Alloy furnace steel remaining amount on-line monitoring system

A monitoring system and alloy furnace technology, applied in the directions of measuring devices, surveying and navigation, measuring inclination, etc., can solve problems affecting the overall output of alloy furnaces, large differences in employee operations, difficult to trace and count, etc., to achieve convenient assessment and traceability, It is convenient to inquire about services and improve the effect of overall output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

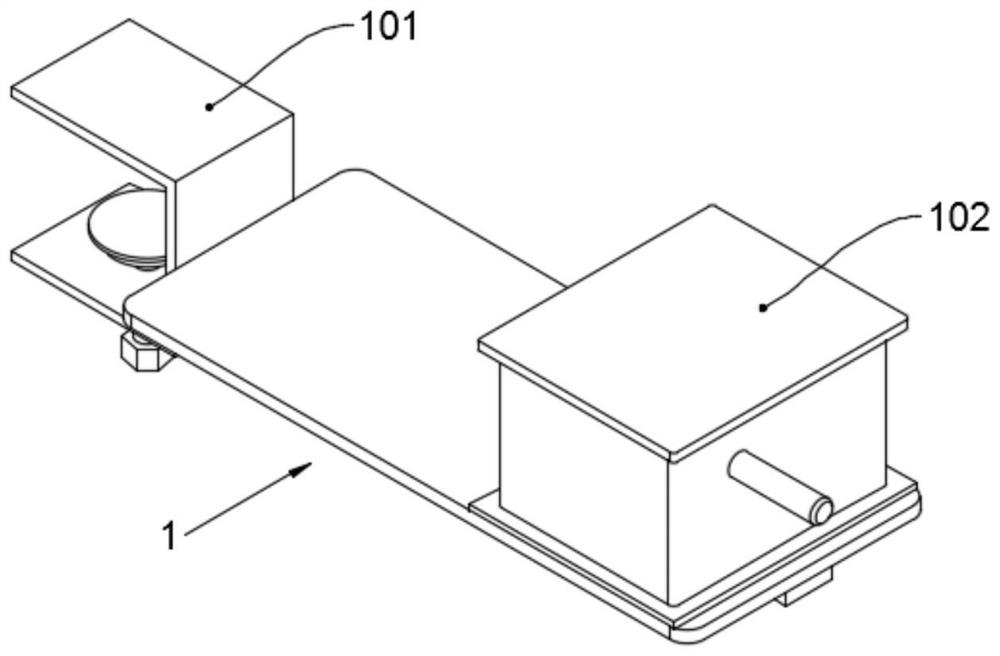

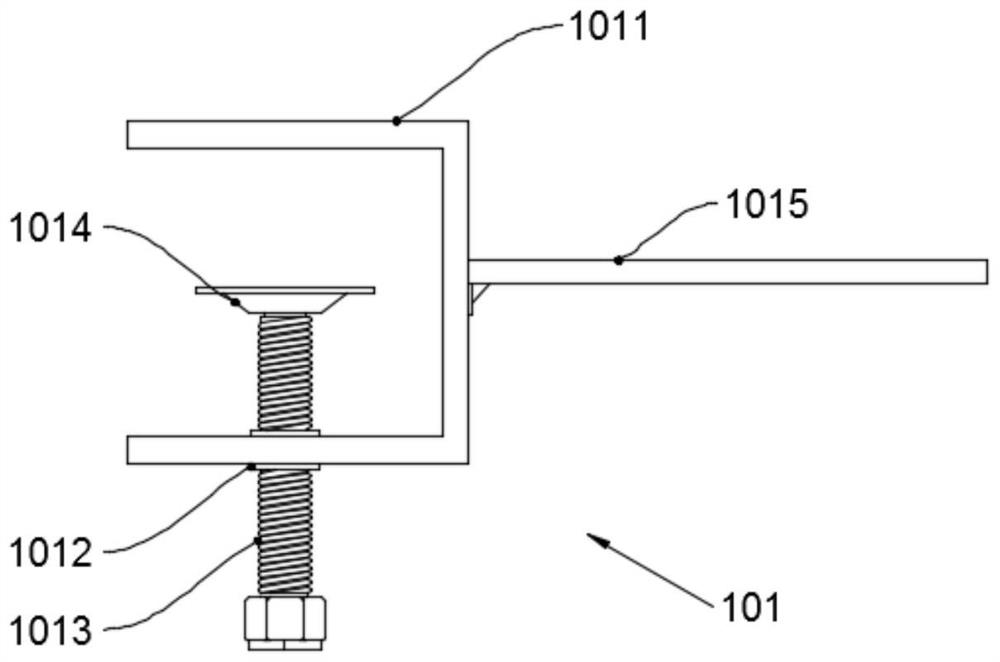

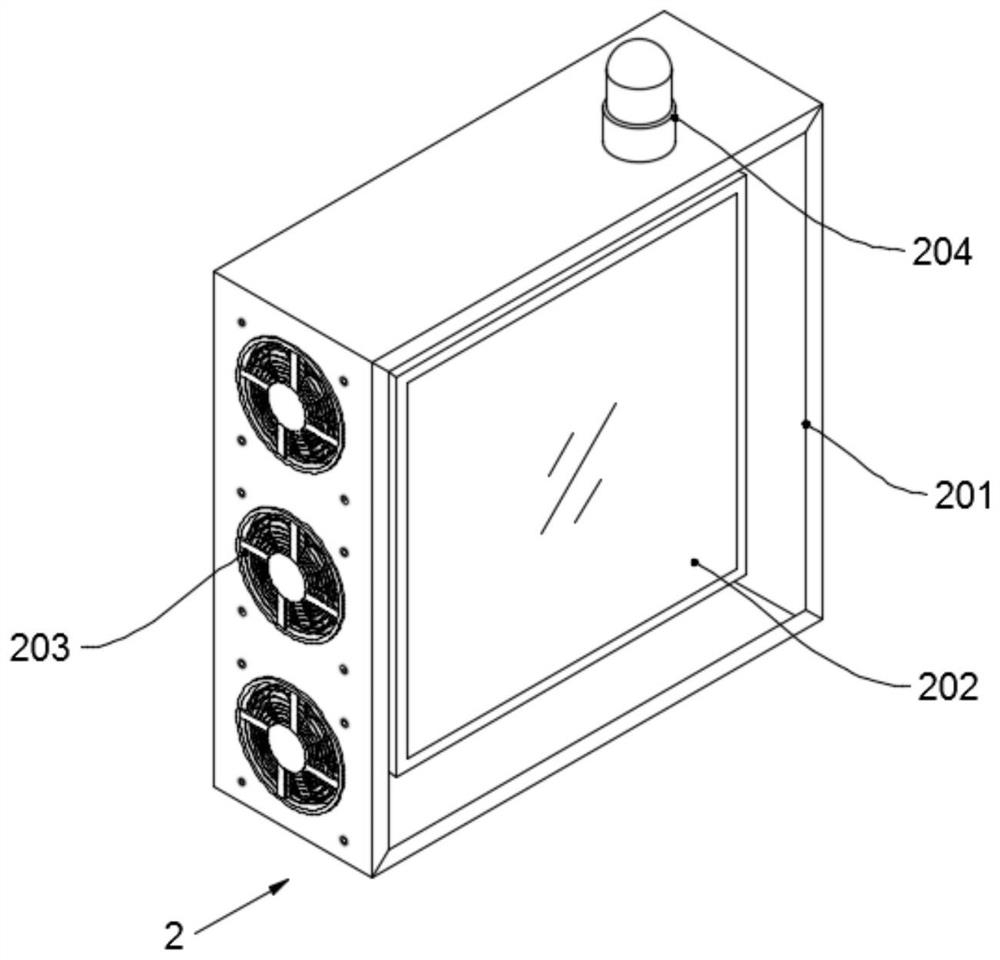

[0024] Example: such as Figure 1-4 As shown, an on-line monitoring system for steel remaining in an alloy furnace in the present invention includes a monitoring module 1 and a display module 2. The monitoring module 1 includes an installation fixture 101 and an inclination sensor 102. The installation fixture 101 includes a fixing frame 1011, and the fixing One side of the frame 1011 is horizontally connected with a fixed plate 1015, and the inclination sensor 102 is fixedly installed on the top side of the fixed 1015; the display module 2 includes a heat insulation box 201 and a display integrated machine 202, and the displayed integrated machine 202 is fixedly installed Inside the heat insulation box 201, the display all-in-one machine 202 is composed of a data access module, a data processing module, a data display module, a display, a data storage module, a data early warning module, an alarm module and a data sending module. The access module, the data display module, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com