Concrete fabricated building construction method based on BIM

A technology for building construction and concrete, which is applied in the direction of buildings, building components, building reinforcements, etc. It can solve the problems of PFC board deviation, slurry deviation, and wear of steel fixing parts, so as to increase the connection effect, improve the fixing effect, and improve the connection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

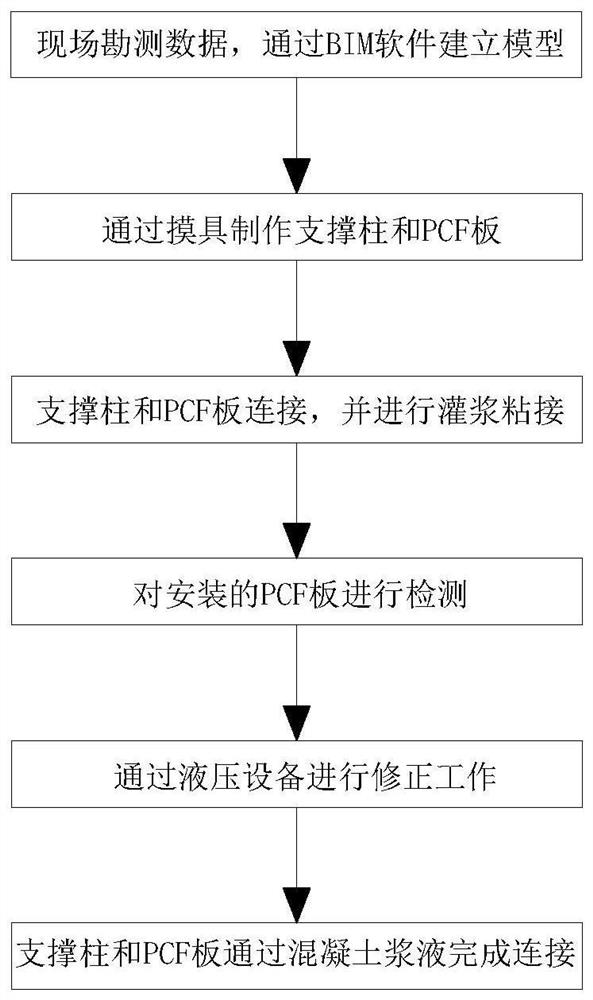

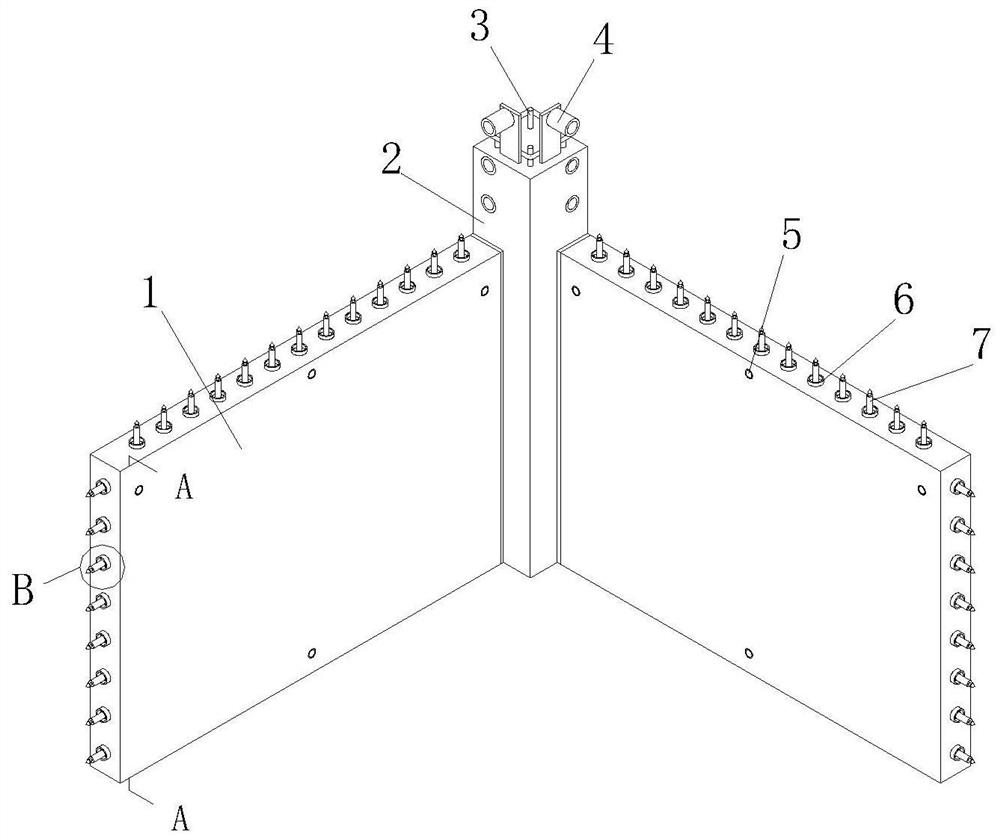

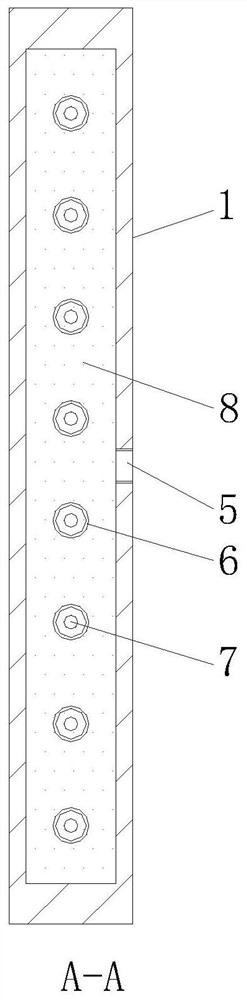

[0042] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a BIM-based concrete assembly building construction method, including the following steps;

[0043] S1: On-site survey data, and create a building model through BIM modeling software;

[0044] S2: Construct the support column on site according to the model data, and make the PCF board through the mold;

[0045] S3: Connect the PCF board to the support column, and grout and bond it through concrete;

[0046] S4: measure the spliced PCF board data;

[0047] S5: Compare the on-site measurement data with the building model data, and correct the wrong PCF board,

[0048] S6: Waiting for the bonding concrete to solidify.

[0049] Among them, in S1, it is necessary to review the 3D visualization of the model, find out the structural problems of the model, find out the errors and omissions of the model in time, and feedback the design for optimization;

[0050] In S2, the forming mold of the supporting c...

Embodiment 2

[0056] Such as figure 1 , image 3 and Figure 6 As shown, a BIM-based concrete assembly building construction method, including the following steps;

[0057] S1: On-site survey data, and create a building model through BIM modeling software;

[0058] S2: Construct the support column on site according to the model data, and make the PCF board through the mold;

[0059] S3: Connect the PCF board to the support column, and grout and bond it through concrete;

[0060] S4: measure the spliced PCF board data;

[0061] S5: Compare the on-site measurement data with the building model data, and correct the wrong PCF board,

[0062] S6: Waiting for the bonding concrete to solidify.

[0063] Among them, in S1, it is necessary to review the 3D visualization of the model, find out the structural problems of the model, find out the errors and omissions of the model in time, and feedback the design for optimization;

[0064] In S2, the forming mold of the supporting column is direc...

Embodiment 3

[0072] Such as Figure 4 As shown, a BIM-based concrete assembly building construction method, including the following steps;

[0073] S1: On-site survey data, and create a building model through BIM modeling software;

[0074] S2: Construct the support column on site according to the model data, and make the PCF board through the mold;

[0075] S3: Connect the PCF board to the support column, and grout and bond it through concrete;

[0076] S4: measure the spliced PCF board data;

[0077] S5: Compare the on-site measurement data with the building model data, and correct the wrong PCF board,

[0078] S6: Waiting for the bonding concrete to solidify.

[0079] Among them, in S1, it is necessary to review the 3D visualization of the model, find out the structural problems of the model, find out the errors and omissions of the model in time, and feedback the design for optimization;

[0080] In S2, the forming mold of the supporting column is directly laid on site, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com