Plywood compacting device

A compacting device and a technology for plywood, applied in the field of sheet metal processing, can solve problems such as plywood offset, and achieve the effect of avoiding offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

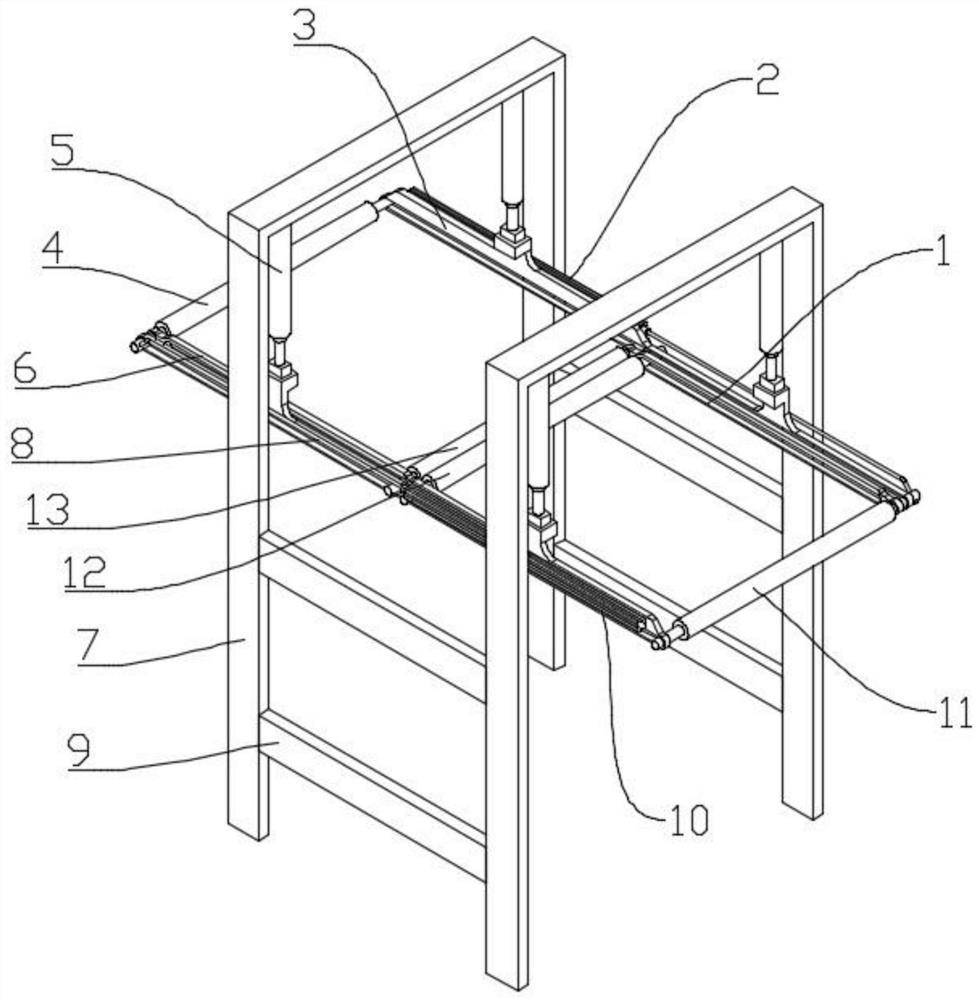

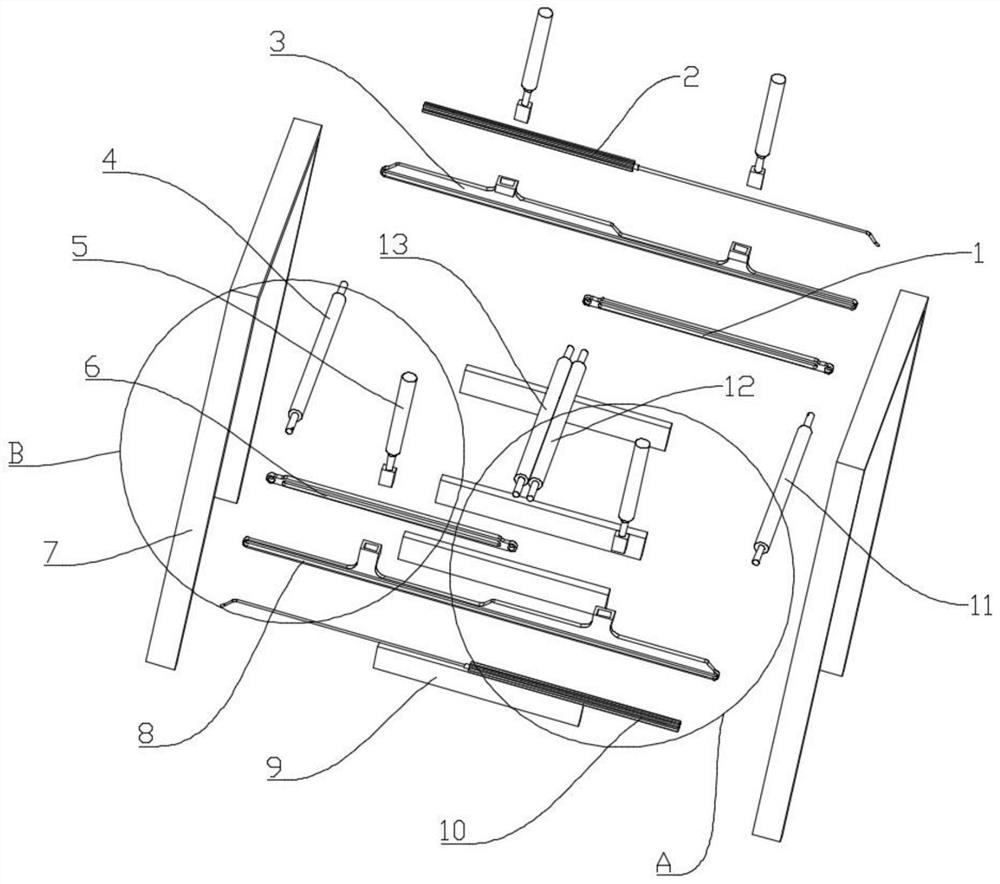

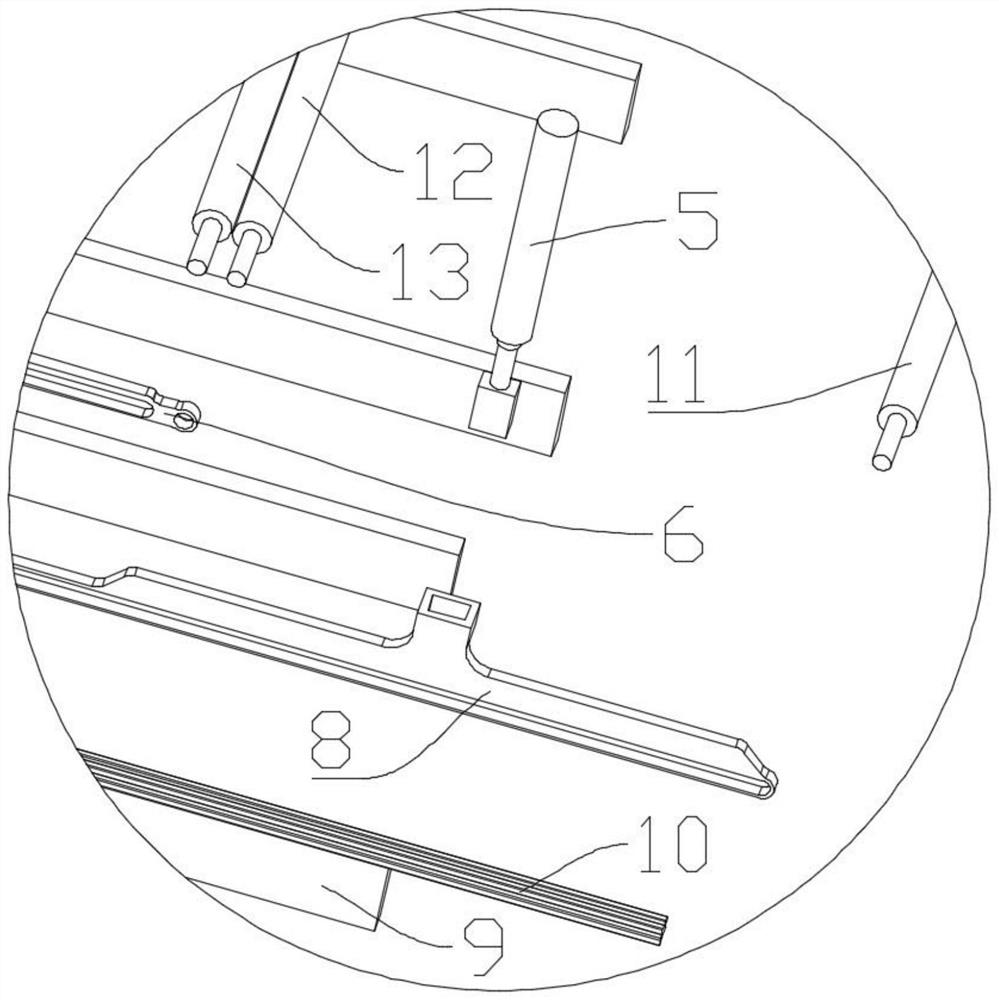

[0020] like Figure 1 ~ Figure 4 As shown, a plywood compacting device includes a first short guide rail 1, a first electric push rod 2, a first long guide rail 3, a first moving roller 4, a hydraulic rod 5, a second short guide rail 6, a bracket 7, a first Two long guide rails 8, the second electric push rod 10, the fourth moving roller 11, the third moving roller 12, the third moving roller 13 and several reinforcing plates 9,

[0021] The first short guide rail 1, the second short guide rail 6, the first long guide rail 3 and the second long guide rail 8 are all provided with slide grooves;

[0022] The first moving roller 4, the third moving roller 13, the third moving roller 12, the fourth moving roller 11, the first short guide rail 1, the second short guide rail 6, the The first long guide rail 3 and the second long guide rail 8 are all arranged on the same horizontal plane, and the first moving roller 4, the third moving roller 13, the third moving roller 12 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com