Direct cooling of a power converter by using a stamped plate

A technology for converters and cooling fluids, which is applied in the field of converters and can solve problems such as volume limitations and reduced output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

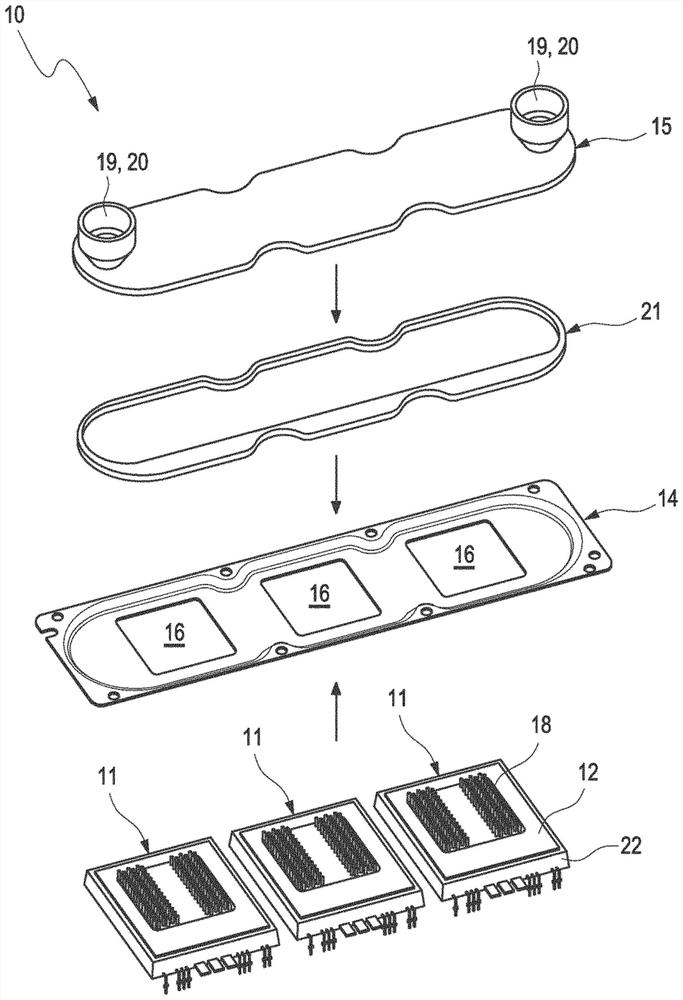

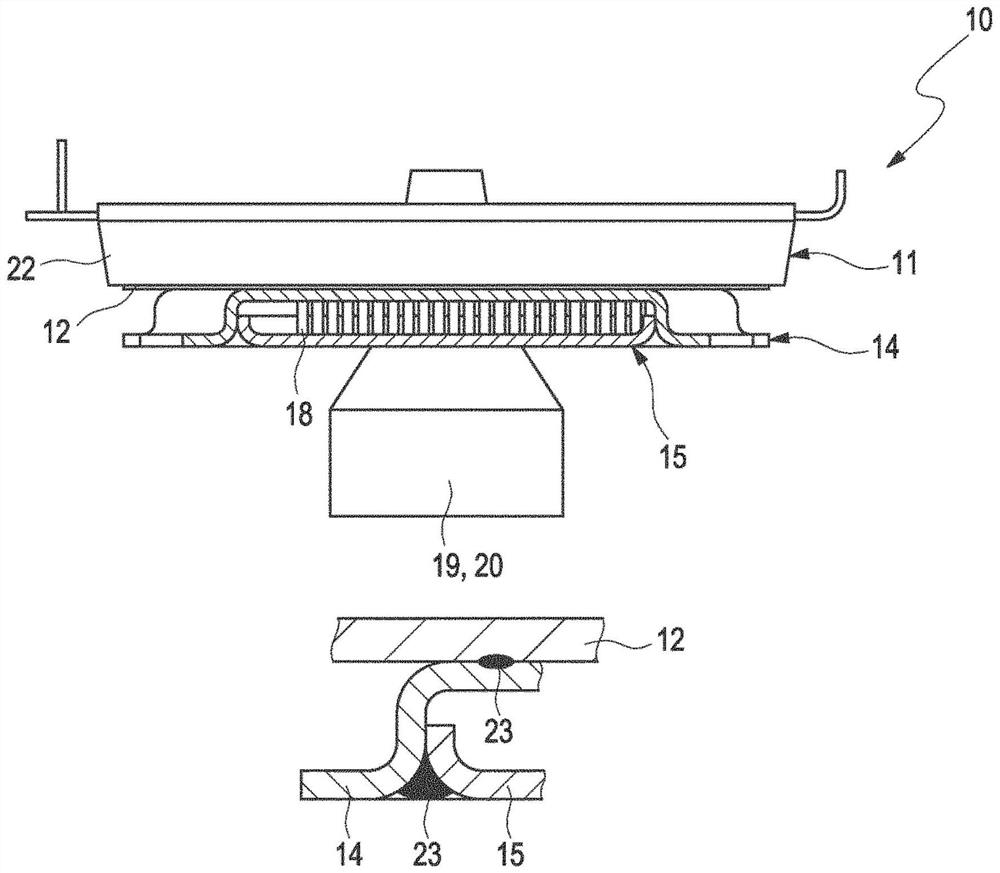

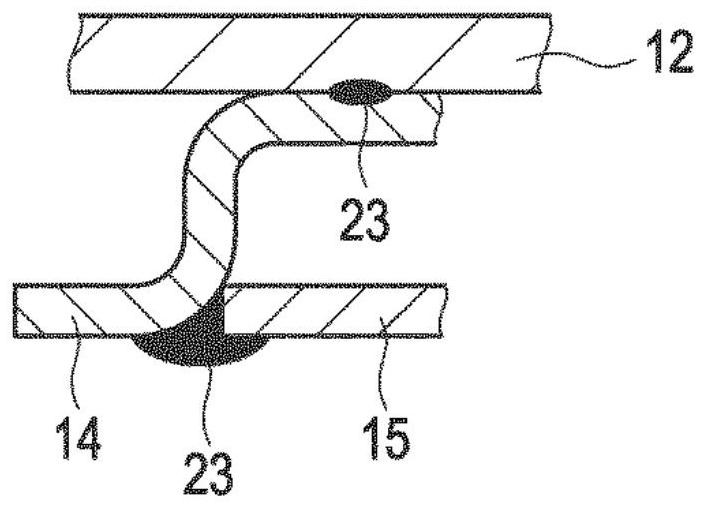

[0040] figure 1 An exploded perspective view showing the structure of the converter 10 according to the invention. Three semiconductor modules 11 are shown, each having a base 22 and a substrate 12 . Cooling fins 18 are formed on the base plate 12 . Three semiconductor modules 11 are mounted in a common receiving plate 14 , wherein receiving plate 14 has recesses 16 corresponding to the number of semiconductor modules 11 . The cutouts 16 are each configured to accommodate the semiconductor modules 11 in such a way that cooling fins 18 are arranged in the cutouts 16 .

[0041] The three semiconductor modules 11 are each soldered to the receiving plate 14 in respective connection regions formed around the recesses 16 . The receiving plate 14 is provided for receiving the bypass flow breaker 21 . The bypass flow breaker 21 can optionally be arranged in the receiving plate 14 .

[0042] The flow-through interrupter 21 is designed as an enclosure surrounding the semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com