Fly ash curing method and device

A fly ash solidification and fly ash technology, which is applied in the field of fly ash solidification method and solidification device, can solve the problem that low-toxic substances cannot be completely solved, and achieve the effects of ensuring solidification landfill standards, reliable solidification, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

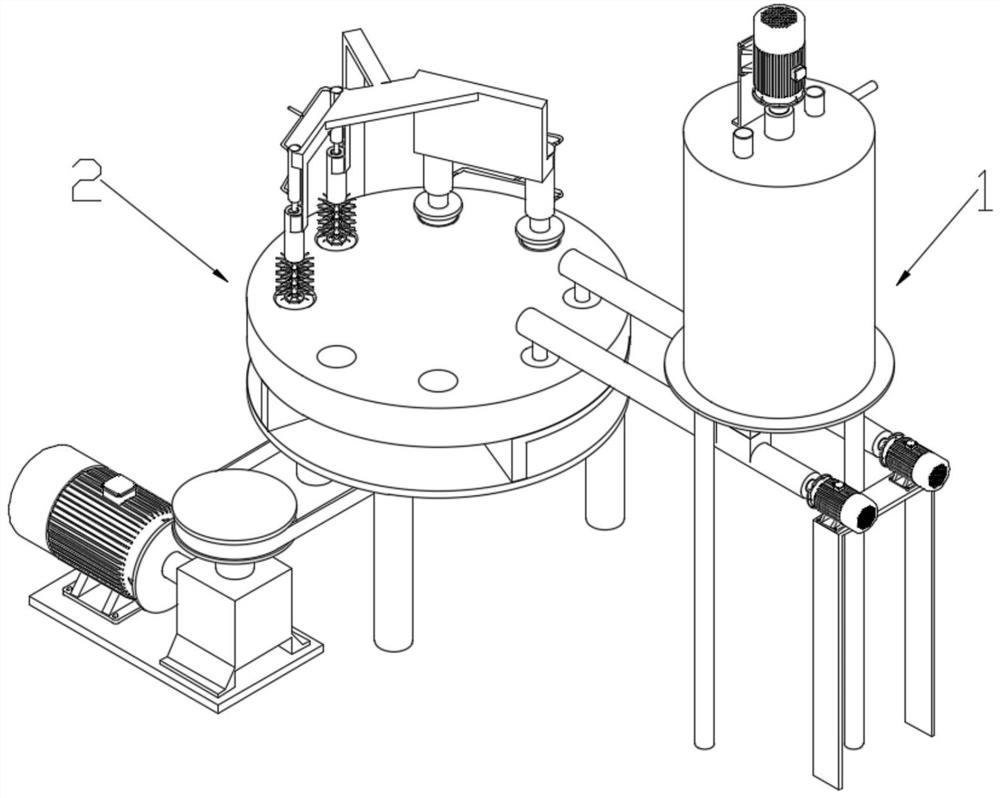

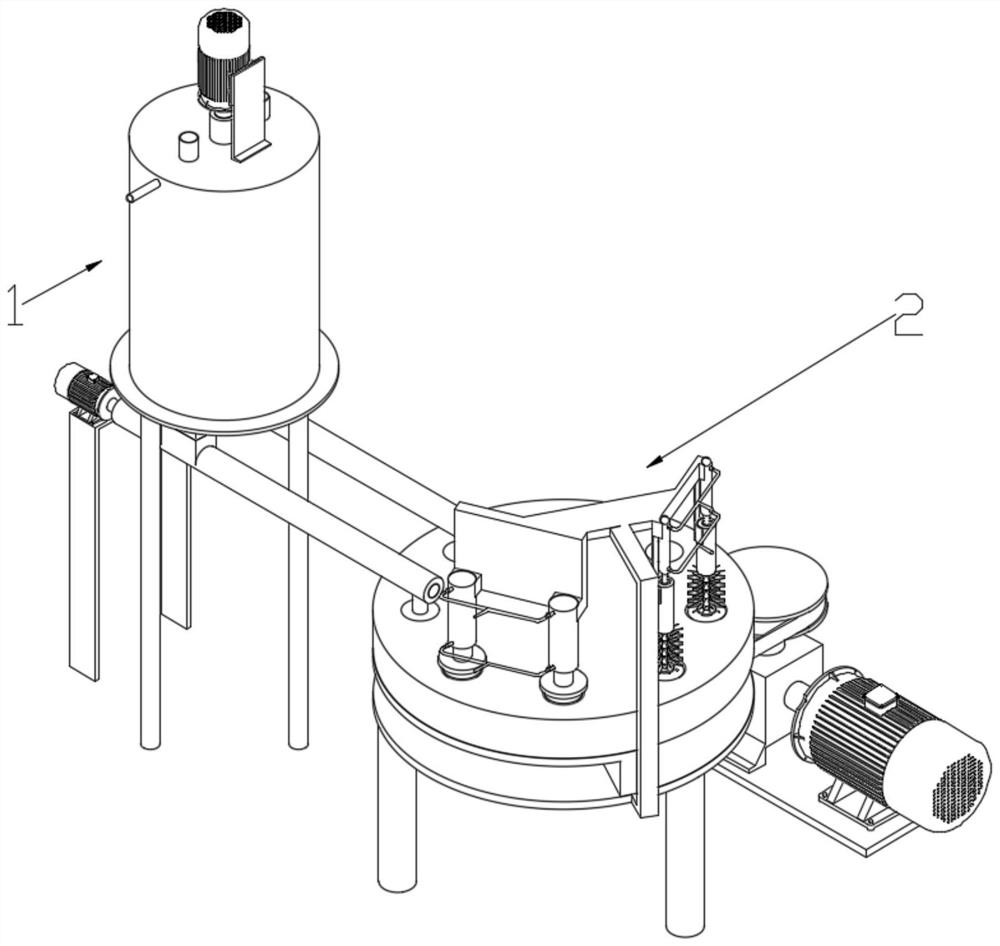

[0055] The accompanying drawings are the best embodiments of the fly ash solidification method and solidification device, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0056] Fly ash solidification material ratio, fly ash solidification materials include: fly ash, chelating agent and water, in order to further increase the solidification effect of fly ash, enhance the volatile emission and exudation of heavy metals and harmful substances in hazardous waste materials Radiation and soluble radiation have the effect of airway solidification and stability, and the materials used for fly ash solidification also include cement.

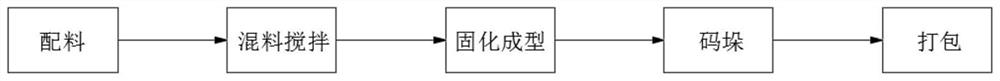

[0057] The fly ash solidification method comprises the following steps:

[0058] A. Mixing: Fly ash, chelating agent, water and cement are electronically loaded. According to their ratio, they are input into the mixing system through a metering pump, and the fly ash, chelating agent, wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com