Flavored grease and preparation method thereof

A flavor oil and flavor technology, applied in the field of oil processing, can solve the problems of unstable product quality and difficulty in standardization of fragrant oil products, and achieve the effects of strong overall flavor, stable product quality, and precise and controllable conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention at first provides a kind of preparation method of flavor vegetable oil, and this method comprises the following steps:

[0042] (1) mixing rapeseed and rapeseed oil to obtain a rapeseed / rapeseed oil mixture;

[0043] (2) heat-treating the mixture to obtain a flavored rapeseed / rapeseed oil mixture;

[0044] (3) Separating the flavored rapeseed / rapeseed oil mixture to obtain flavored rapeseed and flavored rapeseed oil.

[0045] In some specific embodiments, a step of pretreating the used rapeseed is also included.

[0046] The pretreatment methods applicable to the present invention include: at least one of cleaning, impurity removal, sieving, soaking, washing, drying (for example, roasting, centrifuging, steaming, drying, etc.); In the method, the means of soaking and / or drying are used for pretreatment.

[0047] In some embodiments, the rapeseed oil suitable for use in the present invention in step (1) includes refined rapeseed oil, quaternary r...

Embodiment 1-3

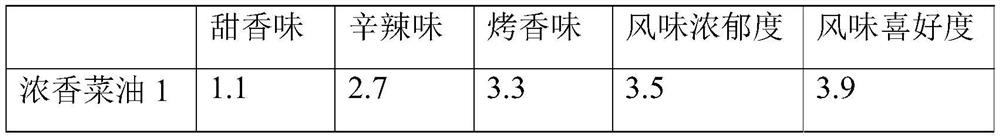

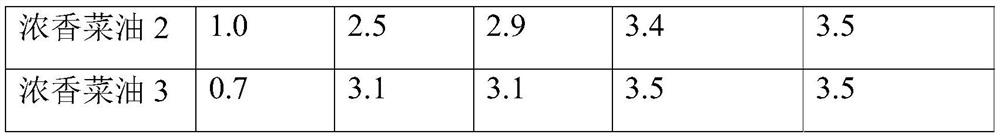

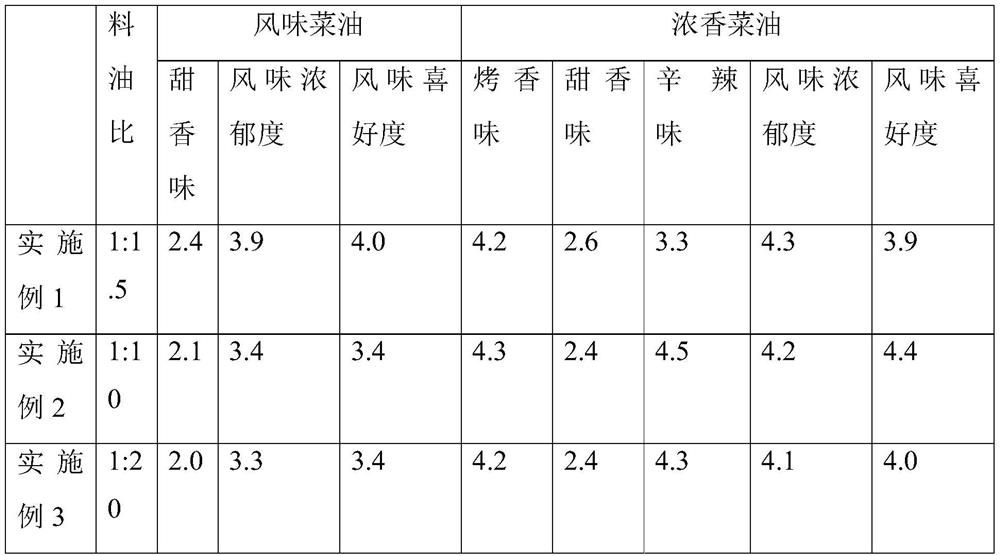

[0099] Commercially available rapeseed and primary rapeseed oil were mixed with different feed-to-oil ratios, and N was introduced into the reactor before heat treatment. 2 Adjust the pressure at 0.5 MPa, heat at 150°C for 30 minutes, and separate the flavored rapeseed and flavored rapeseed oil after the reaction; drain the flavored rapeseed after heating and reaction, and press it into an oil press to obtain crude oil, adding water to the crude oil 1.5%, stirring at 60°C for 0.5h and centrifuging at 8000g to obtain strong coriander oil; see Table 1 for details:

[0100] Table 1

[0101]

[0102] From the above examples, it can be found that, using the method of the present invention, the ratio of material to oil (i.e. the weight ratio of rapeseed to rapeseed oil) is in the range of 1:1.5-1:20, and the resulting flavored vegetable oil is richer in flavor than traditional fragrant vegetable oil. Compared with the traditional strong coriander rapeseed oil, the roasted aroma,...

Embodiment 4-7 and comparative example 1-2

[0104] Mix commercially available rapeseed and fourth-grade rapeseed oil at a feed-to-oil ratio of 1:2, and feed N into the reactor before heat treatment 2 Adjust different pressures, heat at 150°C for 30 minutes, and separate the flavored rapeseed and flavored rapeseed oil after the reaction; drain the heated and reacted flavored rapeseed, then press it into an oil press to obtain crude oil, add water 1.5 %, 8000g centrifugation after stirring at 60°C for 0.5h to obtain fragrant rapeseed oil; see Table 2 for details:

[0105] Table 2

[0106]

[0107] Comparing the above examples and comparative examples, it can be found that the preparation process of the present invention needs to be carried out under airtight conditions with a certain pressure. Under the pressure of 0.05-1MPa, the obtained flavor rapeseed oil is compared with the traditional fragrant rapeseed oil in terms of flavor richness and local flavor. The degree of preference is equal, and the sweet flavor is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com