Prefabricated bottom plate with removable ribs and production method of laminated plate

A production method and technology for laminated panels, which are applied to floors, buildings, building components, etc., can solve the problems of high production difficulty, inability to disassemble, and unfavorable promotion, and achieve the effect of saving materials, saving materials, and reducing the amount of on-site manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention are provided below to help further understanding of the present invention. Those skilled in the art should understand that the descriptions of the embodiments of the present invention are only exemplary, and are not intended to limit the solution of the present invention.

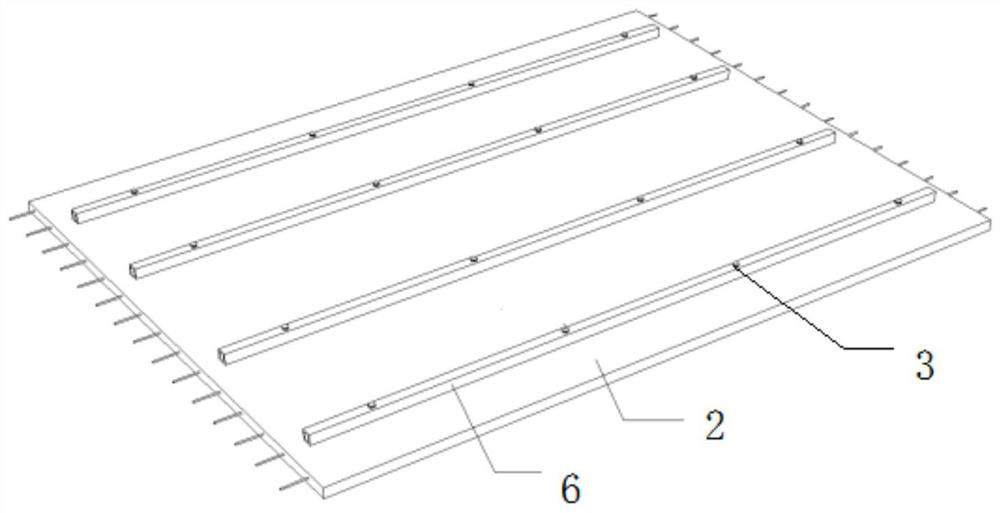

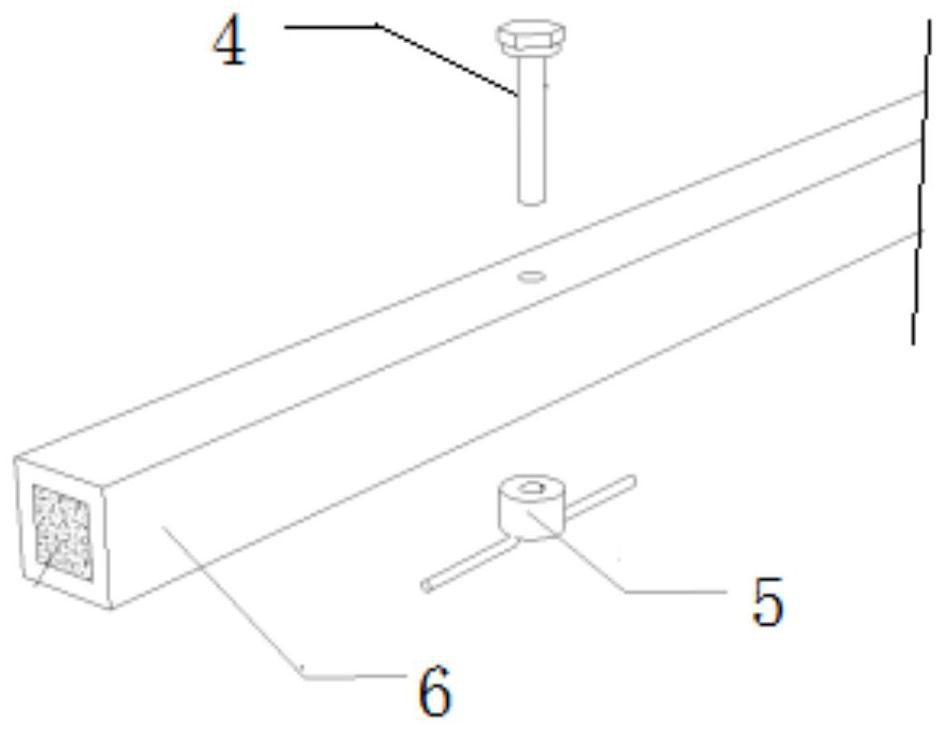

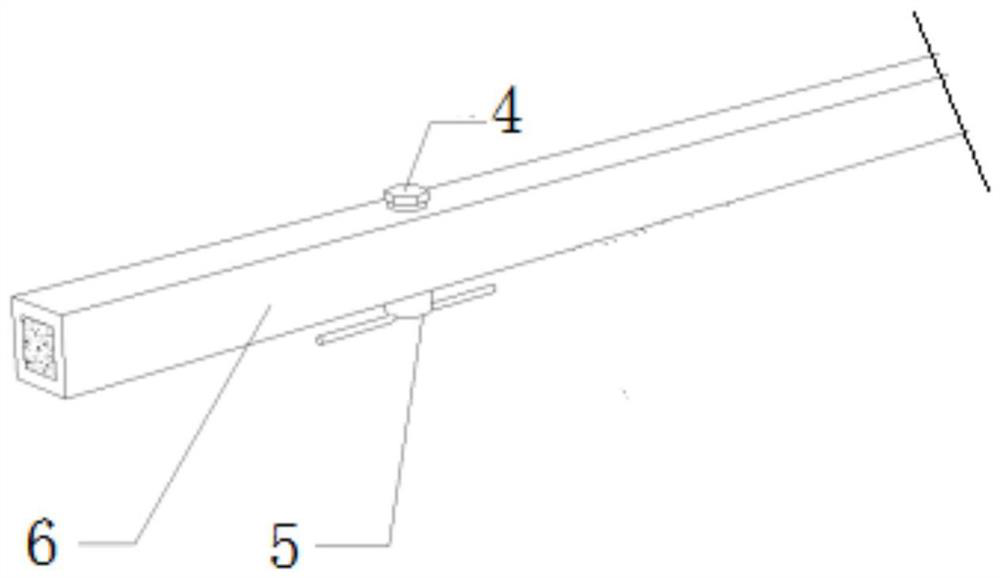

[0039] See attached figure 1 to attach image 3 For illustration, the prefabricated bottom slab with removable ribs 1 in an embodiment of the present invention includes a concrete slab 2 and at least two removable ribs 1 fixed on the concrete slab 2, and the removable ribs 1 include internally poured High-strength mortar square steel pipe 6, embedded parts and fixing parts 3, the square steel pipe 6 is set on the surface of the concrete slab 2, the embedded parts are anchored in the concrete slab 2, the fixing parts 3 pass through the square steel pipe 6 and are connected with the embedded parts ; Concrete slabs 2 are pre-embedded with reinforced mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com