Combined use of air-oil separator and oil filter in systems requiring oil separation and filtration

An oil separator, filter technology, applied in the direction of dispersed particle filtration, separation method, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] This invention relates to the operation of air-oil separators and oil filters used in systems requiring oil separation and filtration on a single block. In other words, the present invention discloses an oil separation and filtration system having an air-oil separator and an oil filter.

[0037] Thanks to the invention, energy losses are reduced and a more compact system is provided for use.

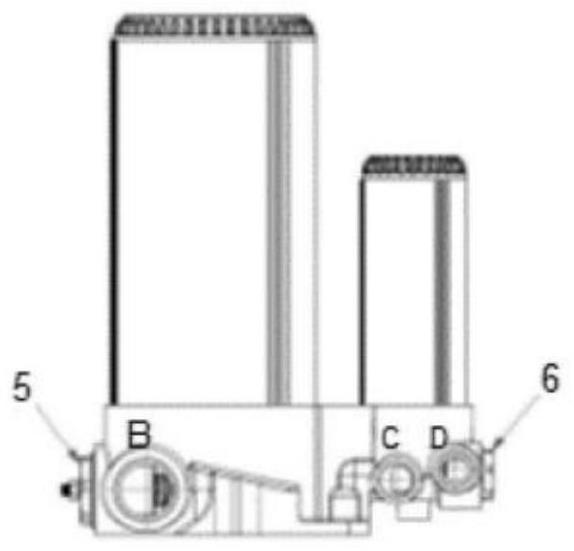

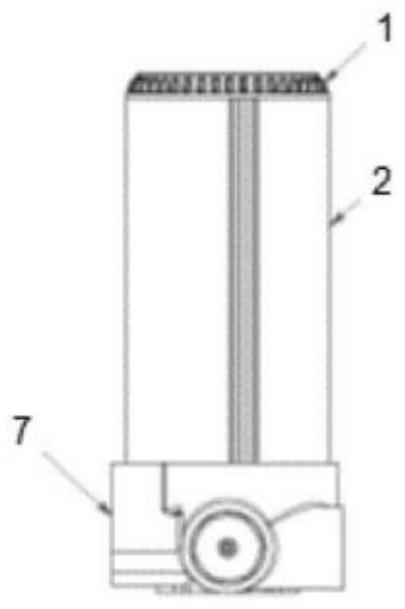

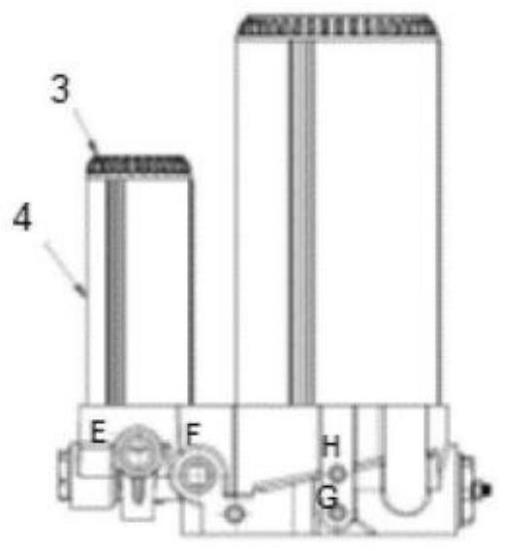

[0038] According to the system of the invention, the system basically comprises an air-oil separator element (27), an oil filter element (10), a minimum pressure valve (5), a temperature valve (6) and blocks connected to these components ( 7).

[0039] In the drawings of the present invention, Port A-Port G are provided.

[0040] The general principle of operation of the system according to the invention is as follows:

[0041] Air passes through port A ( Figure 1D ) into the air-oil separator section. An air-oil separator element (27) in the first housing (2) separates air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap