A midpoint clamp circuit, control device and control method

A clamping circuit and control equipment technology, which is applied to electrical components, output power conversion devices, and AC power input into DC power output, etc. Achieve the effect of improving the reliability of the circuit, improving the service life, and avoiding overvoltage damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

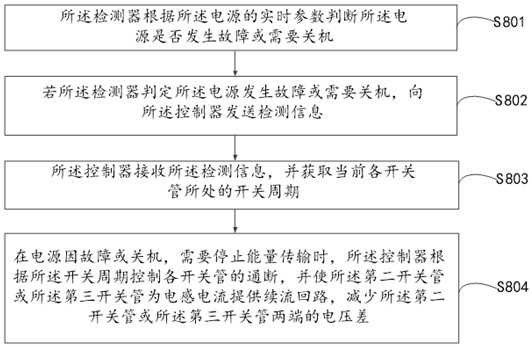

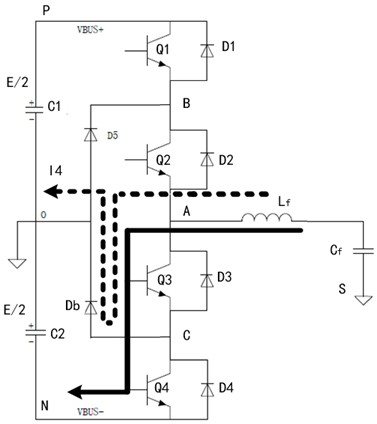

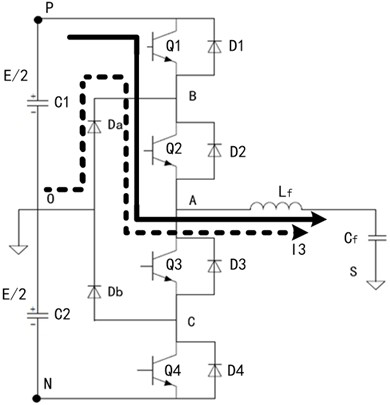

[0057] In the first embodiment, corresponding to the above image 3 For the problems involved in the midpoint clamping circuit shown, if the controller 502 acquires that the current switching cycle is a positive half cycle, control the first switching tube Q1, the third switching tube Q3 and the fourth switching tube Q4 to be disconnected, and control The second switch tube Q2 is turned on. Further, on the premise of controlling the first switching tube Q1, the third switching tube Q3 and the fourth switching tube Q4 to be turned off, the second switching tube Q2 can be controlled to maintain a conduction state within a preset period of time, after the preset period of time , switch the second switching tube Q2 from the on state to the off state. Wherein, the specific value of the preset time period can be customized by the user according to historical experience or actual needs.

[0058] see Figure 6 , Figure 6 It is one of the schematic diagrams of the current directio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap