Method for maintaining inspection well without cutting off water

A technology of inspection wells and inspection boxes, which is applied in waterway systems, water conservancy projects, water supply devices, etc., can solve the problems that inspection wells and pipelines cannot realize non-stop construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

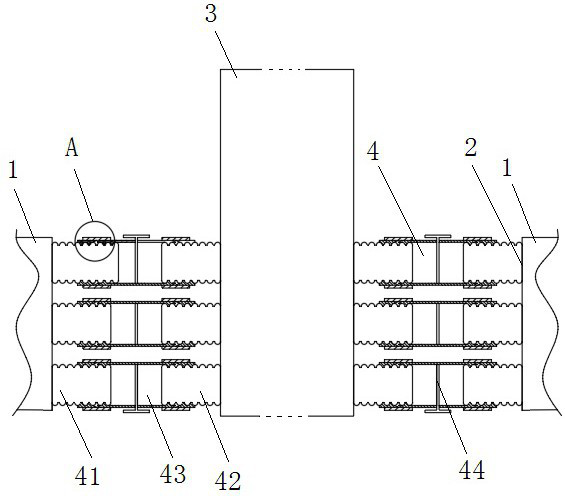

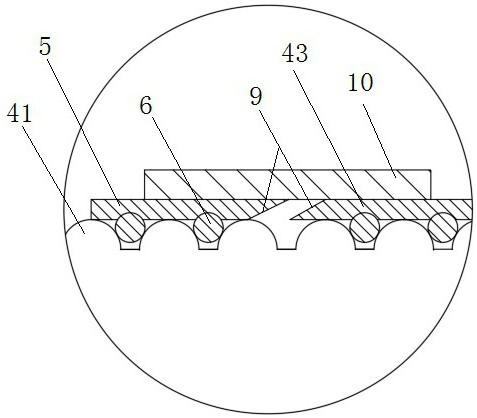

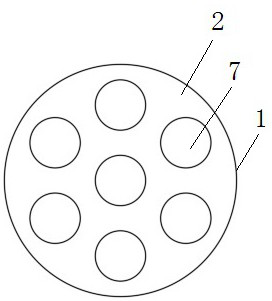

[0034] Embodiment 2, a maintenance method for inspection wells without stopping water, the transfer pipeline includes two sections of flexible pipes and two sections of hard pipes, the two sections of hard pipes are provided with valves for controlling on-off, when replacing the sealed box, First close all the valves in the two transfer pipes connected to the upstream and downstream main pipes 1 respectively, and then remove part of the pipes between the closed valves from the sealed box, and connect the removed pipes to each other. Finally, open the valve so that the upstream and downstream main pipelines 1 are connected through the sealed box and the newly connected pipeline at the same time. Remove it from the inspection well, hoist the new sealed box to the inspection well, and connect the transfer pipes to the new sealed box one by one, and open the corresponding valves after all the transfer ports on the new sealed box are connected to the transfer pipes .

[0035] Othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com