Convenient current terminal replacement system

A current terminal, convenient technology, applied in the direction of circuits, electrical components, coupling devices, etc., can solve the problem that the current terminal is difficult to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

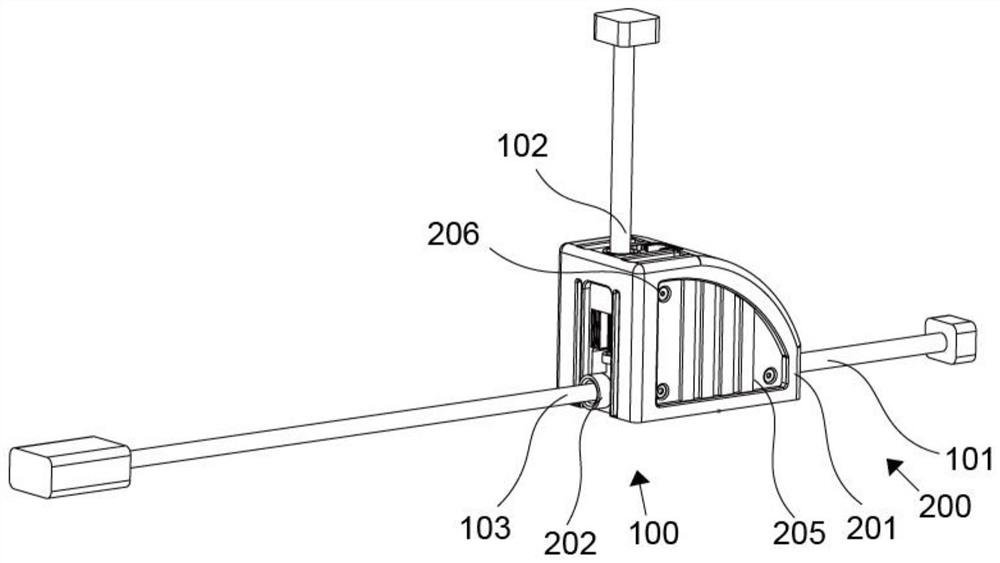

[0027] refer to Figure 1-4 , a convenient current terminal replacement system includes a main body assembly 100, including a main line 101, a backup line 102, and a terminal line 103 connected to the main line 101; The main interface 202 , the active interface 203 cooperating with the main line 101 and the backup line 102 , and the conversion piece 300 arranged in the casing 201 and cooperating with the active interface 203 .

[0028] Specifically, the main body assembly 100 includes a main line 101, a backup line 102, and a terminal line 103 connected to the main line 101; The active interface 203 that cooperates with the line 101 and the standby line 102, and the conversion piece 300 that is arranged in the casing 201 and cooperates with the active interface 203, the conversion piece 300 completes the lossless line switching by making the active interface 203 quickly move to the standby line 102, the main The line 101 and the terminal line 103 are always connected through ...

Embodiment 2

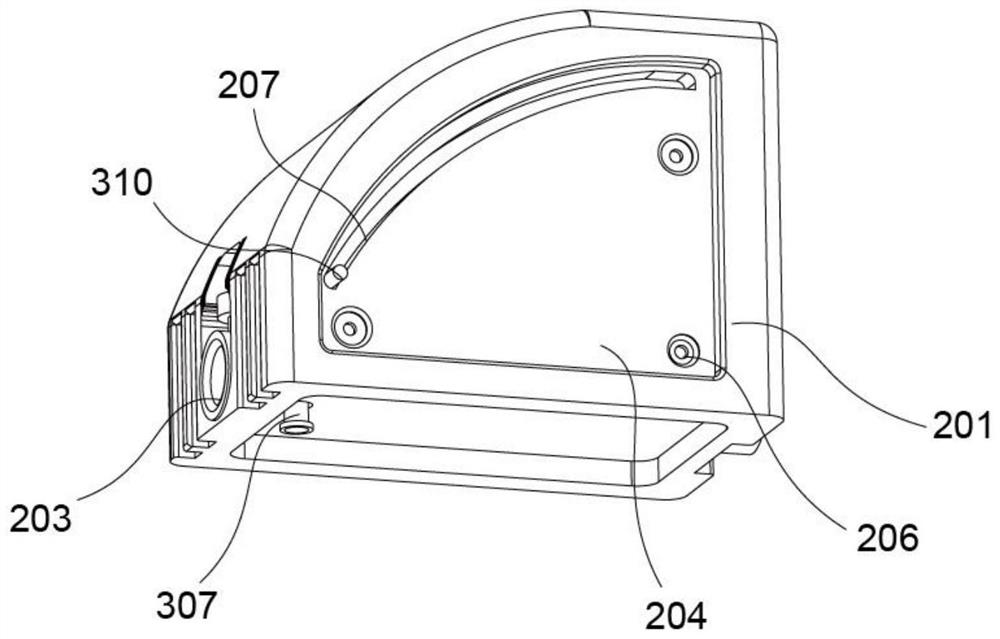

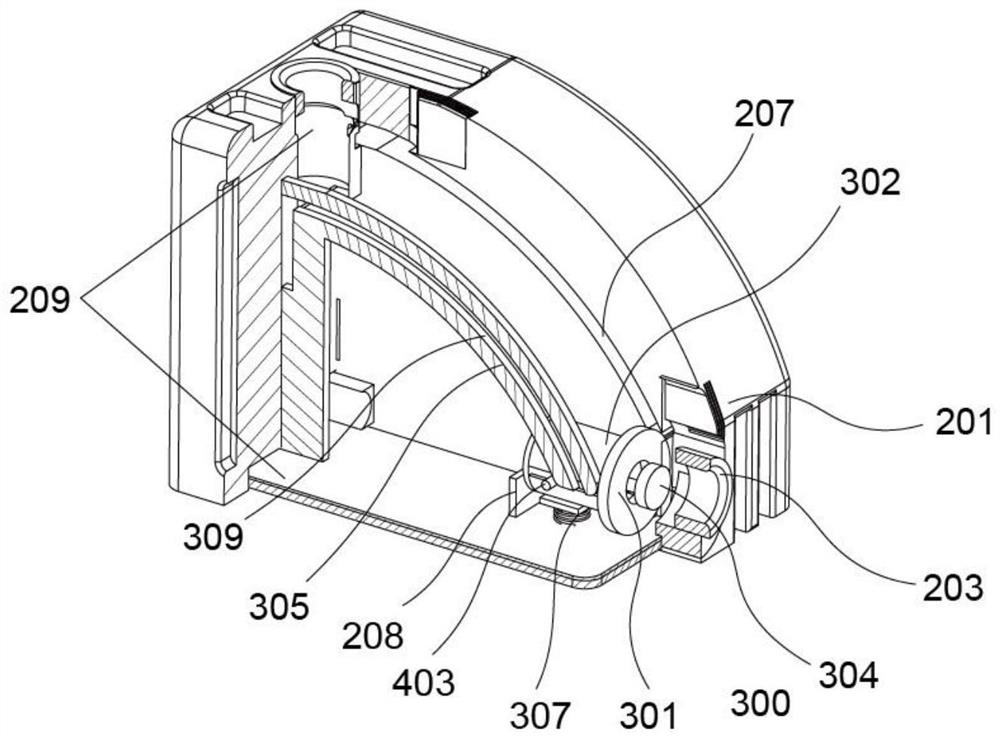

[0031] refer to Figure 1-4 , this embodiment is different from the first embodiment in that: the main interface 202 and the movable interface 203 are respectively arranged at the left and right ends of the casing 201, and the backup line 102 is arranged at the top of the casing 201; A mounting plate 204 and a second mounting plate 205, the first mounting plate 204 and the second mounting plate 205 are provided with more than two mounting holes 206; The movable cavity 302 fixedly connected under the interface plate 301, the bottom of the movable cavity 302 is provided with a first elastic member 303, one end of the first elastic member 303 is fixedly connected with a movable rod 304, and a shelf plate 305 matched with the movable cavity 302, and the interface plate 301 An opening 306 is opened on the top, and the movable rod 304 extends out of the opening 306. The movable rod 304 is provided with a starting member 400; the driving member 307 is arranged below the movable chamb...

Embodiment 3

[0038] refer to Figure 1-4 , This embodiment is different from the above embodiments in that the starting member 400 includes a limit spring 401 arranged on the top side of the movable rod 304, a starting spring 402 arranged on the bottom surface of the moving rod 304, and a starting spring 402 fixedly connected with the starting spring 402. Slider 403, driving rod 307c is arranged on the limit shrapnel 401 below and cooperates with it, is provided with the strip groove 308 that cooperates with starting slider 403 on the movable chamber 302; The limit groove 309 cooperates; the interface plate 301 is provided with a lever 310, the first mounting plate 204 is provided with a movable groove 207 matched with the lever 310, and the lever 310 extends out of the movable groove 207; the bottom of the housing 201 is provided with a support The plate 208 and the supporting plate 208 are located behind the movable chamber 302; a transmission guide 209 is provided between the main inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com