Stamping die for plastic plate of environment-friendly science and technology equipment and using method of stamping die

A technology for stamping dies and plastic plates, applied in the field of stamping dies, can solve the problems of being easily embedded in the die, unable to separate the plastic plates, and unable to be easily taken out, etc., and achieves the effect of avoiding damage, good stamping effect and improving stamping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

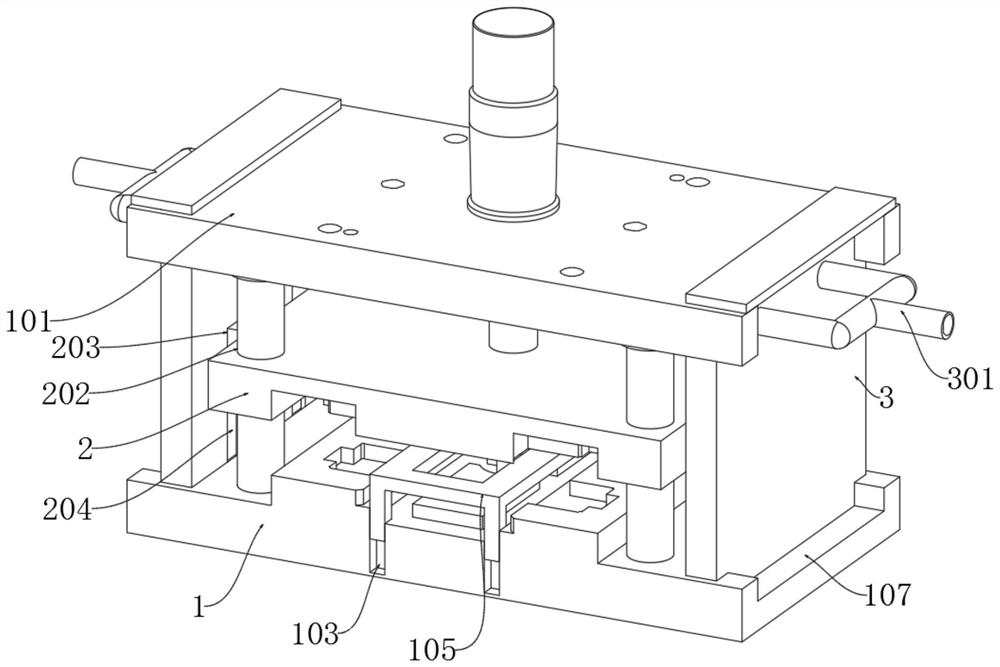

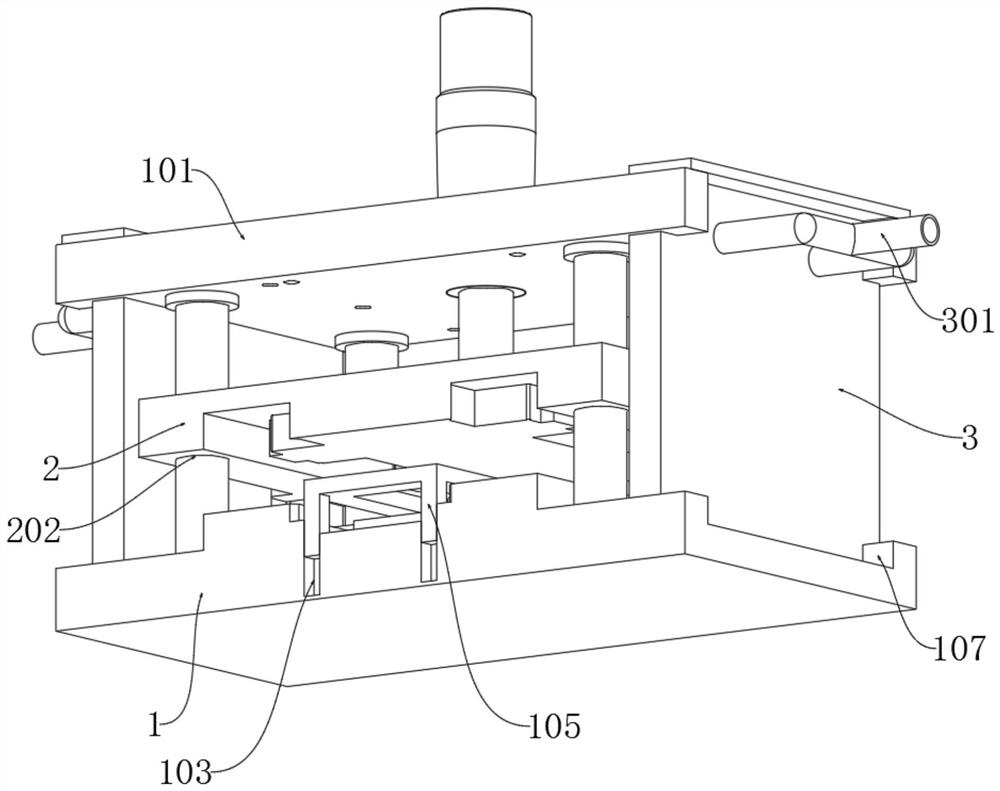

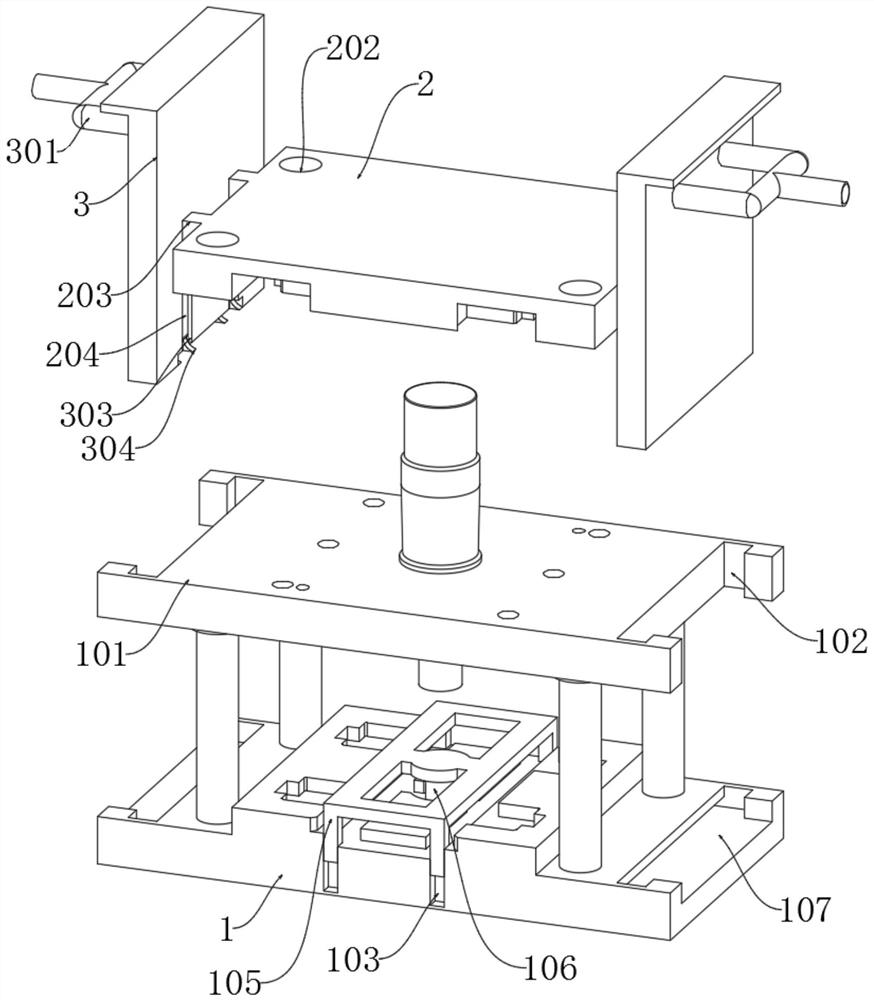

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The invention provides a stamping die for plastic plates of environmental protection technology equipment and its use method, including a main body 1; There is a moving part 2, and the outer end of the moving part 2 is equipped with a moving sealing mechanism. The moving sealing mechanism can move up and down following the moving part 2, so that water can always enter the inside of the circulation tank 201, so that the water will not leak. The moving part 2 is The top mold body, the moving part 2 is a rectangular structure, and a side part 3 is respectively installed on both sides of the main body 1 and the moving part 2. The side part 3 is an L-shaped structure, and the side part 3 is inserted into the limit groove 102 and the outer groove 107. Inside, the side pieces 3 are installed on both sides of the main body 1, so that hot water can circulate inside the circulation tank 201, and then the plastic plate can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com