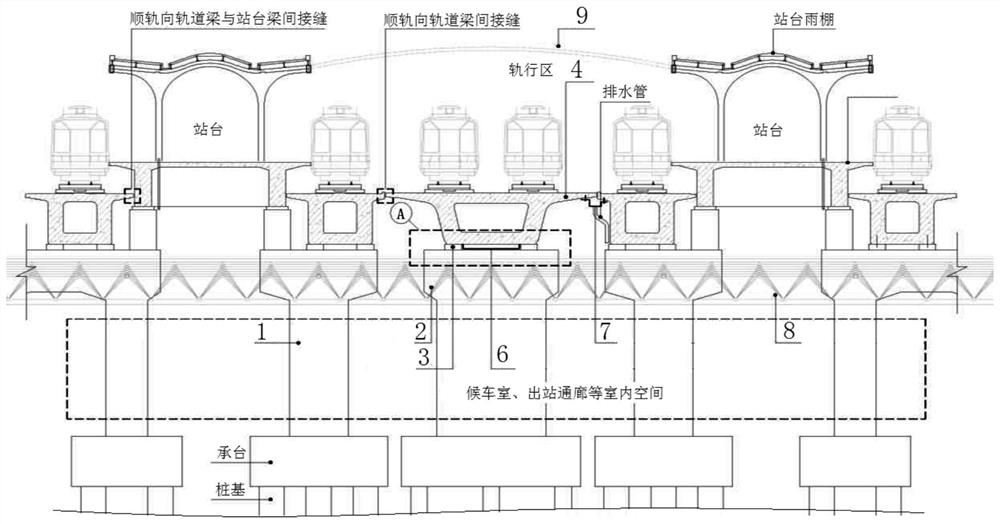

Waterproof and drainage structure at elevated railway bridge column cap

A technology for waterproofing and drainage and railway bridges, which is applied to drainage structures, bridges, waterway systems, etc., and can solve problems such as column cap leakage, failure to ensure seamless lapping of bridge piers, etc., and achieve the effect of not increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

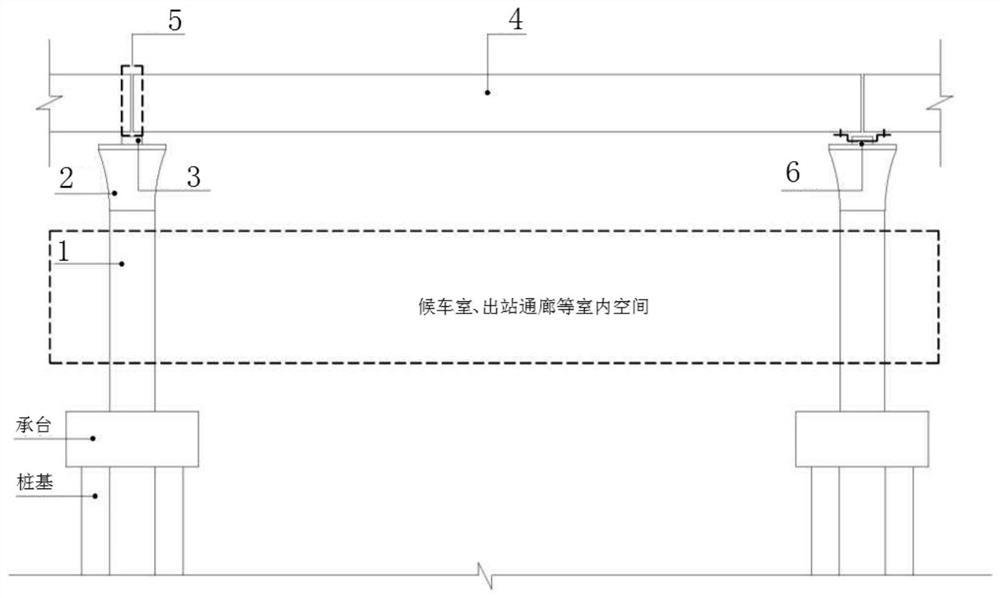

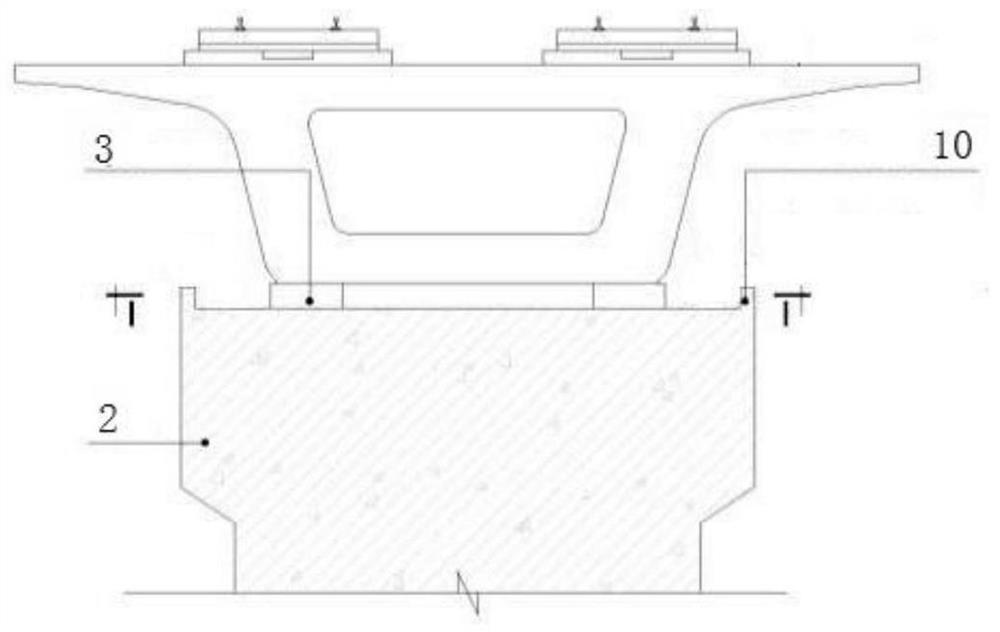

[0043] A kind of waterproof and drainage structure at the post cap of elevated railway bridge in this embodiment, such as Figure 3-5 As shown, it includes a water retaining sill 10 and a drainage assembly. The water retaining sill 10 is arranged on the top of the column cap 2 and is circumferentially closed. The horizontal projection of the water retaining sill 10 surrounds the horizontal projection of the vertical rail on the top of the column cap to the seam 5 , so that the seepage water completely falls into the area surrounded by the water retaining sill 10 , the drainage assembly includes a drain 11 for draining water in the area surrounded by the water retaining sill 10 and a drain pipe 12 connected to the drain 11 .

[0044] More specifically, in this example:

[0045] The water retaining sill 10 is arranged around the top edge of the column cap 2, and is used to collect water leaking from the vertical rail at the top of the column cap to the seam 5. Further preferabl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap