LED lighting module

A technology of LED lighting and LED light board, which is applied in the field of LED lighting, can solve problems such as low production efficiency, lower protection level, and inability to move modules, and achieve the effects of improving production efficiency, reducing impact, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

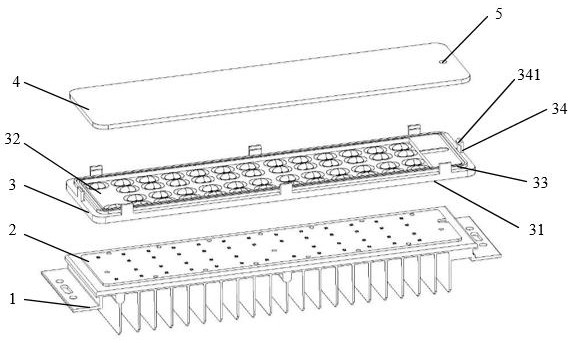

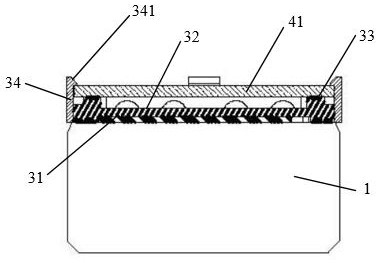

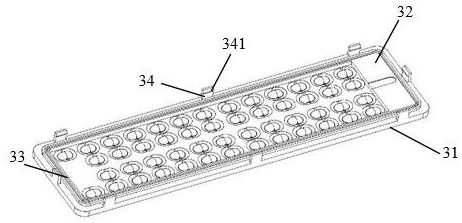

[0027] Please refer to the attached Figures 1 to 3 , an LED lighting module, including a heat sink 1, an LED lamp board 2, a lens cover 3 and a protective glass 4, the lens cover 3 has an inner surface 31 close to the LED lamp board 2 and close to the protective glass 4 The outer surface 32 of the glass 4 .

[0028] Further, the protective glass 4 is flat glass 41 .

[0029] Further, the inner surface 31 and the outer surface 32 are respectively provided with a ring of glue grooves 33, which are used for bonding with the heat sink 1 and the flat glass 41 after filling with liquid silica gel.

[0030] Further, the flat glass 41 is provided with a through hole 5, which is used to release the air between the flat glass 41 and the lens cover 3 when bonding to avoid the influence of trapped air. The diameter is 1 mm.

[0031] Further, the outer surface 32 of the lens cover 3 is provided with several buckle-type connectors 34 on the peripheral edge, and the buckles 341 of the bu...

Embodiment 2

[0034] Please refer to the attached image 3 and attached Figure 4 , an LED lighting module, including a heat sink 1, an LED lamp board 2, a lens cover 3 and a protective glass 4, the lens cover 3 has an inner surface 31 close to the LED lamp board 2 and close to the protective glass 4 The outer surface 32 of the glass 4 .

[0035] Further, the protective glass 4 is a molded curved glass 42, and the molded curved glass 42 has a circle of grooves 421 around its edges.

[0036] Further, the inner surface 31 and the outer surface 32 are respectively provided with no less than a circle of glue grooves 33, which are used for filling liquid silica gel, respectively, with the heat sink 1 and the molded curved glass 42. bonding.

[0037] Further, the molded curved glass 42 is provided with a through hole 5, which is used to release the air between the molded curved glass 42 and the lens cover 3 when they are bonded, so as to avoid the influence of trapped air. 5 has a diameter of...

Embodiment 3

[0042] Please refer to the attached figure 1 and attached Figure 5 , an LED lighting module, including a heat sink 1, an LED lamp board 2, a lens cover 3 and a protective glass 4, the lens cover 3 has an inner surface 31 close to the LED lamp board 2 and close to the protective glass 4 The outer surface 32 of the glass 4 .

[0043] Further, the protective glass 4 is flat glass 41 .

[0044] Further, two circles of gluing grooves 33 are respectively arranged around the inner surface 31 and the outer surface 32 , which are used for bonding with the heat sink 1 and the flat glass 41 after being filled with liquid silica gel.

[0045] Further, the flat glass 41 is provided with a through hole 5, which is used to release the air between the flat glass 41 and the lens cover 3 when bonding to avoid the influence of trapped air. The diameter is 2mm.

[0046] Further, the outer surface 32 of the lens cover 3 is provided with several buckle-type connectors 34 on the peripheral edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com