Graphene mica heating plate manufacturing process

A production process, the technology of graphene mica, applied in the field of graphene mica heating plate production process, to achieve long life, ensure normal operation and use, and solve the effects of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

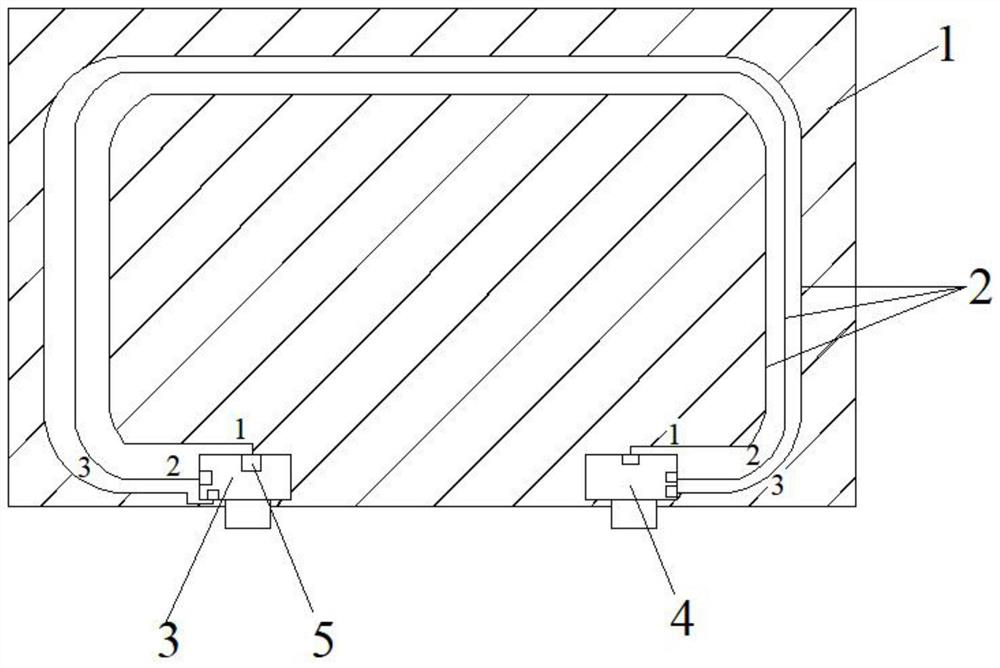

[0014] see figure 1 , a kind of graphene mica heating board manufacturing process according to the embodiment of the present invention, comprises the following steps:

[0015] Divide the heating metal wire of the high-power large-scale heating plate installed on the graphene mica substrate plate 1 into n small power loops 2, and spread the n low power loops 2 in parallel with each other on a graphene mica substrate Inside the board 1, the two ends of the parallel n small power circuits 2 are connected to the cathode terminal 4 and the anode terminal 3 of the total output and input respectively, and the cathode terminal 4 and the anode terminal 3 are arranged on the graphene mica substrate board 1 Inside one end of the small power circuit 2, nickel alloy sheets 5 are connected to both ends of the small power circuit 2 and the nickel alloy sheets 5 of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com