Method and system for monitoring grouting process on site

A process monitoring and on-site monitoring technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of large distribution range of recorders, limited supervision personnel, and difficulty in supervision, so as to ensure the quality of grouting projects and prevent The effect of grouting works out of control and ensuring reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The grouting field process monitoring method of this embodiment comprises the following steps:

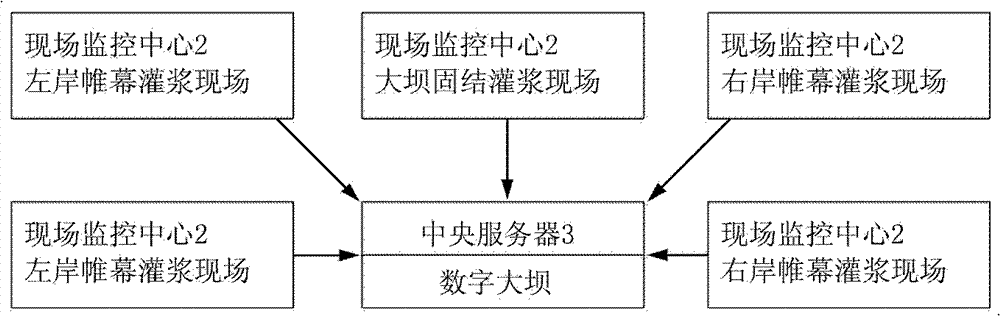

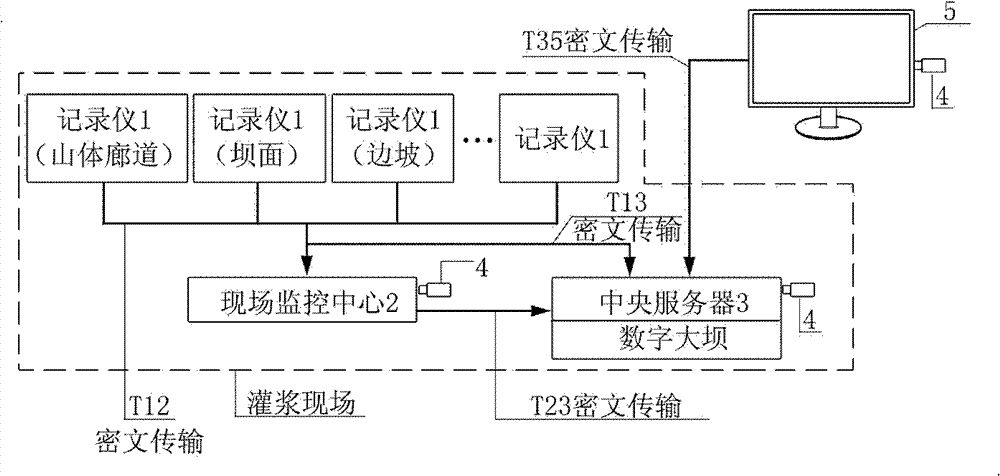

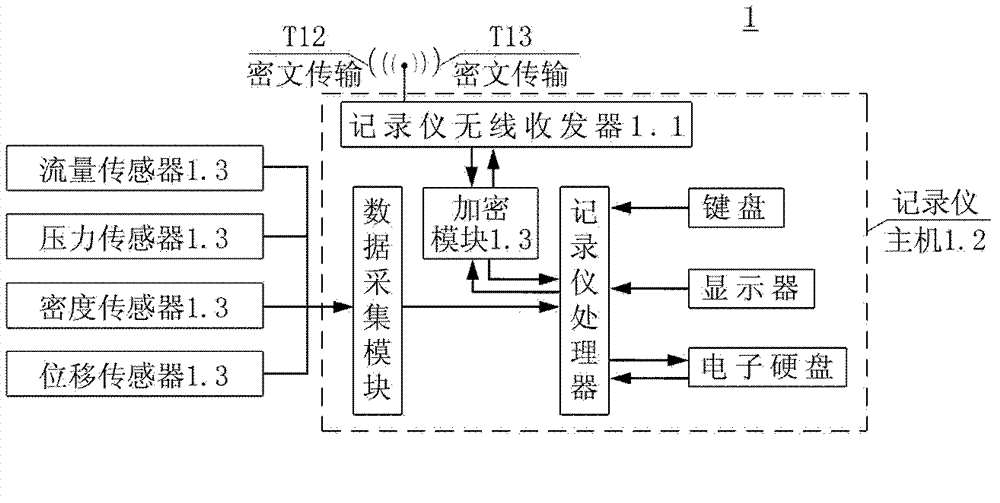

[0021] 1) The monitoring system with the following characteristics is set: in this embodiment, the transmission network T between the recorder 1 and the on-site monitoring center 2 12 and transmission between recorder 1 and central server 3 13 All are wireless. ① see figure 1 , in a grouting project, there are multiple grouting sites distributed according to the construction surface: left bank curtain grouting site, right bank curtain grouting site, dam consolidation grouting site...etc. An on-site monitoring center 2 is added to each grouting site, that is, the left bank curtain grouting on-site monitoring center, the right bank curtain grouting on-site monitoring center, the dam consolidation grouting on-site monitoring center... See figure 2 , each grouting site has a plurality of grouting recorders 1 distributed in mountain corridors, dam surfaces, side slopes, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com