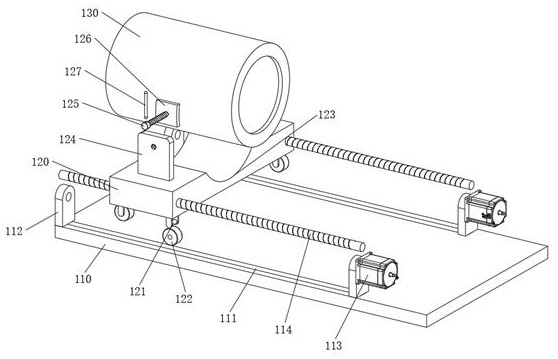

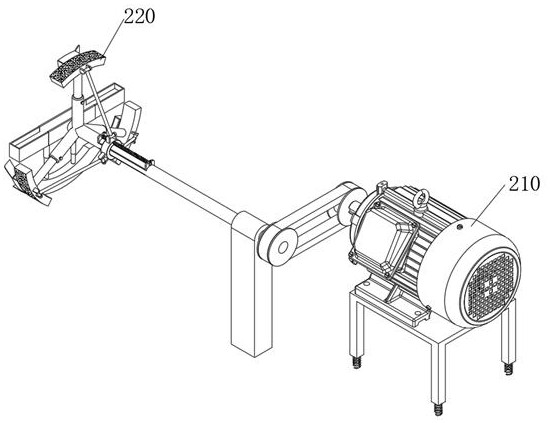

[0050] see Figure 1-Figure 5 As shown, an adjustable grinding device for cylinder barrel processing is provided, including a fixing device 100 and a collecting device 200 arranged above the fixing device 100, the fixing device 100 includes a fixing table 110 and a connecting table 120, and the surface of the fixing table 110 There are chute 111 on both sides, and the surface of the fixed platform 110 is located at the two ends of the chute 111 and fixedly connected with the fixed plate 112, and the side wall of one of the fixed plate 112 is equipped with the first motor 113, and the output shaft of the first motor 113 passes through The fixed plate 112 is also connected with a screw mandrel 114, the two ends of the screw mandrel 114 are rotationally connected with the fixed plate 112, the screw mandrel 114 passes through the connecting platform 120 and is threadedly connected with it, the bottom of the connecting platform 120 is provided with a plurality of connecting frames 121...

Embodiment 2

[0059] In order to improve the cleaning effect to debris, the following improvements are made on the basis of Example 1:

[0060] see Figure 6 As shown, wherein, the bottom of the telescopic rod 217 is provided with a connecting plate 240, the bottom outer wall of the connecting plate 240 is attached to the bottom inner wall of the oil cylinder body 130, and a scraper 241 is connected to the opening of the scraper 226, and the scraper 241 is inclined. Setting, one end of the scraper 241 is attached to the side wall of the connecting plate 240, the transmission shaft 213 drives the collecting part 216 to move, the threaded rod 261 drives the connecting plate 240 to move through the telescopic rod 217, and the moving of the connecting plate 240 moves the inner wall of the cylinder body 130 bottom. The debris pushes, at this time, the scraper 226 rotates to drive the scraper 241 , and the scraper 241 rotates to scrape off the debris at the side wall of the connecting plate 240 ....

Embodiment 3

[0062] In order to realize the adjustment of the size of the collector 216, the following improvements are made on the basis of Embodiment 1:

[0063] see Figure 7 As shown, wherein, the collector 216 includes a housing 250 and a mounting plate 251, and the two ends of the housing 250 are provided with a sliding cavity 252, and the mounting plate 251 slides in the sliding cavity 252, when the smaller oil cylinder body 130 is When in use, the mounting plates 251 at both ends are pushed into the housing 250 to realize the adjustment of the collector 216 so as to maximize the collection effect in the oil cylinder body 130 of different sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com