Construction method for penetrating large-pipe-diameter jacking pipe through sea wall

A construction method and large-diameter technology, which can be used in dikes, artificial islands, water conservancy projects, etc., and can solve problems such as bank collapse, settlement, disturbance, and internal holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

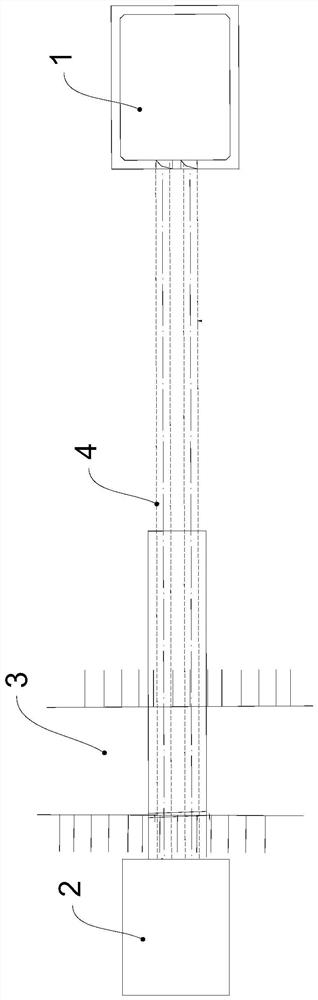

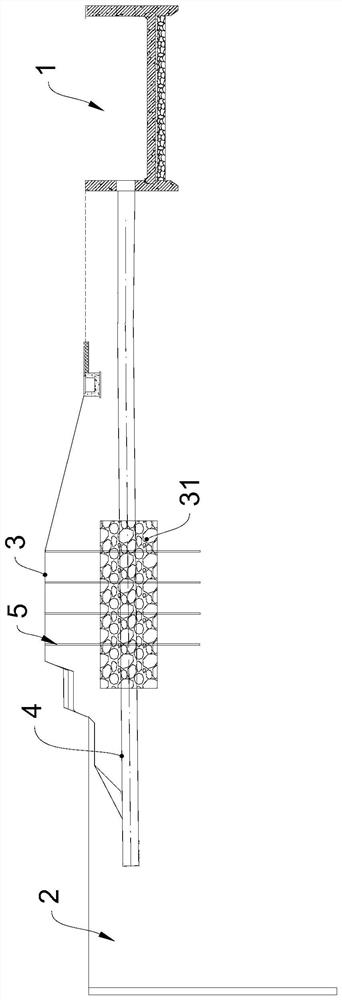

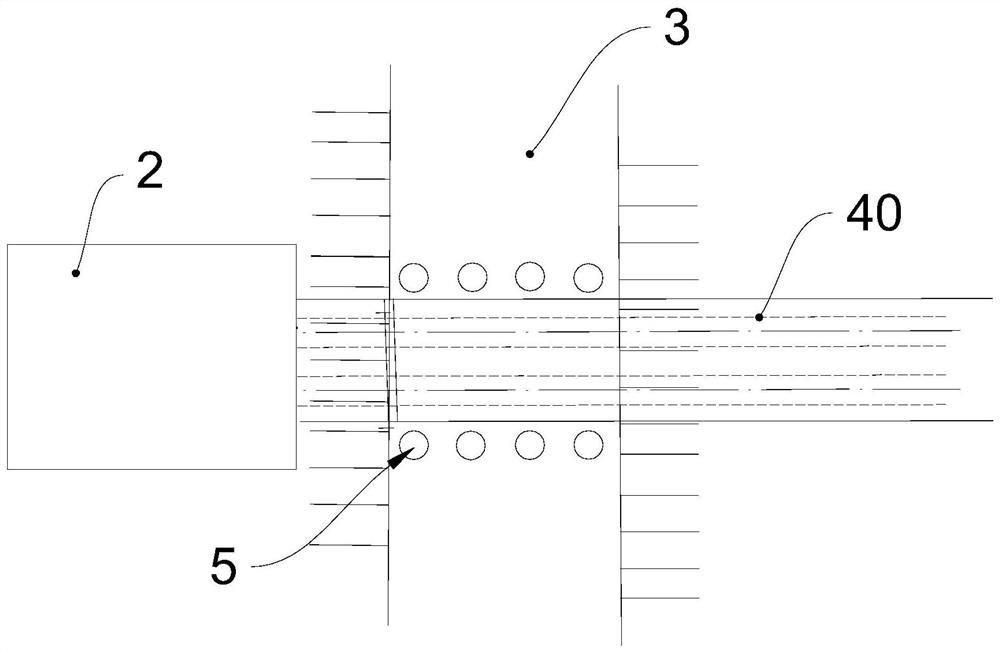

[0026] see Figures 1 to 6 , a kind of large-diameter pipe jacking construction method that the present embodiment provides to pass through the seawall, the seawall 3 is provided with a riprap area 31, comprising the following steps:

[0027] Step 1, measure and stake out, mark the direction of two pipelines 40 on the seawall 3, the two pipelines 40 are arranged longitudinally, the pipeline direction 40 includes the position of the pipeline 4 and its extension direction, and then on both sides of the pipeline direction 40 A plurality of first grouting hole positions are marked, and the plurality of first grouting hole positions are arranged and extended along the extension direction of the pipeline trend 40 .

[0028] Step 2: Construct the working well 1. On the inner side of the seawall 3, 350m away from the seawall, use the caisson method to construct the working well 1. The working well 1 is located at the first end of the pipeline direction 40. The working well 1 has a squ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap