Aviation product MBOM health degree evaluation method oriented to manufacturing process

A technology of manufacturing process and evaluation method, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of inability to evaluate accuracy and timeliness, limited scope of verification, and single evaluation index, so as to avoid data errors and omissions. The effect of timely discovery, avoidance of repeated comparison work, and improvement of manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

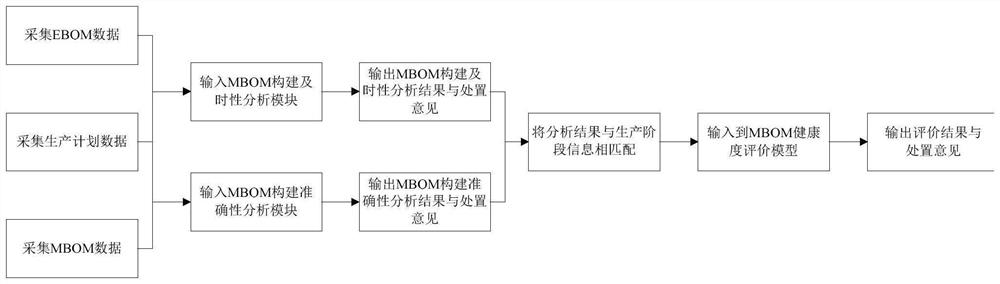

[0059] like image 3 As shown, this embodiment involves a data acquisition module, an MBOM construction timeliness analysis module, an MBOM construction accuracy analysis module, an MBOM health evaluation module, and an evaluation result and disposition opinion output module in the MBOM health evaluation method for aviation products.

[0060] The data acquisition module collects EBOM data, MBOM data, and production sorties information at different manufacturing stages, and constructs a data set.

[0061] The MBOM construction timeliness analysis module compares the number of components, finished products, and standard parts of MBOM and EBOM for the entire flight, and identifies objects with differences in the comparison results. Object, validity, disposition opinion of MBOM, and calculation of overdue days. Count the number of overdue items according to the set period of overdue days, and calculate the timely rate of MBOM construction of aviation products in the test flight s...

Embodiment 2

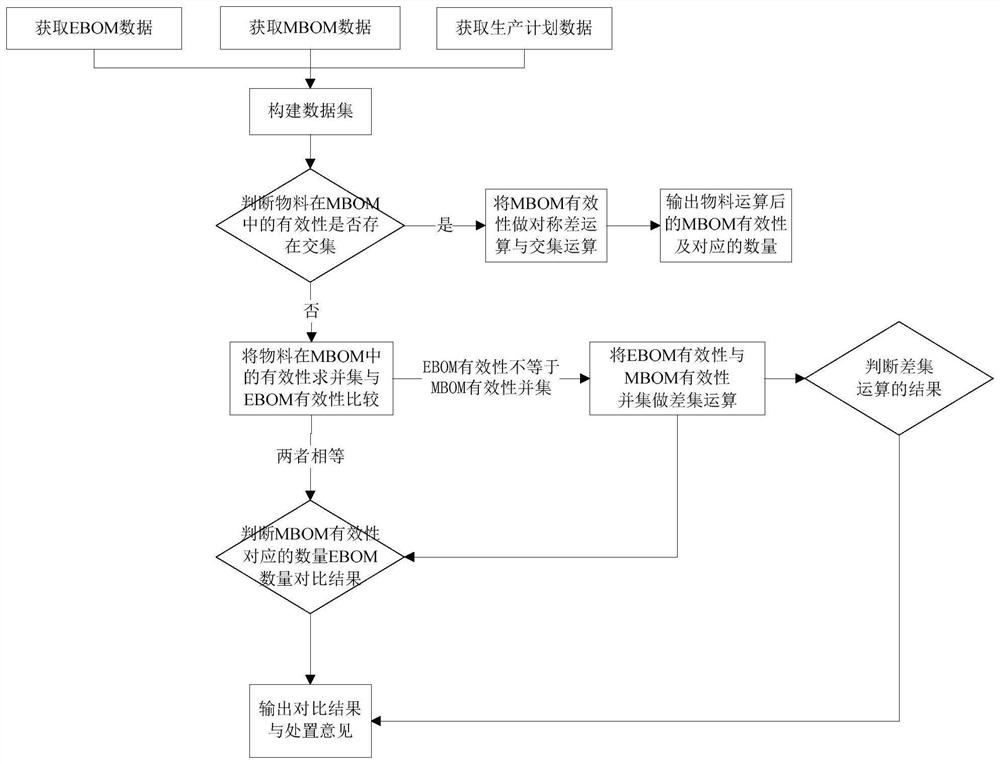

[0075] like figure 1 As shown, the specific steps of this embodiment are as follows:

[0076] a. Collect EBOM data, MBOM material consumption data, and production flight information data at different manufacturing stages.

[0077] b. Denote the EBOM path corresponding to one of the obtained map numbers as M, and denote the EBOM validity corresponding to M as E E , if M cannot find the corresponding EBOM validity, E E Recorded as 0; if M can find the corresponding EBOM validity, E E is the specific validity interval, E E denoted as E M1 ,E M2 …E Mn , denote the MBOM validity corresponding to M as E M , if M cannot find the corresponding MBOM validity, E M Recorded as 0; if M can find the corresponding MBOM validity, E M is a specific validity interval. will E E The corresponding EBOM quantity is recorded as A E , will get E M The corresponding MBOM quantity is recorded as A M , and record the EBOM release date data corresponding to M as T;

[0078] c. Traverse th...

Embodiment 3

[0089] A manufacturing process-oriented MBOM health evaluation method for aviation products, comprising the following steps:

[0090] Step 1: Collect EBOM data, MBOM data of aviation products and production sorties information at different manufacturing stages;

[0091] Step 2: Construct a dataset according to the collected data;

[0092] The obtained EBOM and the EBOM path data corresponding to all the MBOM map numbers are formed into a set, which is denoted as M, and M is expressed as: M={M 1 ,M 2 ,M 3 ,…M n }, will get M 1 The corresponding EBOM validity data forms a set, denoted as E 1E , E 1E Represented as: E 1E ={E 1E }, if M cannot find the corresponding EBOM validity, E 1E Recorded as 0, if M can find the corresponding EBOM validity, E 1E is a specific validity interval. will get M 1 The corresponding MBOM validity data forms a set, denoted as E 1M , E 1M Represented as: E 1M ={E 1M1 ,E 1M2 …E 1Mn }, if M 1 The corresponding MBOM validity cannot be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com