Seam allowance structure, tire and attaching method

A technology of nipple and tire, which is applied in the field of tire manufacturing, can solve the problem of easy warping of the edge of the nipple, and achieve the effect of solving the problem of easy warping and avoiding warping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

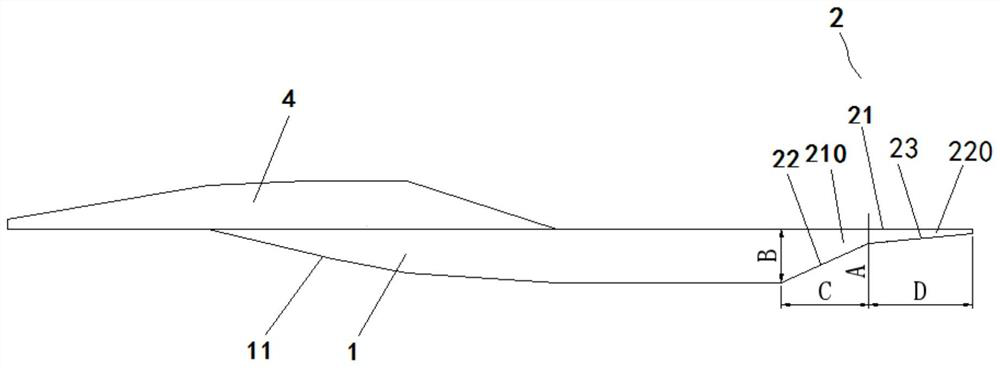

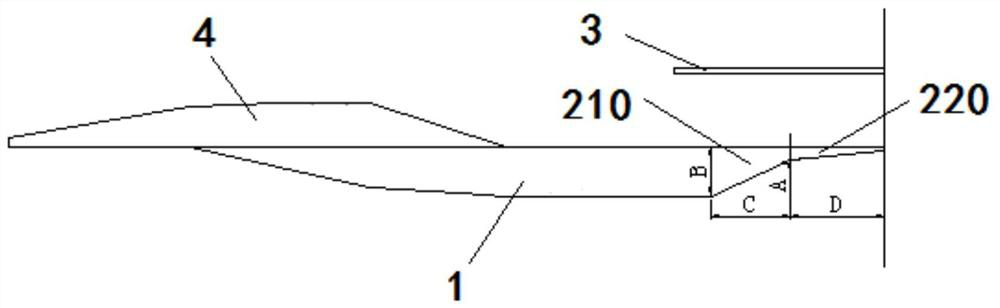

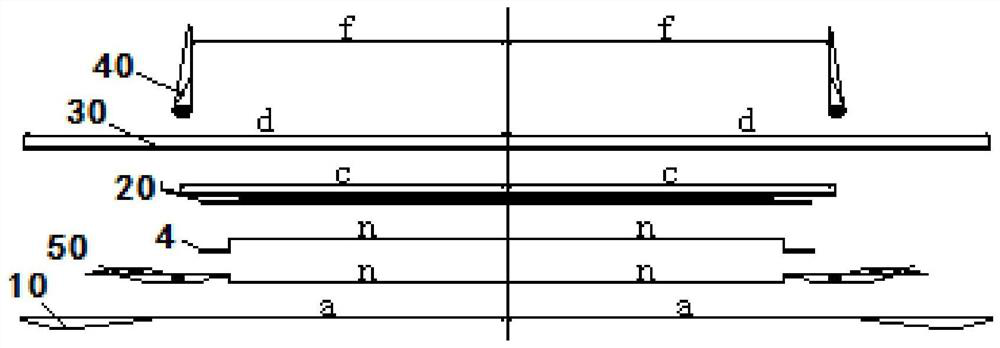

[0040] For the subport structure of this embodiment, see Figure 1 to Figure 4 , used to be arranged between the sidewall 10 and the inner liner 20 of the tire, the slit structure includes: the first bonding part 1, the first bonding part 1 is bonded to the sidewall 10; the second bonding part 2, The second bonding part 2 is connected with the first bonding part 1; the second bonding part 2 includes a second bonding surface 21 for bonding with the inner lining layer 20, and the second bonding part 2 has a The bonding surface 21 is opposite to a first bonding surface 22 and a second bonding surface 23 , and the second bonding surface 23 is disposed at an end of the first bonding surface 22 away...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap