Gas flow process detection device and method, air compressor unit and detection method

An air compressor unit and process detection technology, applied in the detection field, to achieve the effect of comprehensive evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

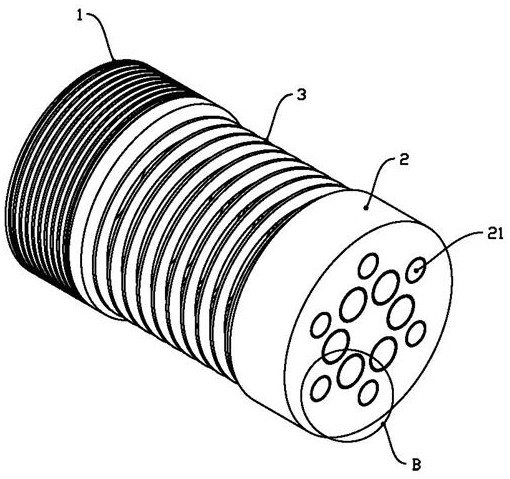

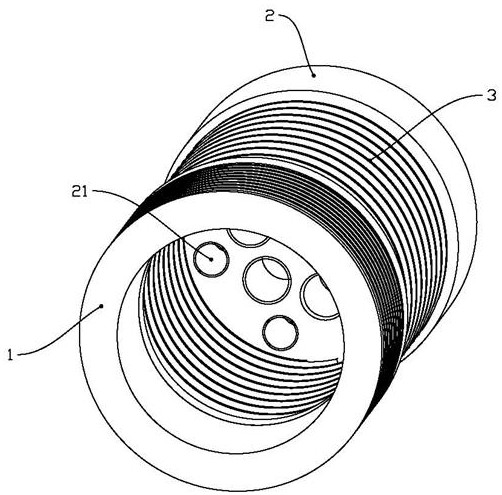

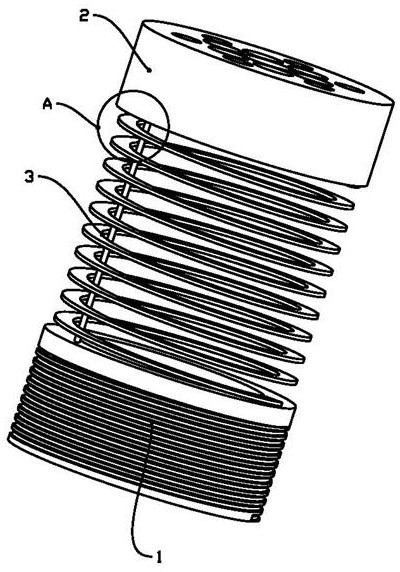

[0049] Such as Figure 1~6As shown, the gas flow process detection device includes: a mounting base 1, which is fixedly connected to the inner wall of the pipeline, and a through passage 11 for gas circulation is provided in the middle; The inner wall of the road is bonded, and the bonding position is sealed. The induction structure 2 is provided with a number of flow passages 21 for the gas to flow to the through passage 11; the buffer structure 3 is arranged between the mounting base 1 and the induction structure 2. For the induction structure 2 Elastic cushioning is performed relative to the movement of the mounting base 1; the probe 4 is fixedly connected to the mounting base 1 or the sensing structure 2, and detects the distance of the sensing structure 2 relative to the mounting base 1; the sensing structure 2 includes an elastic body 22 and a guide The trachea 23 and the elastic body 22 are attached to the inner wall of the pipeline, and have a closed cavity inside, fil...

Embodiment 2

[0058] The gas flow process detection method adopts the gas flow process detection device in Embodiment 1, takes time as the abscissa, and the length value of the probe 4 as the ordinate to establish a coordinate system, determines points on the coordinate system through the collected data, and connects Each point and through the trend reflect the flow process of gas.

[0059] In the present invention, the type of data collected is relatively simple, compared with the way of comprehensively analyzing and comparing multiple sets of data in the prior art to obtain conclusions, it is more intuitive. The fluctuation of the position and the change of the expansion state due to fluctuations convert the imperceptible gas flow state in the pipeline into a visually recognizable trend line form, thus making the detection conclusion more intuitive.

[0060] Such as Figure 7 As shown, the width range between the two sets of parallel dotted lines at the top and bottom of the figure is th...

Embodiment 3

[0070] Such as Figure 9~11 As shown, the air compressor unit includes the gas flow process detection device in Embodiment 1, and the sequentially connected compressor unit 7, air storage tank 8 and drying unit 9; the compressor unit 7 includes several groups of compression units 71, at least one compressor Unit 71 is used as a spare unit, and the air intake position and the air outlet position of compression unit 71 are respectively provided with a first-stage filter structure 72 and a second-stage filter structure 73; the drying unit 9 includes several groups of drying units 91, at least one drying unit 91 is used as a backup unit, and the air intake position and the air outlet position of the drying unit 91 are respectively provided with a third-stage filter structure 92 and a fourth-stage filter structure 93 .

[0071] Wherein, the pipelines at the outlets of the first-stage filter structure 72 , the second-stage filter structure 73 , the third-stage filter structure 92 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com