Friction force test device for reactor control rod driving mechanism

A driving mechanism and test device technology, which is applied in the control of nuclear reactions, reactors, nuclear reactor monitoring, etc., can solve the problems of prone to human error, high physical energy consumption, and slow lifting speed, so as to achieve good reference significance and reduce the exposure dose , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

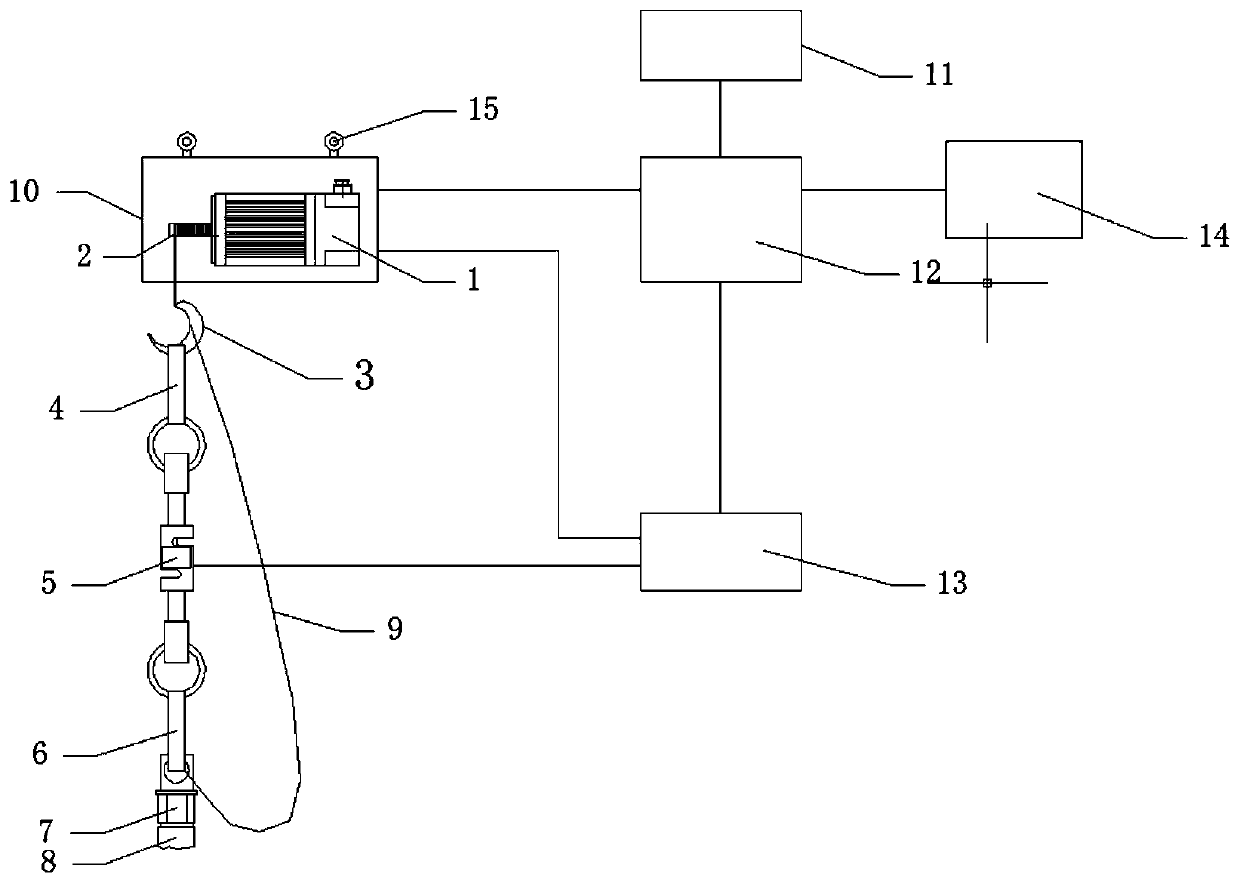

[0024] The friction force test device for the driving mechanism of the reactor control rod provided by the present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0025] Such as figure 1 As shown, the invention provides a reactor control rod driving mechanism friction test device, including: servo motor 1, steel cable 2, hook 3, loop sling, S-type tension sensor 5, driving rod transportation tool 7, driving rod 8. Safety harness 9, driver 10, power supply 11, collector 12, analog signal transmitter 13, industrial computer 14, hanging ear 15, and power cord signal;

[0026] The driver 10 is suspended under the cantilever through the hanging ears 15. The driver 10 is provided with a servo motor 1 inside. The driving end of the servo motor 1 is connected to the hook 3 through a steel cable 2, and the lower end of the hook 3 is suspended with an S-shaped tension through an annular sling-4 Sensor 5, S-type tension sensor 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com