Ceramic sheet clamping system

A ceramic thin plate and hand-clamping technology, applied in ceramic molding machines, conveyor objects, unloading devices, etc., can solve problems such as damage, high handling costs, and low handling efficiency, and achieve the effect of ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

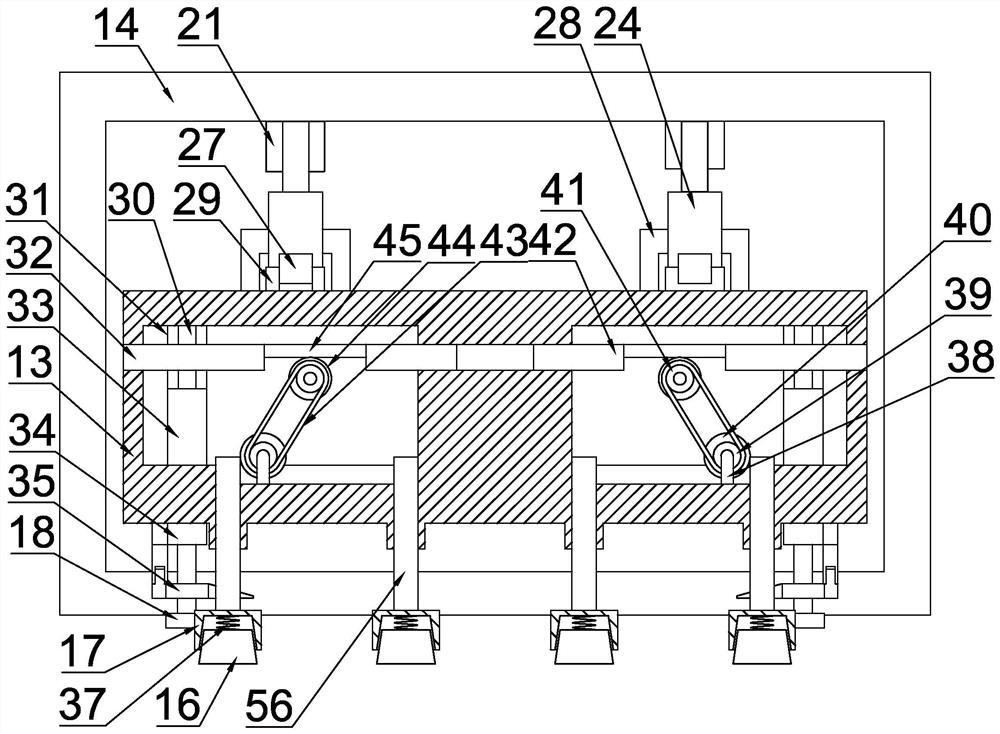

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

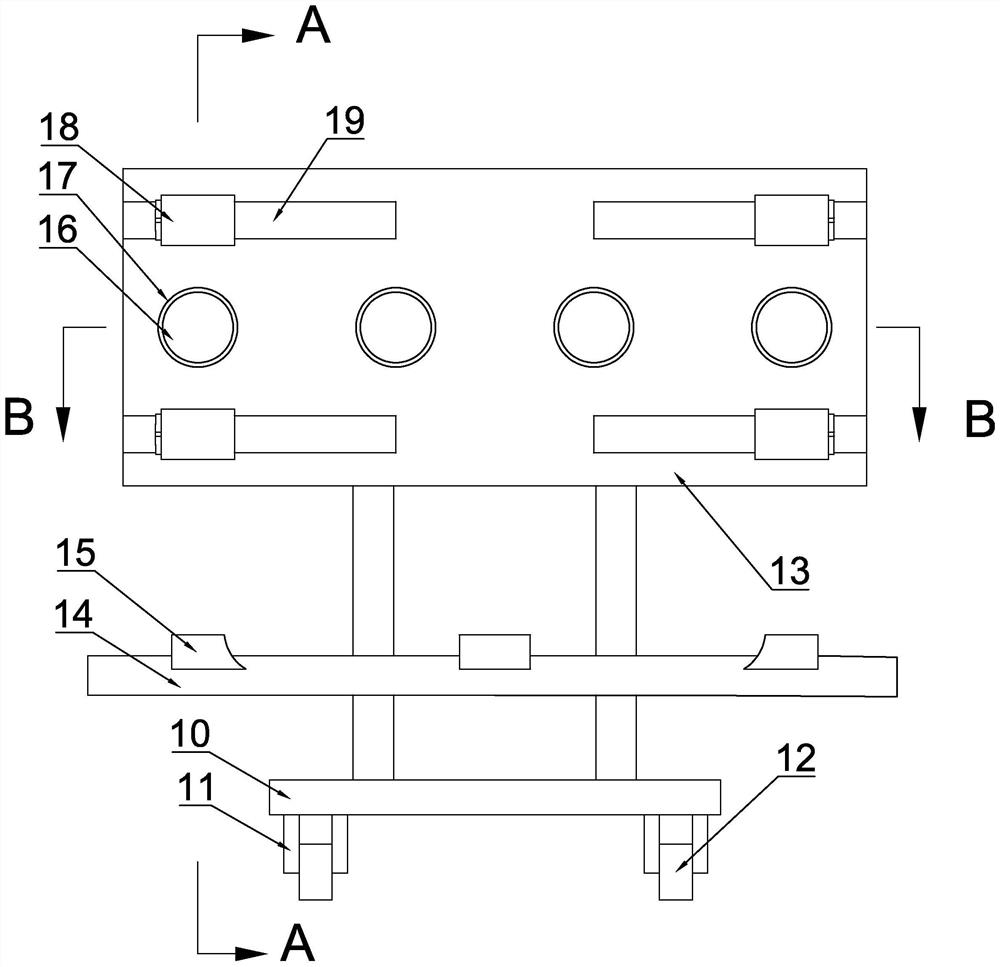

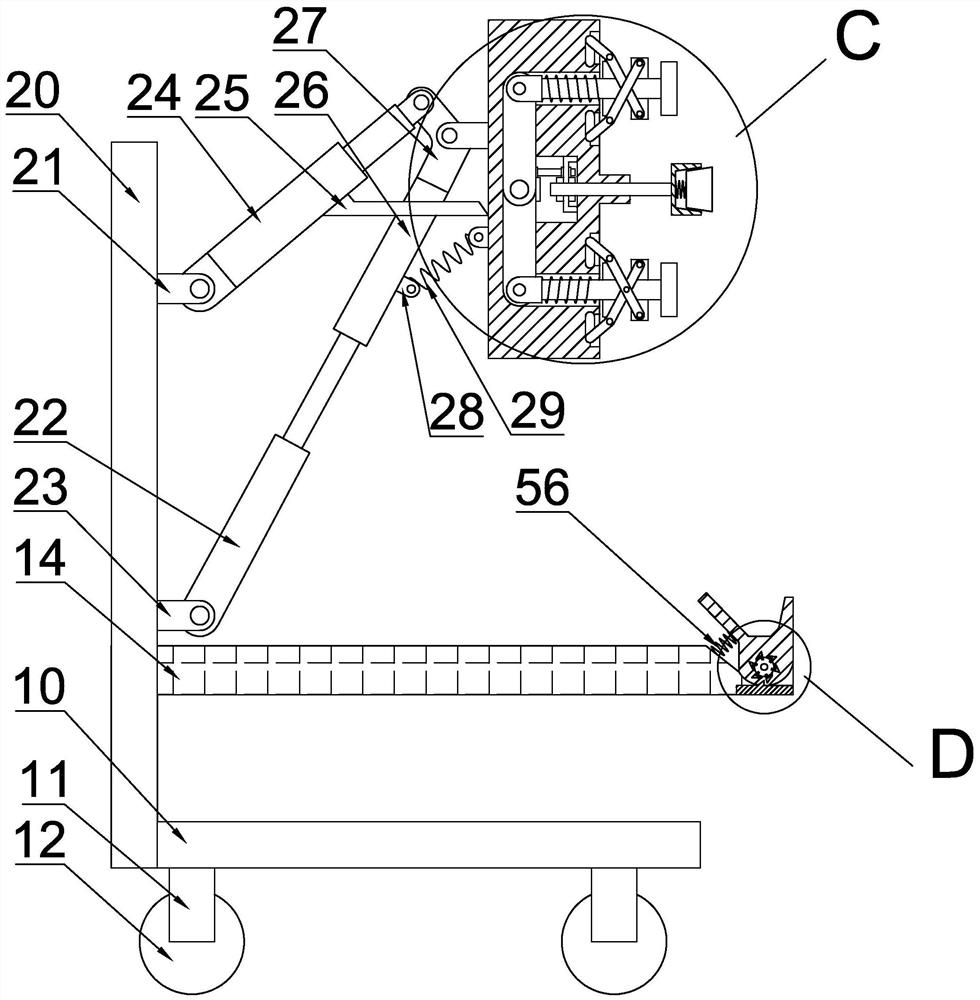

[0025] Such as figure 1 As shown, a ceramic thin plate clamping system includes a housing 10, the lower end of the housing 10 is fixed with a wheel device, the rear side of the housing 10 is fixed with a support rod 20, and the support rod 20 is fixed with a docking support plate 14, A ceramic thin plate docking device is established on the docking support plate 14, and the ceramic thin plate docking device is used to place the ceramic thin plate.

[0026] Such as figure 1 and figure 2 As shown, the wheel device includes four groups of wheel fixing frames 11 symmetrically and fixedly arranged at the lower end of the casing 10 , and wheels 12 are rotatably arranged on each group of wheel fixing frames 11 .

[0027] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com