Device for measuring the fill level in a liquid container

A liquid container and measuring device technology, applied in the field of liquid level devices, to achieve the effect of saving application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

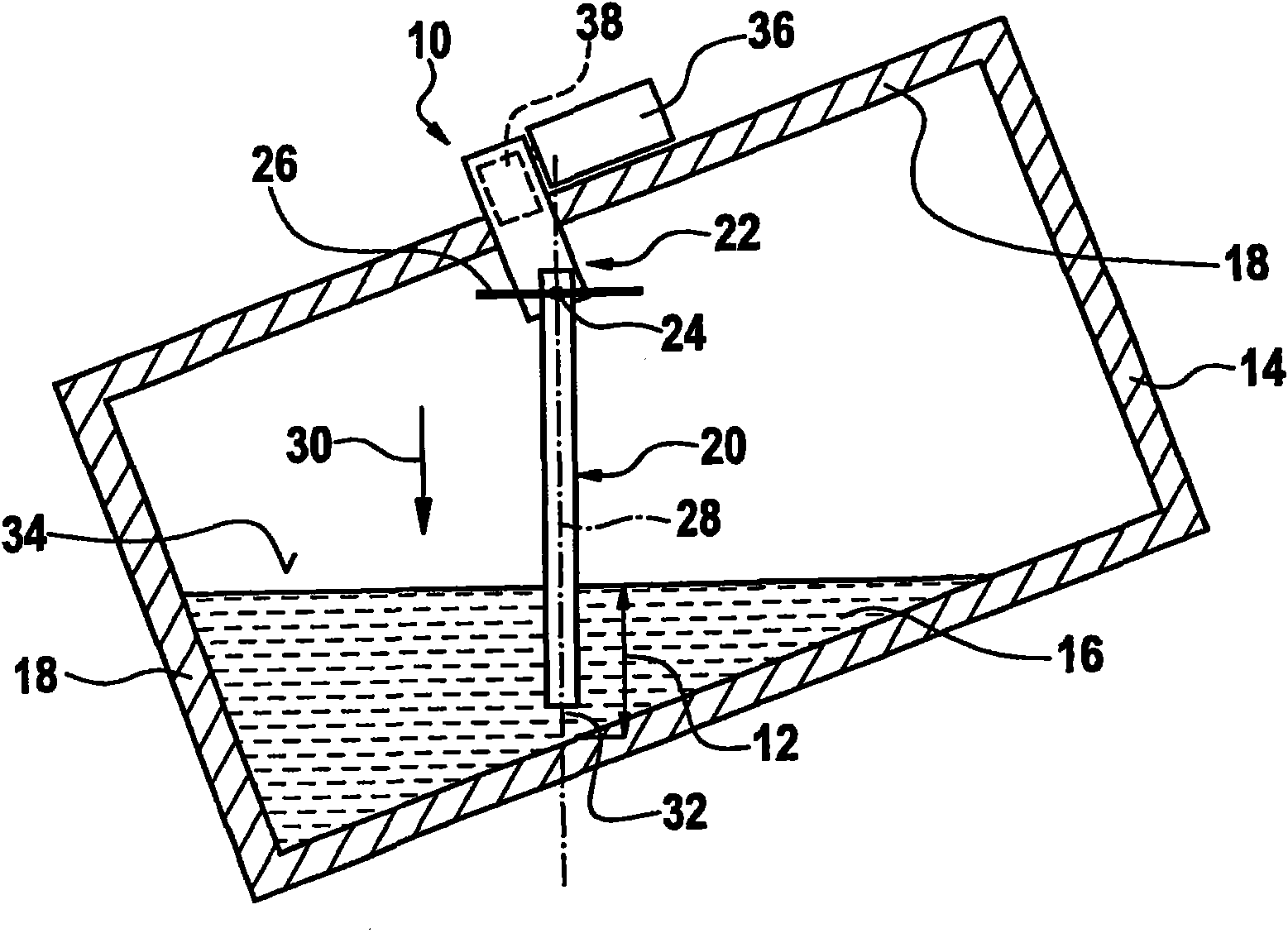

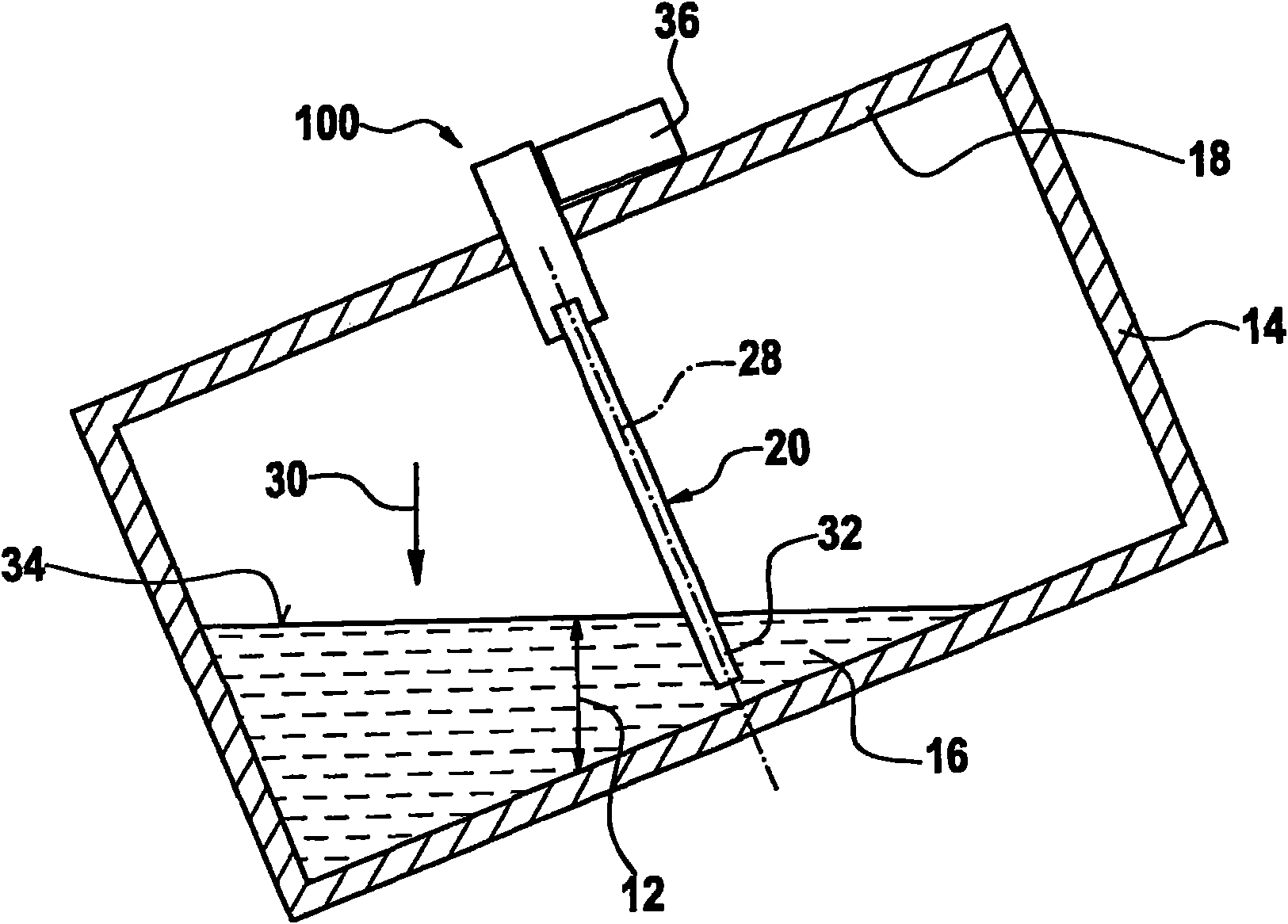

[0023] In the figures, mutually corresponding parts of different exemplary embodiments are expediently provided with the same reference symbols.

[0024] All figures show a combination that should be understood as an example—measuring device / support. The measuring devices and supports shown in each case can be combined with one another as desired.

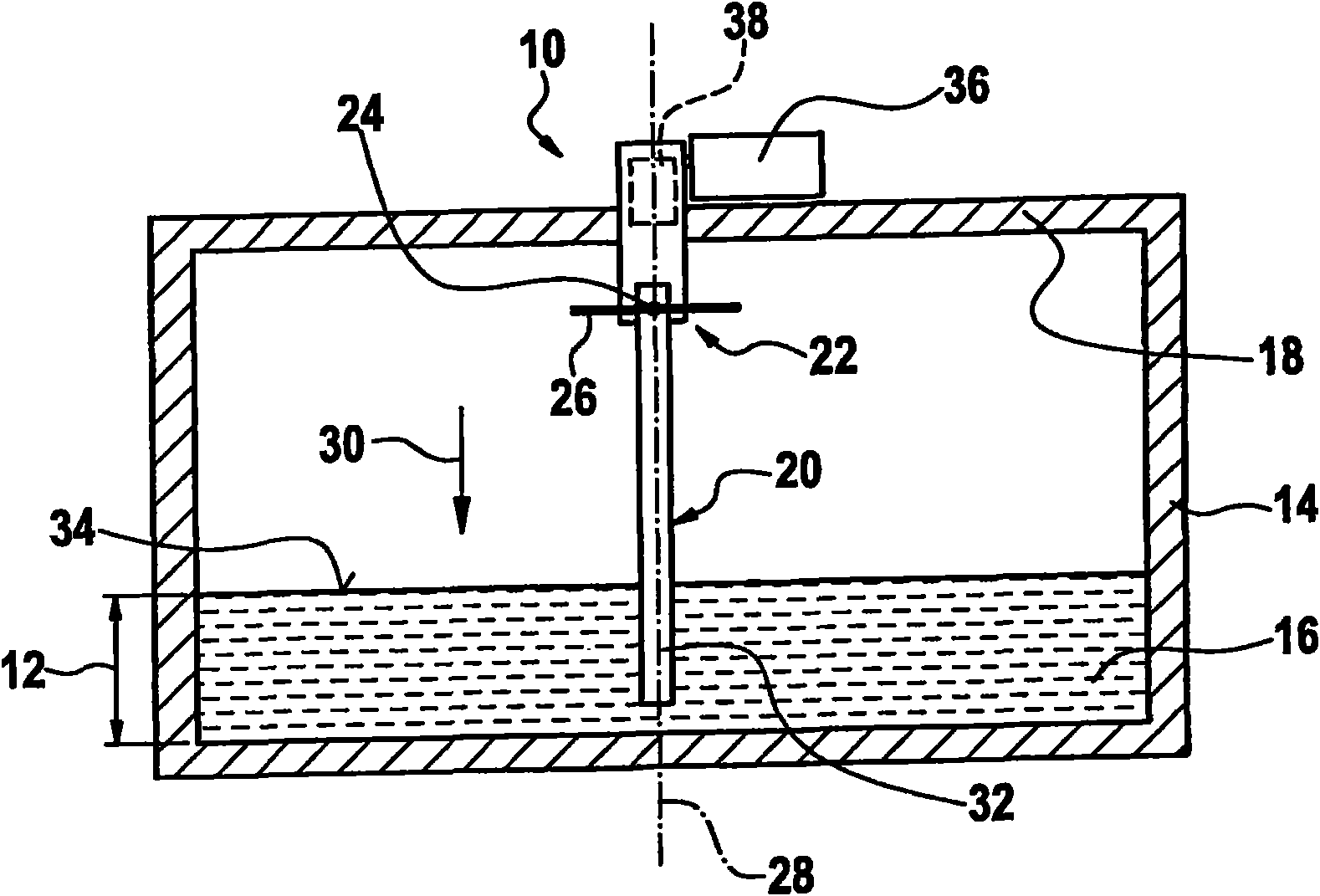

[0025] A device for measuring a liquid level 12 of a liquid 16 placed in a liquid container 14 is shown generally at 10 in the drawing. The liquid container 14 has a cover section 18 approximately in the center of which a fill level sensor 20 is arranged.

[0026] In the exemplary embodiment shown in FIG. 1 , the fill level sensor 20 is designed as a capacitive sensor which at its upper end surrounds two, Horizontal axes of rotation 24 , 26 are pivotally mounted or suspended. Liquid container 14 in Figure 1a is shown in its horizontal neutral position (Neutralstellung), while in Figure 1b It is shown in the opposite inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com