Reciprocating type stirring device

A stirring device, reciprocating technology, applied in the directions of transportation and packaging, dissolving, mixer, etc., can solve the problems of low stirring efficiency, insufficient stirring, and layering of materials up and down, so as to improve the stirring effect and improve the stirring efficiency. , reduce the effect of power source devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

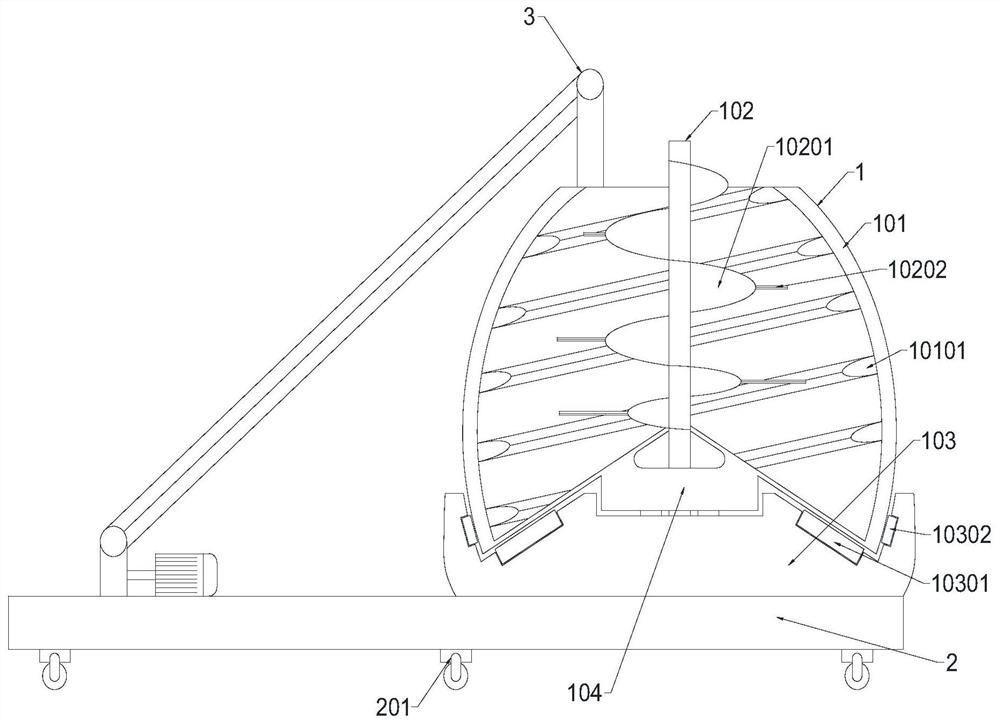

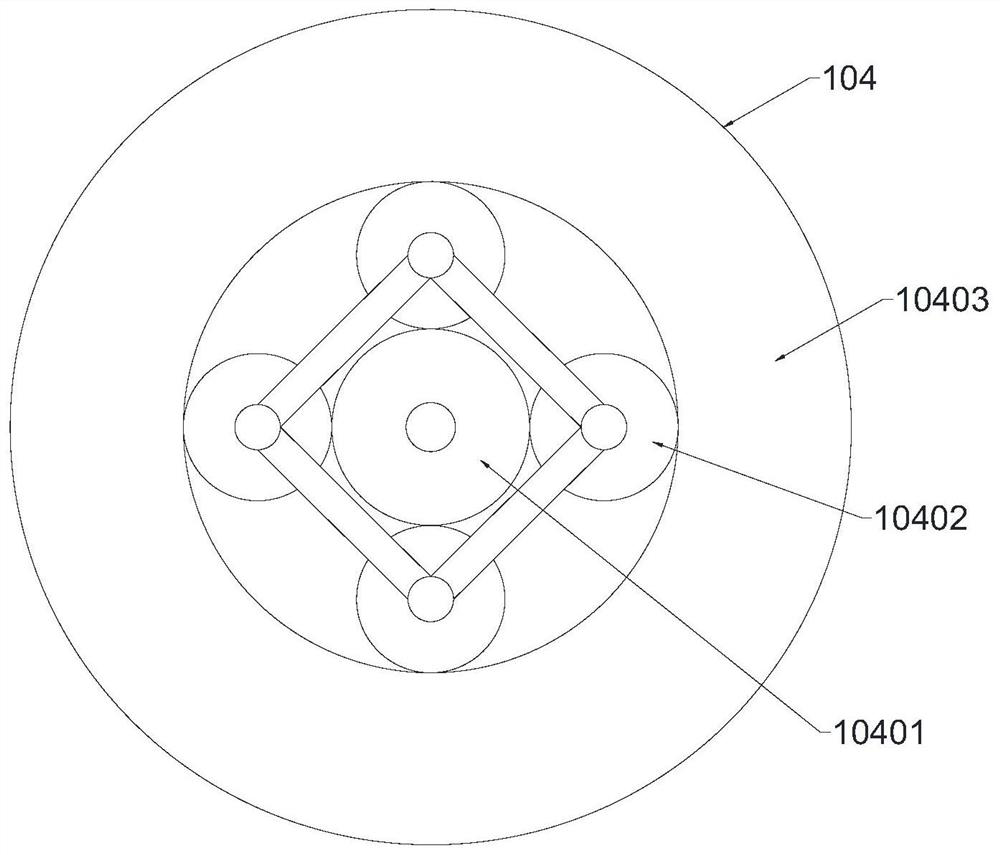

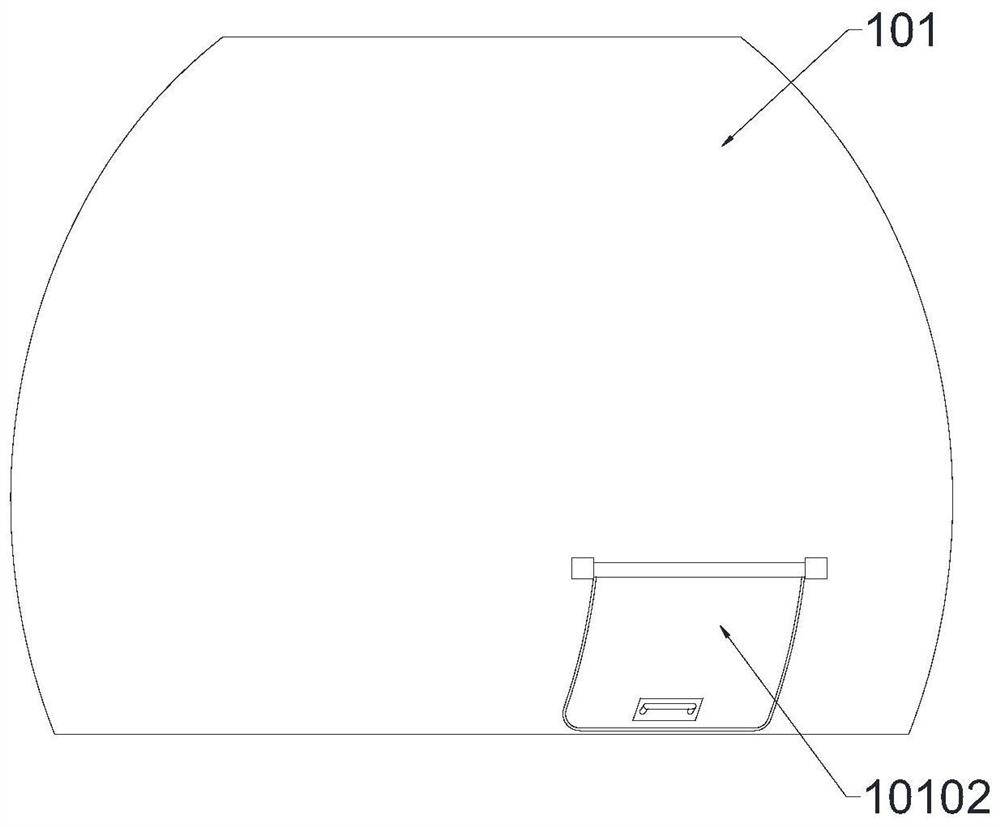

[0027] combined with Figure 1-3 , a reciprocating stirring device, including a stirring module 1, a moving seat 2 and a feeding module 3, the stirring module 1 and the feeding module 3 are fixed on the moving seat 2, and the stirring module 1 includes a shell 101 , a stirring shaft 102, a base 103 and a planetary gear system 104, the top of the housing 101 is provided with a feed port connected to the feeding module 3, the stirring shaft 102 is located on the central axis of the housing 101, the The stirring shaft 102 is rotatably connected to the casing 101 and the planetary gear system 104, the rotation direction of the casing 101 and the stirring shaft 102 is opposite, and the inner surface of the casing 101 is provided with a helical first blade 10101 The peripheral side of the stirring shaft 102 is provided with a helical second blade 10201, the base 103 is provided with a driving mechanism connected with the stirring shaft 102, and the planetary gear system 104 includes...

Embodiment 2

[0040] A kind of reciprocating stirring device of this embodiment, compared with the technical scheme of embodiment 1, can be improved as follows: feed module 3 adopts pipeline transportation, considers that some materials themselves are not easy to be transported by conveyor belt, such as water, liquid For materials, etc., the pipeline is connected with a pump body, and the materials that are not easy to be transported by the conveyor belt can be added to the stirring device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com