A control method and control system for tool change in a robot tool magazine

A control method and robot technology, applied in manufacturing tools, metal processing machinery parts, positioning devices, etc., can solve problems such as the operator's inability to change the robot tool change program, the uneven operation ability of the operator, and the heavy workload, etc. The effect of reducing programming difficulty, reducing programming workload, and ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

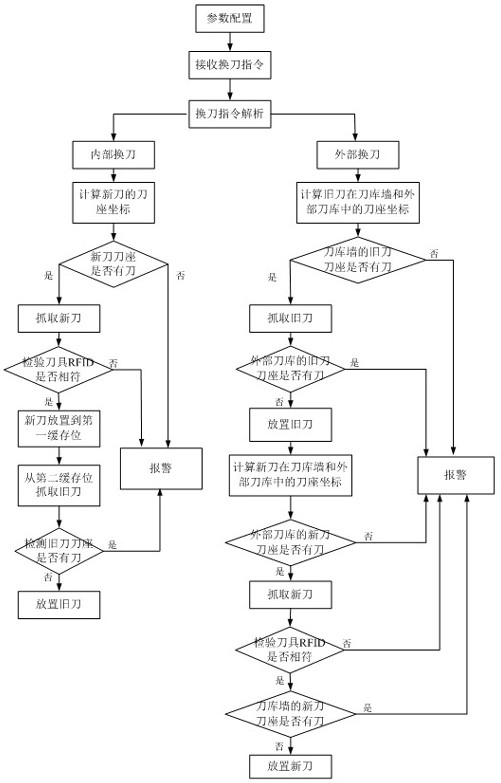

[0060] like figure 1 As shown, a method for controlling tool change in a robot tool magazine of the present invention comprises the following steps:

[0061] Step 1: According to the structure of the tool magazine wall and the external tool magazine, configure the parameters of the tool magazine wall and the external tool magazine. The parameters include the number of tool holders, the number of tool holders, the theoretical offset and the actual offset of each tool holder ;

[0062] During specific implementation, configuring the number of tool holders is specifically: configuring the number of tool holders installed in each row of the matrix tool magazine wall and the external tool magazine and the number of rows of the matrix tool magazine wall.

[0063] During the specific implementation, the configuration of the theoretical offset of the tool seat in the tool magazine wall is as follows: in the coordinate system of the tool magazine wall, configure the X-direction offset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com