Electric wire pay-off device

A technology of pay-off device and wire, applied in transportation and packaging, cable laying equipment, transportation of filamentous materials, etc., can solve the problems of manual moving, pulling back to a place dozens of meters away, laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

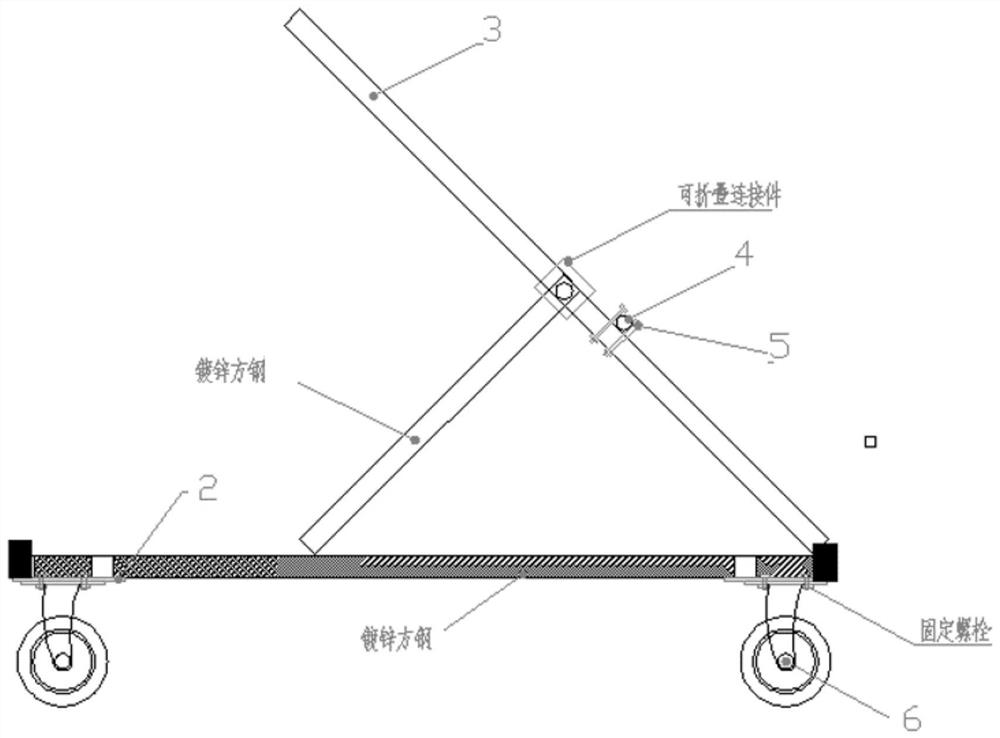

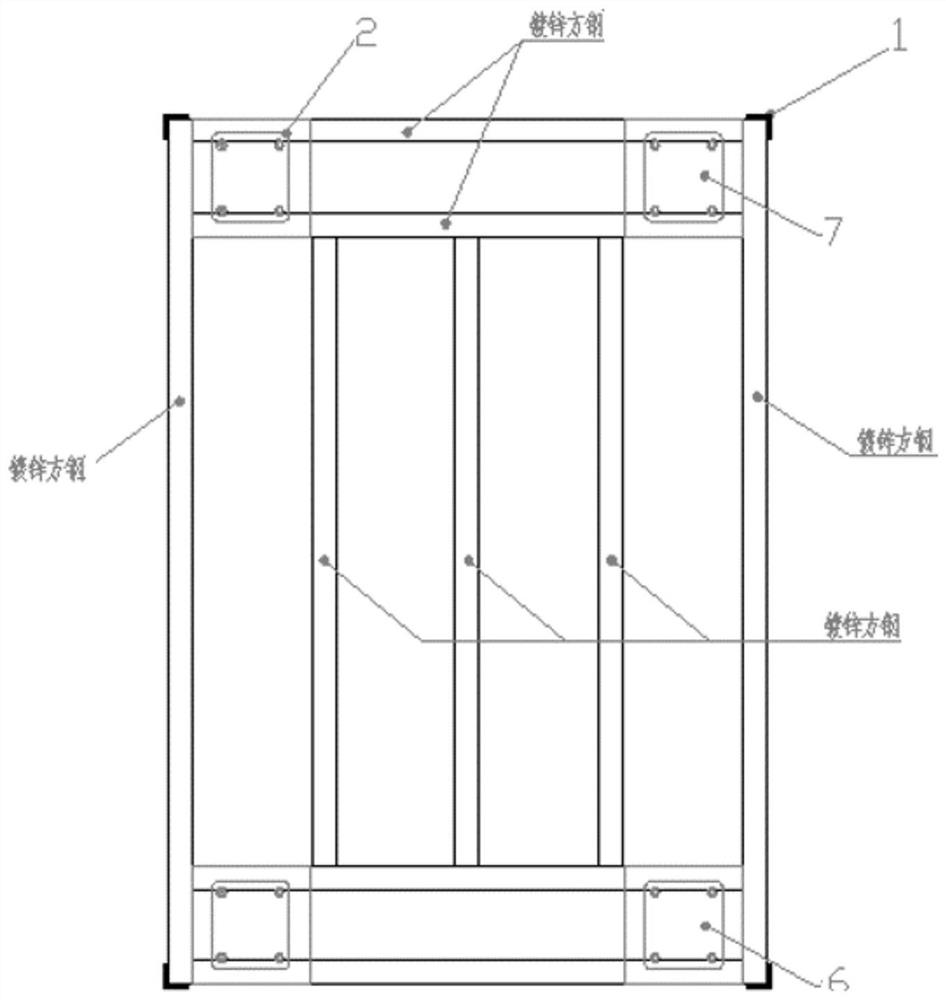

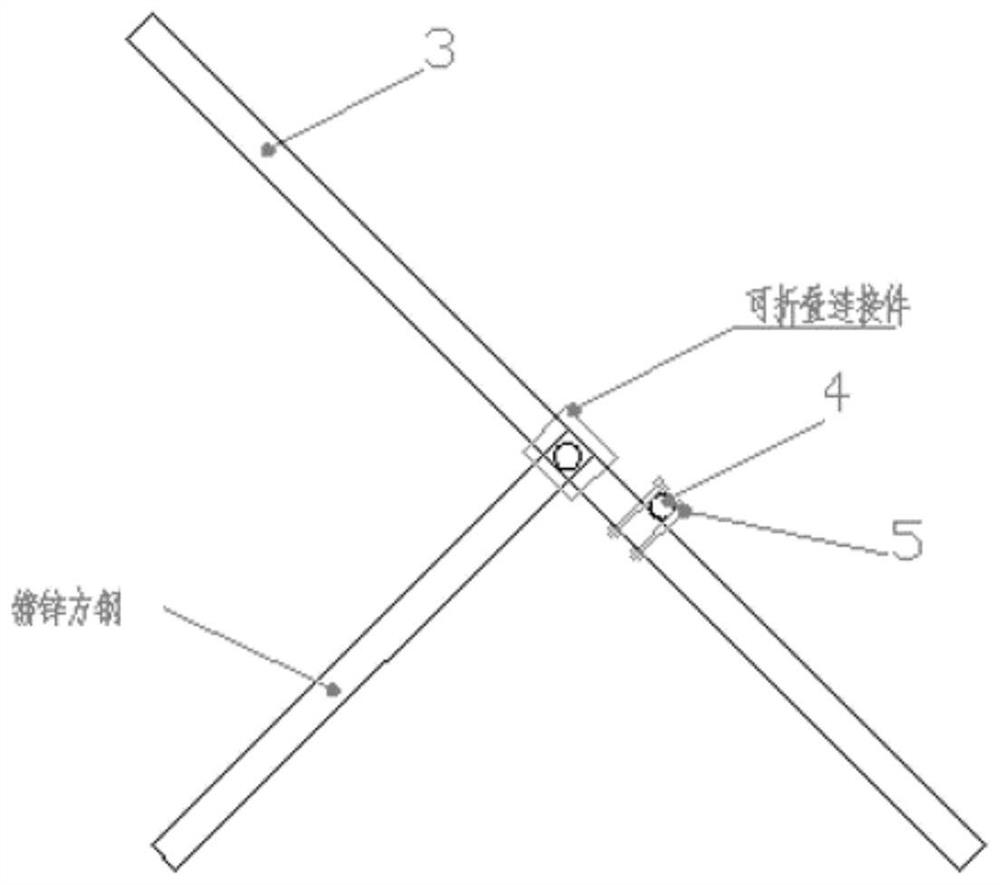

[0024] Such as Figure 1-Figure 4 Shown: a wire pay-off device, including angle steel 1, steel plate 2, galvanized square steel 3, galvanized steel pipe (thickened) 4, screw nut, directional wheel (with brake) 6, universal wheel (with brake) )7;

[0025] Angle steel 1 is welded to the four corners of the rectangular main frame to fix the pay-off device; steel plate 2 is welded to the four corners of the bottom side of the rectangular main frame to fix the wheels; galvanized square steel 3 is used to weld the entire The main frame and the frame of the pay-off device; the galvanized steel pipe (thickened) 4 is used on the pay-off device as the rotating bearing pressure tube of the winding reel, and is fixed by bolts; the bolt and nut 5 are used in the four main bracket The angled steel plate is used to fix the wheel, as well as the overlapping joint of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com