Solid rocket cold separation device and using method thereof

A solid rocket, cold separation technology, applied in the field of rocket separation, can solve the problems of complex timing and large overall quality, and achieve the effect of simple timing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

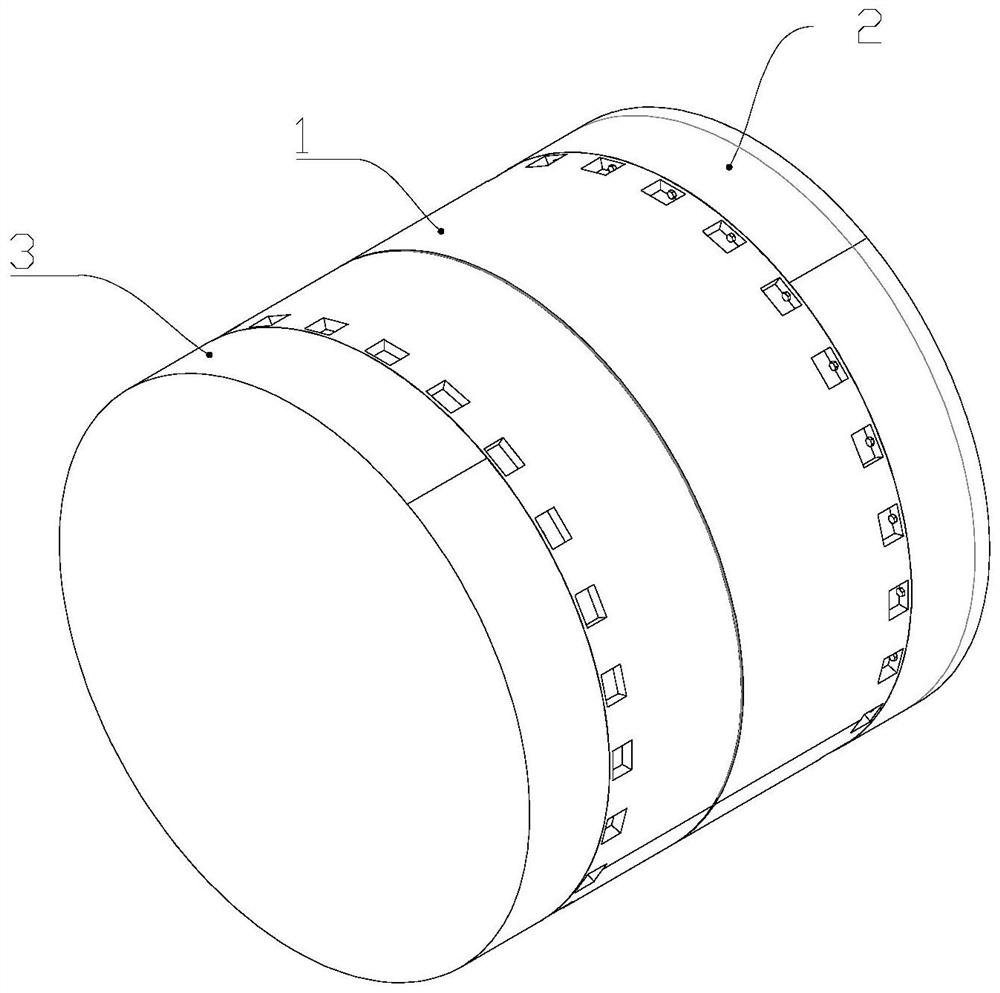

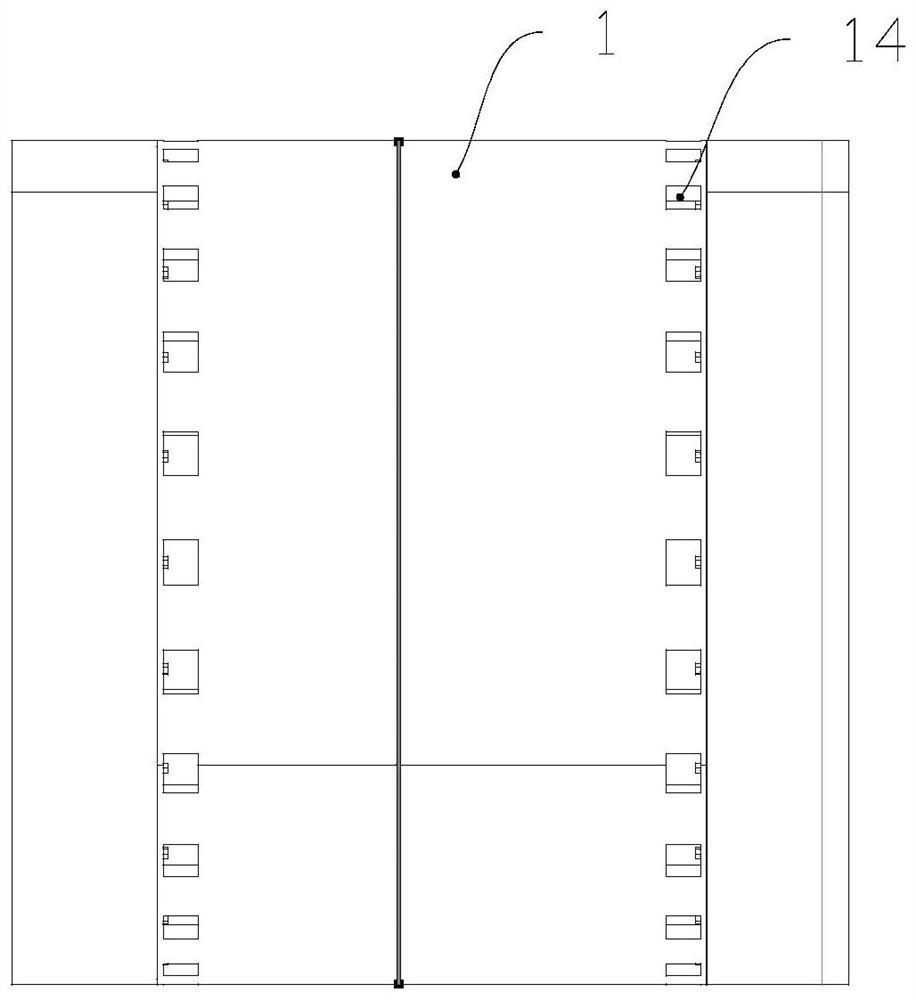

[0043] Such as Figure 1-Figure 11 As shown, a solid rocket cold separation device includes an interstage section 1, and the two ends of the interstage section 1 are respectively connected to the rear skirt 2 of the upper stage engine and the front skirt 3 of the lower stage engine to form a separable interstage The cavity is located on the interstage cavity and is provided with an upper-level engine nozzle 4 and a lower-level engine front head 5; also includes:

[0044] Airbag 6, one end of the airbag 6 extends into the nozzle pipe 4 of the upper stage engine, the other end of the airbag 6 is folded and abuts against the front head 5 of the lower stage engine, and the airbag 6 has a A one-way valve (not shown) for charging air therein;

[0045] The cutting cable assembly 7 is arranged on the interstage section 1 and is used for cutting the interstage section 1 .

[0046]The separation device described in this embodiment is located between the upper-stage engine and the lowe...

Embodiment 2

[0069] Such as Figure 4 , Figure 10 , Figure 12 Shown, a kind of using method of solid rocket cold separation device comprises the following steps:

[0070] S1. Inflate nitrogen gas into the airbag 6, so that the inflated internal pressure of the airbag 6 after folding is 1.0 atmosphere;

[0071] S2. When the rocket flies to a height of 50㎞ and when the lower stage engine finishes working, the cutting cable assembly 7 is ignited to cut the interstage section 1 into two sections;

[0072]S3. The air bag 6 expands gradually, and when expanding, the two ends of the air bag 6 generate thrusts respectively on the nozzle nozzle 4 of the upper stage engine and the front head 5 of the lower stage engine, so that the two generate relative speed and relative distance, and complete the separation;

[0073] S4. After the upper stage engine is ignited, the air bag 6 is burned under the jet flow of the upper stage engine.

[0074] In this embodiment, when separating, the cutting cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com