Film covering equipment for combination plate production

A technology for bonding boards and equipment, which is applied in the field of cover film equipment for bonding board production. It can solve problems such as quality deviation, unsatisfactory product quality, and inability to fix the bonding boards. It achieves continuous pressing, ensures the pressing effect, and facilitates automatic The effect of leaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

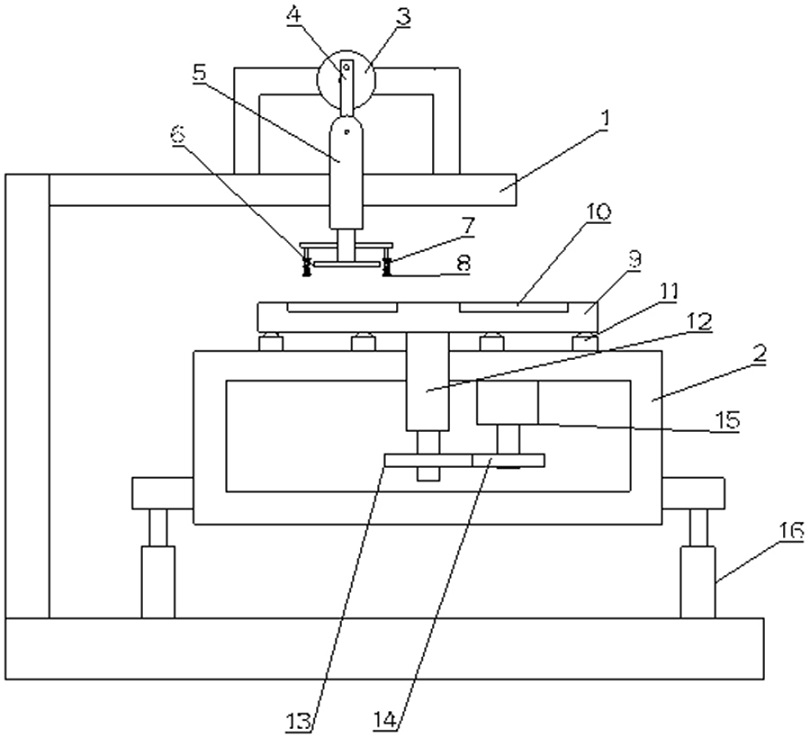

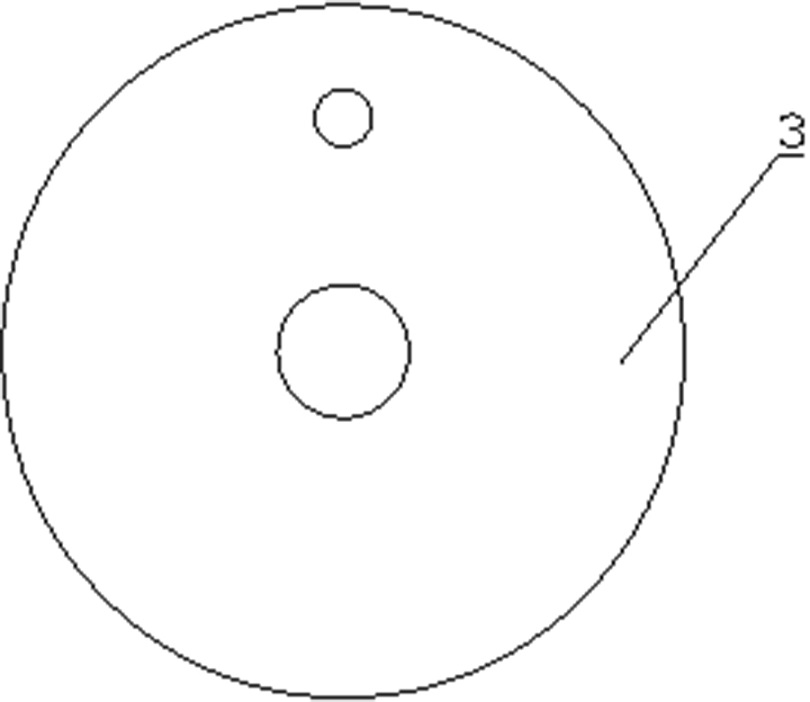

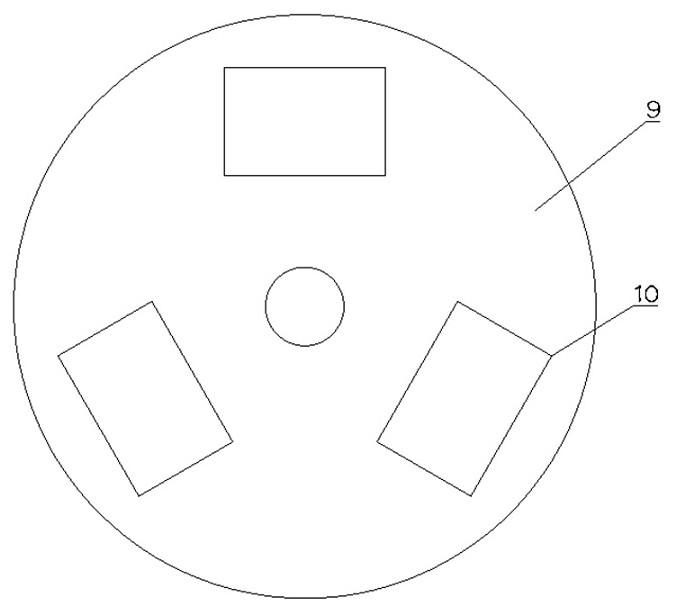

[0027] see figure 1 , in Embodiment 1 of the present invention, a structural diagram of a covering film equipment for bonded board production provided in the embodiment of the present invention, including: equipment main body 1, feeding mechanism and pressing mechanism; equipment main body 1, used for supporting; The feeding mechanism is arranged on the main body 1 of the equipment, and is used to store the bonding plates for covering the film. The feeding mechanism includes a turntable 9 that rotates intermittently. Groove 10, so as to realize the continuous addition of bonding plates to the turntable 9; the press-fit mechanism includes a slide bar 5 that is reciprocally slid up and down on the device main body 1, and the middle position of the bottom of the slide bar 5 is provided with a pressing plate 6 , fixing components are arranged on both sides of the extruding plate 6 , and the fixing components include a plurality of collision balls 8 elastically arranged on the slid...

Embodiment 2

[0030] see Figure 1~4 The main difference between this embodiment 2 and embodiment 1 is that in order to drive the turntable 9 to rotate intermittently, the bottom of the turntable 9 is fixedly equipped with a support shaft 12, and the support shaft 12 is rotatably arranged on the support base 2, and the support base 2 is arranged on the main body 1 of the device, and an intermittent mechanism for driving the supporting rotating shaft 12 to rotate intermittently is arranged inside the support base 2 .

[0031] As a preferred embodiment of the present invention, the intermittent mechanism may be an incomplete gear structure or a ratchet mechanism. The frequency of the intermittent movement of the intermittent mechanism is consistent with the frequency of the vertical reciprocating movement of the slide bar 5 .

[0032] As a preferred embodiment of the present invention, the intermittent mechanism includes a first gear 13 fixedly sleeved on the supporting shaft 12, the first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com