Synchronous folding type dust cover

A dust cover and foldable technology, which is applied in the fields of pollution prevention methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to guide the dustproof effect, poor elasticity and synchronization of the dust cover, etc. Solve the effect of large occupied space, improved reliability and expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

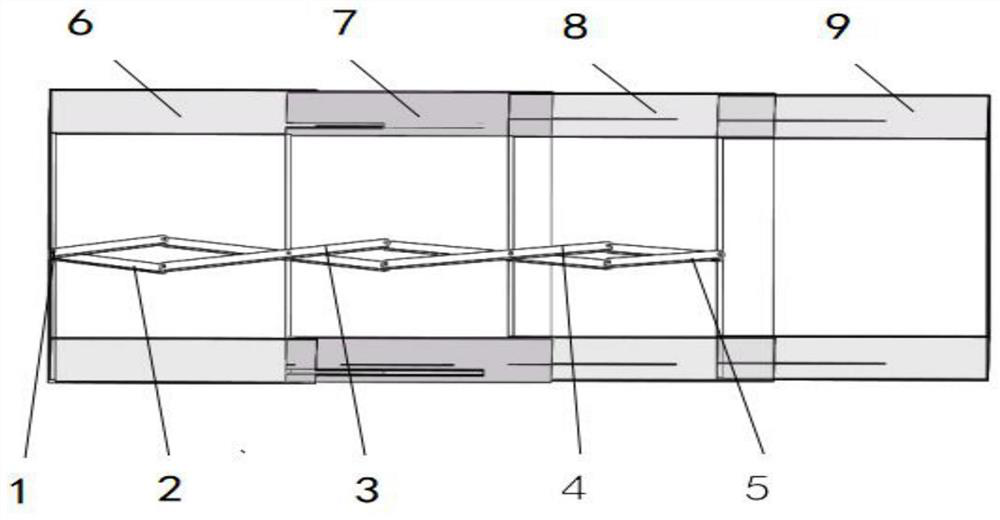

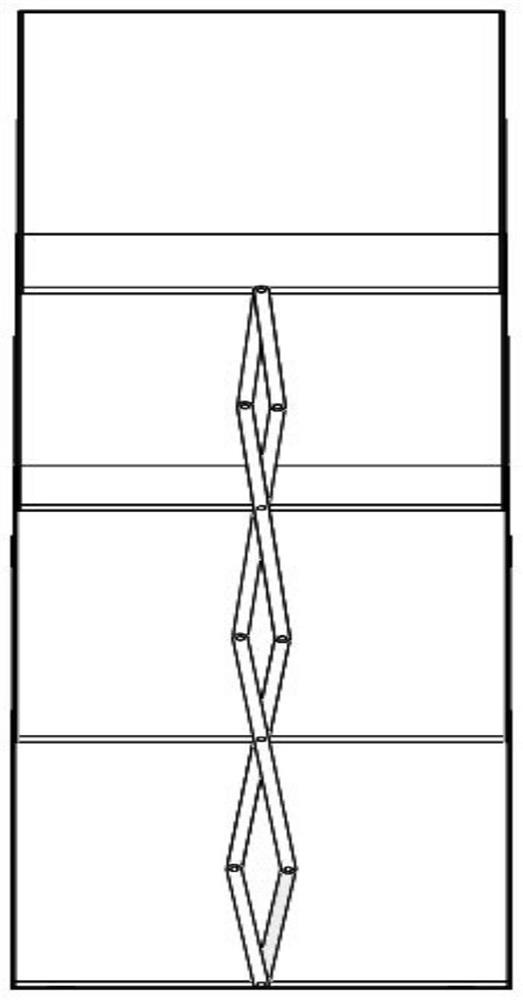

[0012] Such as figure 1 , the multi-stage synchronous folding dust cover provided by the present invention includes a first-stage base body 6, the first-stage base body 6 is connected to the slider 1 at the first (end) end of the guide rail by bolts, and the fourth-stage base body 9 is installed by bolts at the other end of the rail. When the slider of the guide rail moves, the two rods 2 placed in the first-level matrix 6 are interlaced with the rods 3 to cause the telescopic movement of the second-level base 7. At the same time, the rods 4 and 5 realize The same staggered movement causes the telescopic movement of the third-stage base body 8 and the fourth-stage base body 9 , thereby realizing multi-stage synchronous transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com