Composition control device, method and high-throughput preparation system for metal materials

A technology of regulating devices and metal flakes, applied in the direction of mixing methods, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of high strength, high melting point of metal materials, harsh preparation conditions, etc., to improve accuracy , the effect of mixing powder evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

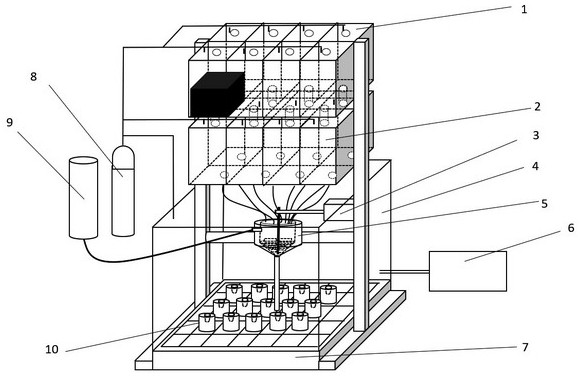

[0031] Specifically, the present invention mainly relates to composition control devices in high-throughput preparation systems for metal materials, such as figure 1 As shown, the component control device of the preparation system includes a powder loading part 1, a powder mixing part 2 and a powder mixing part 5 arranged in sequence from top to bottom.

[0032] The powder loading part 1 has a plurality of mutually independent powder loading bins, and the lower part of each powder loading bin is provided with a screen (indicated by the black area in the figure).

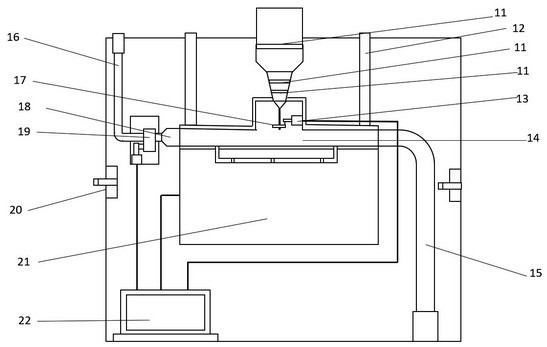

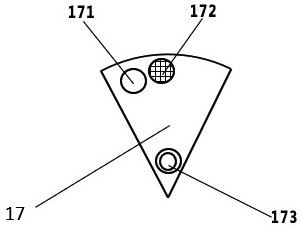

[0033] The powder dispensing section 2 has a plurality of powder dispensing bins, weighing bins and weighing platforms that are independent of each other and correspond to the powder loading bins one by one; specifically, as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com